3 in 1 Semi Auto Aerosol Machine

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Capacity |

600-1200 cans/hr,depending on filing volume |

|

Liquid filling capacity |

30-500ml(can be choose) |

|

Gas filling capacity |

30-500ml(can be choose) |

|

Filling accuracy |

≤±1% |

|

Applicable can diameter |

40-70mm |

|

Suitable aerosol can height |

70-300mm |

|

Air source |

0.5-0.6Mpa |

Automatic Bag On Valve Aerosol Filling MachineWorking Process

Usually driven by pneumatic means. The material is extracted and ejected by driving the piston with a cylinder, and the flow direction of the material is controlled by a one-way valve. The stroke of the cylinder is controlled by a magnetic spring switch, thereby achieving adjustment of the filling volume. After liquid materials are filled into the aerosol tank, propellant gas (such as propyl butane gas, freon, dimethyl ether and 134a) is filled to make the tank reach a certain pressure, so that the liquid can be sprayed out in the form of spray during use.

Automatic Bag On Valve Aerosol Filling MachineStructural Composition

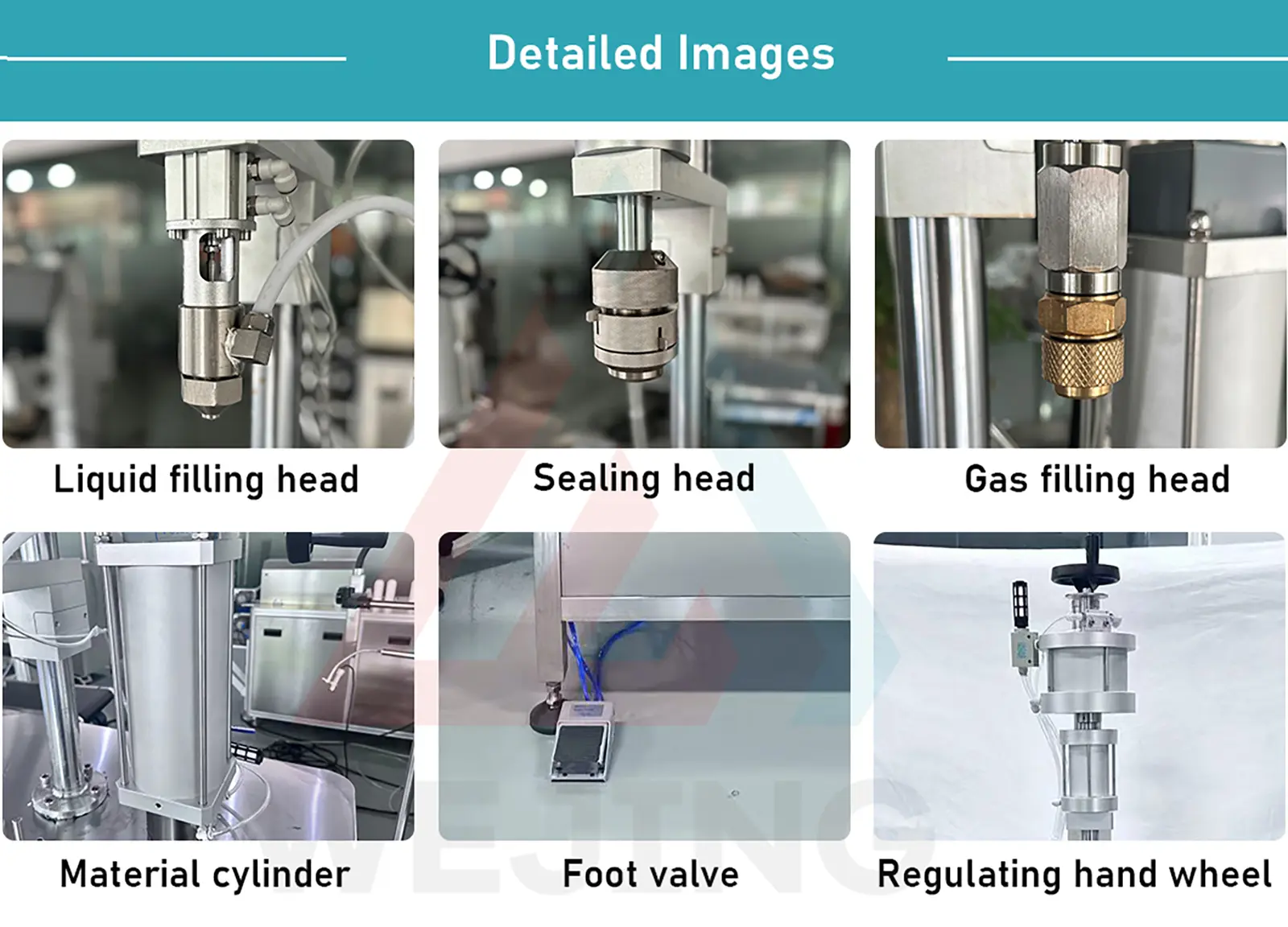

1. Infusion system: composed of a liquid metering cylinder and an infusion head. The liquid measuring cylinder is used to store and measure the liquid material to be filled, while the filling head is responsible for accurately filling the liquid into the aerosol can.

2. Sealing system: including sealing machine and related sealing components. After the liquid filling is completed, seal the aerosol can to ensure that the liquid and gas inside the can do not leak.

3. Inflation system: composed of gas metering cylinder and inflation head. Mainly used to fill propellant gas into aerosol cans, the accuracy and stability of the inflation system have a significant impact on the quality and performance of the product.

4. Tabletop and rack: Provide installation and support for other components of the equipment to ensure its stability and reliability.

5. Pneumatic components: such as cylinders, valves, etc., are the power source and control components of equipment, used to achieve the actions of various systems.

2. Sealing system: including sealing machine and related sealing components. After the liquid filling is completed, seal the aerosol can to ensure that the liquid and gas inside the can do not leak.

3. Inflation system: composed of gas metering cylinder and inflation head. Mainly used to fill propellant gas into aerosol cans, the accuracy and stability of the inflation system have a significant impact on the quality and performance of the product.

4. Tabletop and rack: Provide installation and support for other components of the equipment to ensure its stability and reliability.

5. Pneumatic components: such as cylinders, valves, etc., are the power source and control components of equipment, used to achieve the actions of various systems.

Product Advantages

1. Versatile Operation: Depending on production requirements, it can either operate as a single unit or work in multi - machine linkage, fitting diverse production modes.

2. Precise Filling: The filling and inflation volumes are under accurate control, guaranteeing product quality and uniformity.

3. Broad Applicability: It's applicable for filling various liquid media, even those with certain viscosity and concentration levels.

4. Space - saving Design: With a compact structure, the equipment occupies little space, making it ideal for areas with space constraints.

5. User - friendly Operation: Operators can learn the operation methods after simple training. Moreover, the equipment is relatively easy to maintain.

2. Precise Filling: The filling and inflation volumes are under accurate control, guaranteeing product quality and uniformity.

3. Broad Applicability: It's applicable for filling various liquid media, even those with certain viscosity and concentration levels.

4. Space - saving Design: With a compact structure, the equipment occupies little space, making it ideal for areas with space constraints.

5. User - friendly Operation: Operators can learn the operation methods after simple training. Moreover, the equipment is relatively easy to maintain.

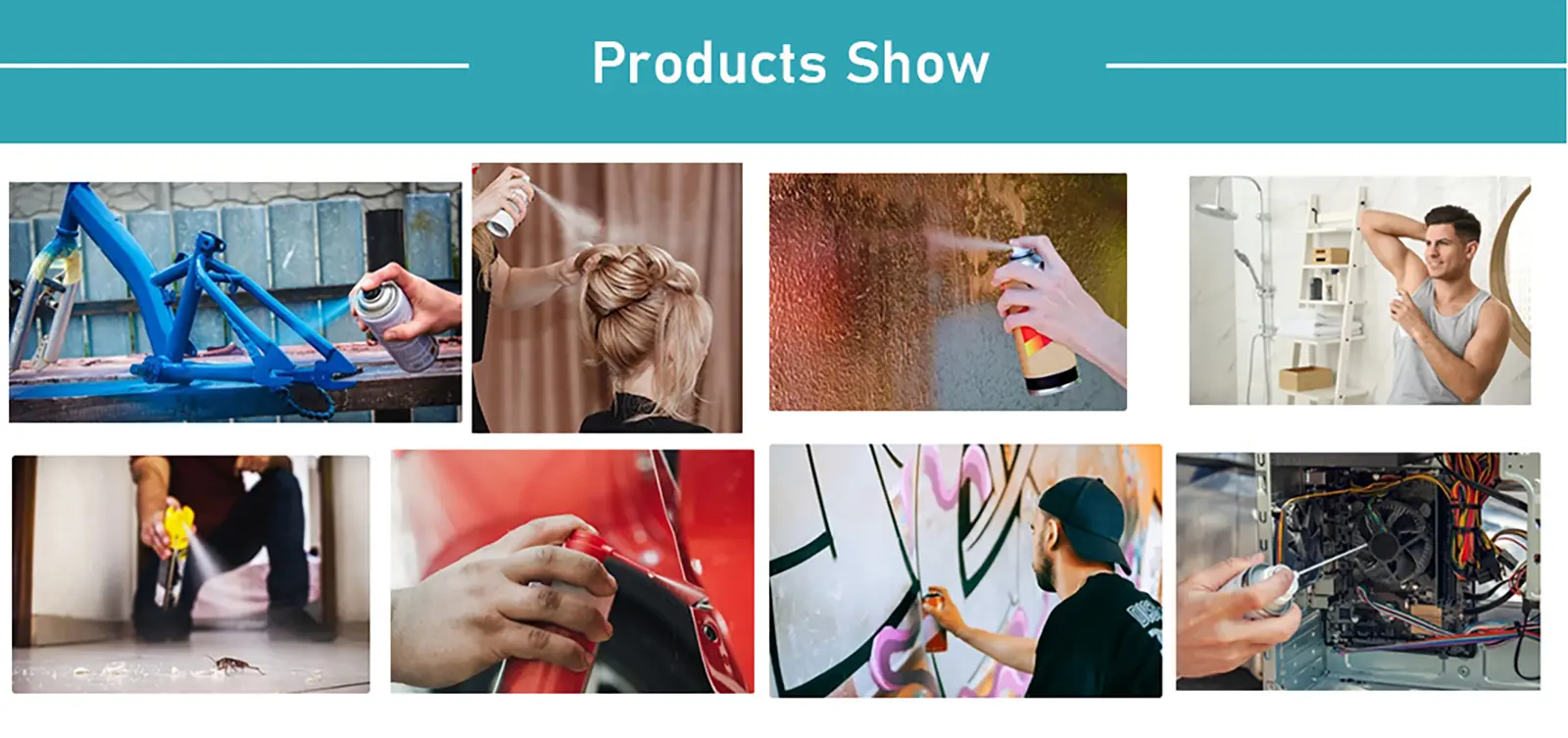

Product Applications

Widely used in industries such as food, medicine, hygiene, automotive, environmental protection, fire protection, and daily chemical products, it is used to produce aerosol products such as mousse, hair gel, air fresheners, insecticides, disinfectants, fire extinguishers, carburetor cleaning agents, etc.