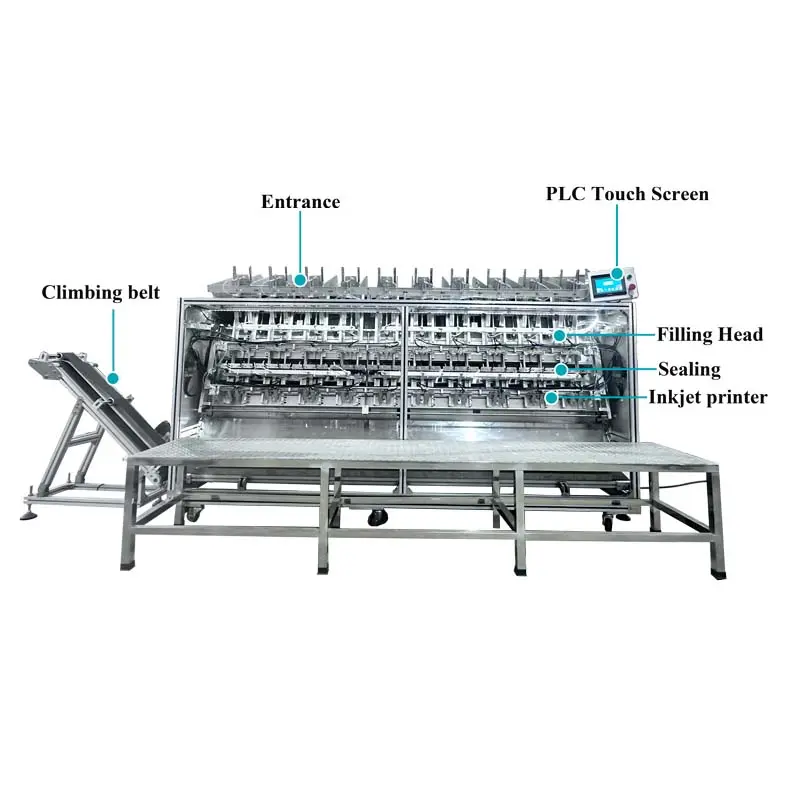

10 Heads Facial Mask Packaging Machine

Facial Mask Packing MachinePRODUCT PARAMETERS

|

Action flow |

Automatic unloading, automatic filling, automatic sealing, finished product output |

|

number of channels |

10(can be controlled individually) |

|

Productivity |

13000PCS/H |

|

Mask Bag Specifications |

Width 80-165mm Length 90-225mm |

|

Standard filling pump |

Electronic gear pump |

|

Filling accuracy |

±0.2g |

|

Mains &Power |

Mains:380V/50-60Hz Power:8KW |

|

air pressure |

0.6Mpa 700L/min |

|

Equipment size |

2800*1000*1750mm(Climbing belt not included) |

10 Heads Configuration

The unique 10-head design enables simultaneous filling, remarkably accelerating the packaging pace of facial masks.

10 Heads Arrangement

The 10-head layout empowers parallel filling, greatly enhancing the facial mask packaging velocity.

Sanitary Quality

Made of easily cleanable materials, it preserves an excellent hygienic condition for cosmetic products.

Intuitive Operation Design

The simple and clear operation panel allows workers to quickly master and use the machine with ease.

Space - Saving

With a compact and condensed structure, it occupies minimal space in the factory without compromising its outstanding functionality.Technical Features

1.This machine is capable of automatically unloading, filling, sealing, coding, and outputting products, streamlining the entire production process.

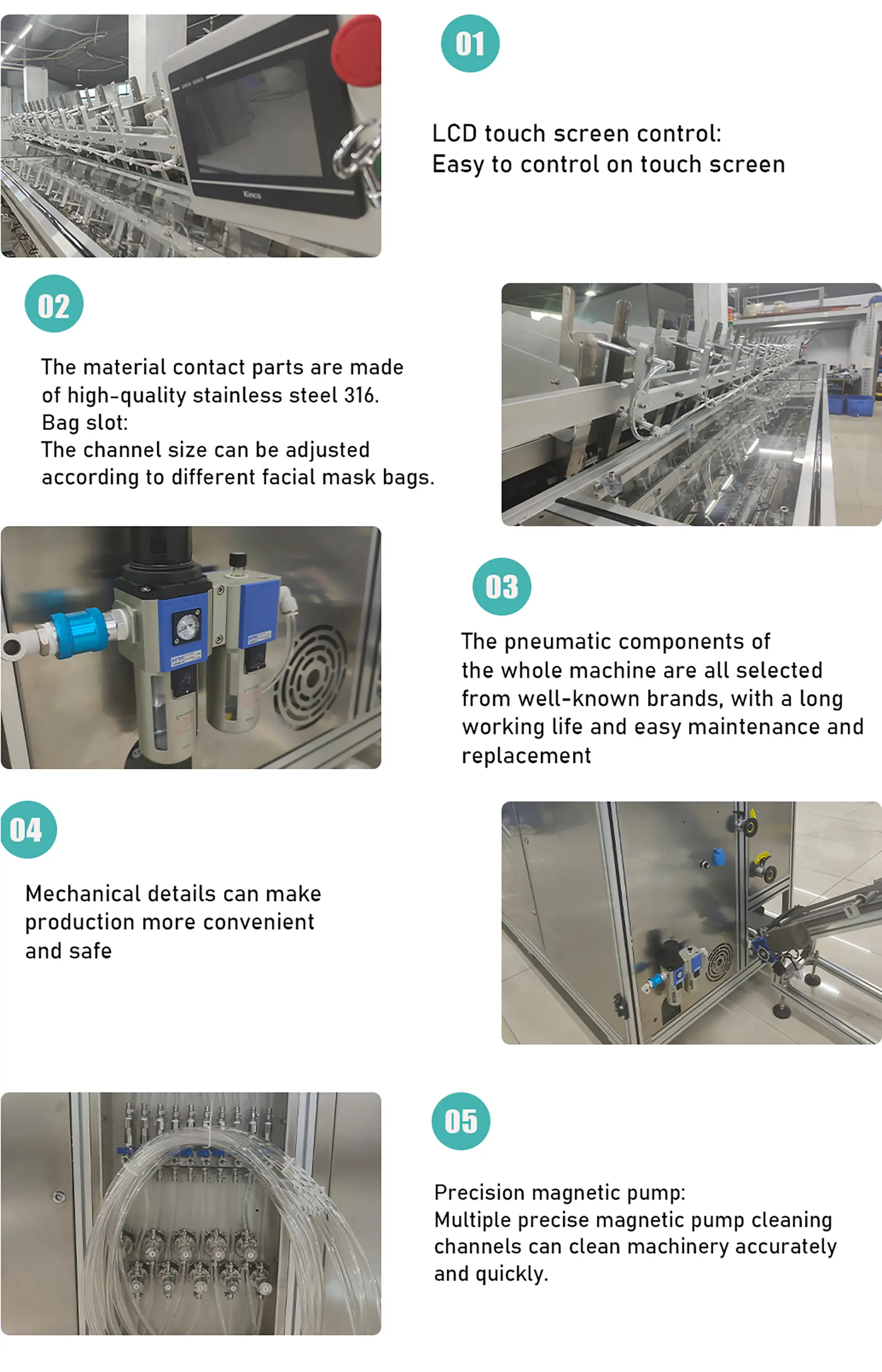

2.The components that come into contact with the items are crafted from 316 stainless steel, fully compliant with GMP standards to ensure product quality and safety.

3.In the absence of bags, the machine will halt both filling and sealing procedures, preventing sealed bags from adhering to one another.

4.Operated by PLC + LED touch screen, the equipment parameters can be effortlessly configured on the display, with clear productivity and error details for easy monitoring.

5.Temperature regulation is achieved via digital display, offering precise control for optimal sealing results.

6.The electrical and pneumatic parts are sourced from globally renowned brands, guaranteeing reliable performance and durability.

2.The components that come into contact with the items are crafted from 316 stainless steel, fully compliant with GMP standards to ensure product quality and safety.

3.In the absence of bags, the machine will halt both filling and sealing procedures, preventing sealed bags from adhering to one another.

4.Operated by PLC + LED touch screen, the equipment parameters can be effortlessly configured on the display, with clear productivity and error details for easy monitoring.

5.Temperature regulation is achieved via digital display, offering precise control for optimal sealing results.

6.The electrical and pneumatic parts are sourced from globally renowned brands, guaranteeing reliable performance and durability.

Product Details

Product Applications

1. Cosmetic manufacturing plants can utilize this machine for large-scale facial mask production. Its high efficiency and automated functions are perfect for meeting the surging market demands, ensuring a steady supply of quality masks.

2. In beauty product research facilities, it plays a crucial role. When testing new mask formulas, the machine's precise filling and packing capabilities during the R&D stage provide accurate data on product performance and packaging integrity.

3. Contract manufacturing companies specializing in facial masks for diverse brands will find it indispensable. It can quickly adapt to different brand requirements, churning out perfectly packaged masks with speed and precision.

4. For small-scale beauty businesses looking to launch their own mask production lines, this machine offers an affordable yet powerful solution. Its user-friendly design allows even novice operators to get up to speed fast.

5. Industrial parks centered around beauty and personal care product manufacturing can house multiple units of this machine. Its space-efficient design and reliable performance make it a top choice for high-volume production environments.

2. In beauty product research facilities, it plays a crucial role. When testing new mask formulas, the machine's precise filling and packing capabilities during the R&D stage provide accurate data on product performance and packaging integrity.

3. Contract manufacturing companies specializing in facial masks for diverse brands will find it indispensable. It can quickly adapt to different brand requirements, churning out perfectly packaged masks with speed and precision.

4. For small-scale beauty businesses looking to launch their own mask production lines, this machine offers an affordable yet powerful solution. Its user-friendly design allows even novice operators to get up to speed fast.

5. Industrial parks centered around beauty and personal care product manufacturing can house multiple units of this machine. Its space-efficient design and reliable performance make it a top choice for high-volume production environments.