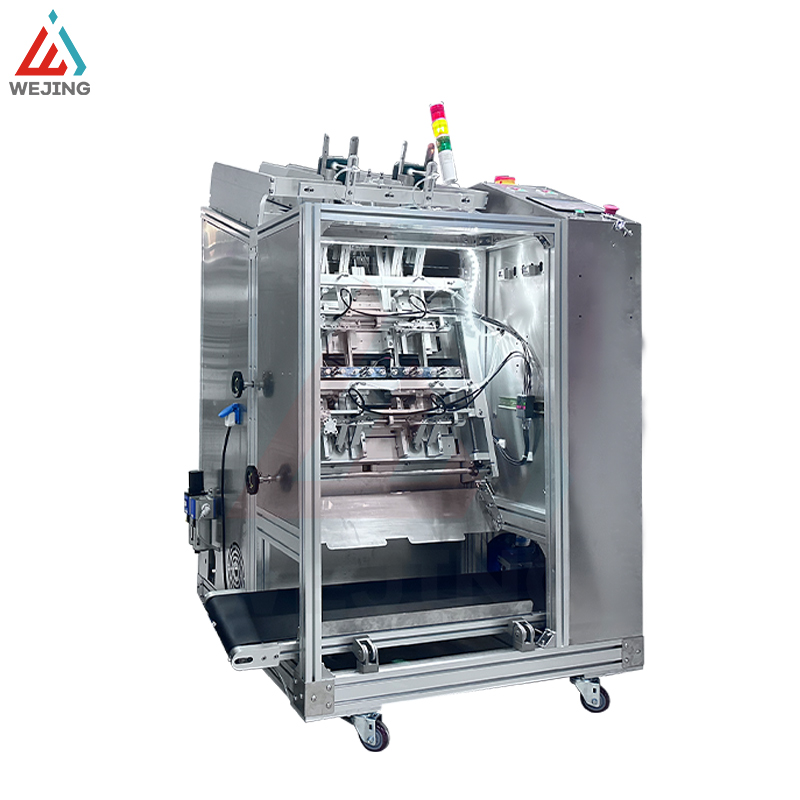

2 Heads Facial Mask Filling Machine

Facial Mask Packing MachinePRODUCT PARAMETERS

|

Action flow |

Automatic unloading, automatic filling, automatic sealing, finished product output |

|

number of channels |

2(can be controlled individually) |

|

Productivity |

2000-2500PCS/H |

|

Mask Bag Specifications |

Width 85-160mm Length 110-220mm |

|

Standard filling pump |

Electronic gear pump |

|

Filling accuracy |

±0.2g |

|

Mains &Power |

Mains:380V/50Hz Power:5KW |

|

air pressure |

0.6Mpa 300L/min |

|

Equipment size |

L750*1050*1720mm(Climbing belt not included) |

Ultra-High-Speed Filling

Equipped with two state-of-the-art filling heads, this remarkable machine can rapidly fill a large quantity of facial masks concurrently. It maximizes productivity as it swiftly dispenses the precise amount of essence into each mask, propelling the production process to new heights and meeting high-volume demands with ease.

Precision Control

It guarantees pinpoint accuracy in the liquid volume dispensed into every single facial mask. By doing so, it effectively curtails any potential waste, ensuring that resources are utilized optimally and each mask receives the exact amount of liquid required for top-notch quality.

Reliable Functioning

During extended periods of operation, this machine functions flawlessly. It maintains a consistent level of production quality, ensuring that every facial mask produced adheres to the highest standards, with no fluctuations or disruptions to the manufacturing process.

Versatile Utility

It demonstrates remarkable adaptability and is ideally suited for a diverse array of liquids utilized in the production of beauty facial masks. Whether it's a thick serum or a lightweight essence, this machine can handle them all, catering to the varied formulation needs of the cosmetics industry.

Technical Features

1. Automatic Integrated Process

2. Premium Material Compliance

3. Intelligent Bag-Dependent Operation

4. Intuitive Control Interface

5. Precise Digital Temperature Regulation

6.High-Quality Component Selection

The machine is engineered to execute unloading, filling, sealing, coding, and output procedures in a seamless, automated fashion. This streamlines the production line, reducing manual intervention and enhancing overall efficiency.

2. Premium Material Compliance

Constructed with 316-grade stainless steel for all item-contact components, it strictly adheres to GMP regulations. This not only ensures durability but also safeguards product purity throughout the manufacturing process.

3. Intelligent Bag-Dependent Operation

It operates on an intelligent mechanism where filling and sealing are conditional on the presence of bags. Moreover, the sealed bags possess a non-stick property, preventing any messy adhesion and guaranteeing a smooth production flow.

4. Intuitive Control Interface

Featuring a PLC + LED touch-screen control system, operators can effortlessly configure equipment parameters. The screen vividly displays productivity metrics and error alerts, facilitating real-time monitoring and prompt adjustments.

5. Precise Digital Temperature Regulation

Temperature control is achieved via advanced digital display technology. This enables precise adjustment and maintenance of the desired temperature, crucial for the quality of the facial mask liquid.

The electrical and pneumatic elements are sourced from globally recognized brands. This choice underpins the machine's reliability, performance, and longevity, ensuring consistent operation in the long run.

Product FAQ

1.What's the simultaneous filling capacity of this machine?

Equipped with two highly efficient heads, it has the ability to fill two facial masks concurrently, optimizing the production tempo.

2.Does it possess the versatility to handle diverse liquid formulations?Absolutely. It demonstrates excellent adaptability and can work with a wide range of liquids designed for beauty facial masks, meeting various production demands.

3.What material is used for the parts that come into contact with substances?The components making contact with materials are crafted from 316-grade stainless steel, strictly conforming to GMP standards to ensure product safety and quality.

4.What kind of control system does it employ?It utilizes a state-of-the-art PLC + LED touch-screen control mechanism. This allows operators to manipulate the equipment with great ease and precision.

5.Is there a function for temperature regulation?Yes, it features digital display temperature control technology. This empowers users to accurately adjust and monitor the temperature, which is vital for maintaining the integrity of the mask liquid.

6.How about the origin of its electrical components?The electrical and pneumatic parts are carefully selected from globally esteemed brands, guaranteeing reliable performance and durability.