10 Heads Facial Mask Filling Sealing Machine

Facial Mask Packing MachinePRODUCT PARAMETERS

|

Action flow |

Automatic unloading, automatic filling, automatic sealing, finished product output |

|

number of channels |

10(can be controlled individually) |

|

Productivity |

13000PCS/H |

|

Mask Bag Specifications |

Width 80-165mm Length 90-225mm |

|

Standard filling pump |

Electronic gear pump |

|

Filling accuracy |

±0.2g |

|

Mains &Power |

Mains:380V/50-60Hz Power:8KW |

|

air pressure |

0.6Mpa 700L/min |

|

Equipment size |

2800*1000*1750mm(Climbing belt not included) |

Multiple Heads

The design featuring 10 heads allows for concurrent filling, which considerably boosts the packing speed of facial masks.

Precise Measurement

The design featuring 10 heads allows for concurrent filling, which considerably boosts the packing speed of facial masks.

Hygienic Nature

Constructed from materials that are simple to clean, it sustains a top - notch hygienic environment for beauty items.

User - Friendly Design

The straightforward operation interface enables workers to swiftly learn and handle the machine effortlessly.

Space - Efficient

Its compact structure means it takes up less room in the factory while still offering excellent functionality.Technical Features

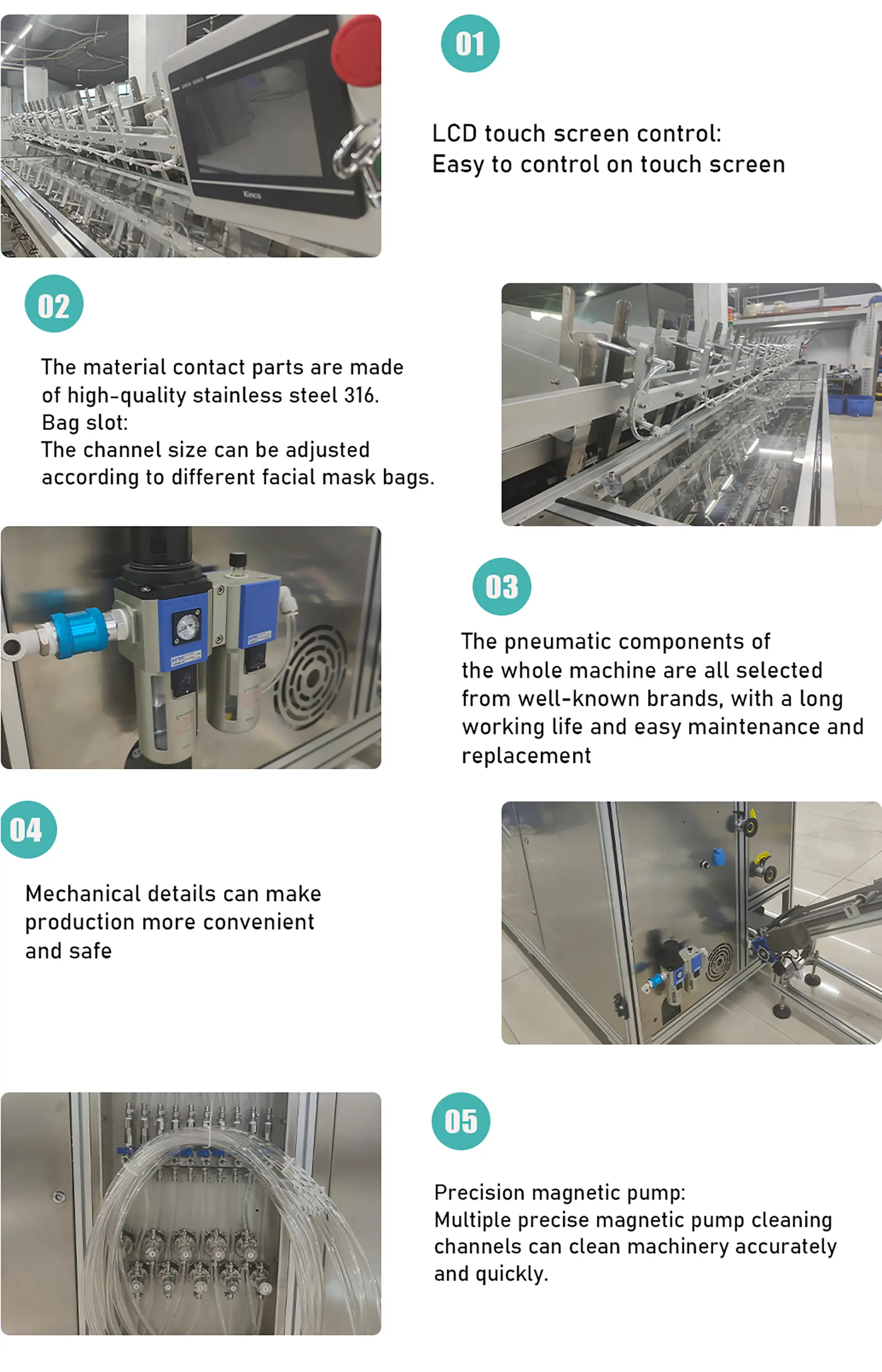

1.The machine has the ability to automatically unload, fill, seal, code, and output products.

2.The parts in contact with the objects are made of 316 stainless steel, meeting GMP standards.

3.When there are no bags, neither filling nor sealing operations will be performed, and the sealed bags won't stick to each other.

4.Controlled by PLC + LED touch screen, the equipment parameters can be easily set on the screen, and the productivity and error information are clear.

5.Temperature control is realized through digital display.

6.The electrical and pneumatic components are selected from world - famous brands.

2.The parts in contact with the objects are made of 316 stainless steel, meeting GMP standards.

3.When there are no bags, neither filling nor sealing operations will be performed, and the sealed bags won't stick to each other.

4.Controlled by PLC + LED touch screen, the equipment parameters can be easily set on the screen, and the productivity and error information are clear.

5.Temperature control is realized through digital display.

6.The electrical and pneumatic components are selected from world - famous brands.

Product Details

Product Applications

1. Cosmetic manufacturing plants for large - scale facial mask production to meet market demands.

2. Beauty product research facilities to test new mask formulas during filling and packing processes.

3. Contract manufacturing companies specializing in facial mask production for various brands.

4. Small - scale beauty businesses that want to start their own mask production lines.

5. Industrial parks dedicated to beauty and personal care product manufacturing.

2. Beauty product research facilities to test new mask formulas during filling and packing processes.

3. Contract manufacturing companies specializing in facial mask production for various brands.

4. Small - scale beauty businesses that want to start their own mask production lines.

5. Industrial parks dedicated to beauty and personal care product manufacturing.