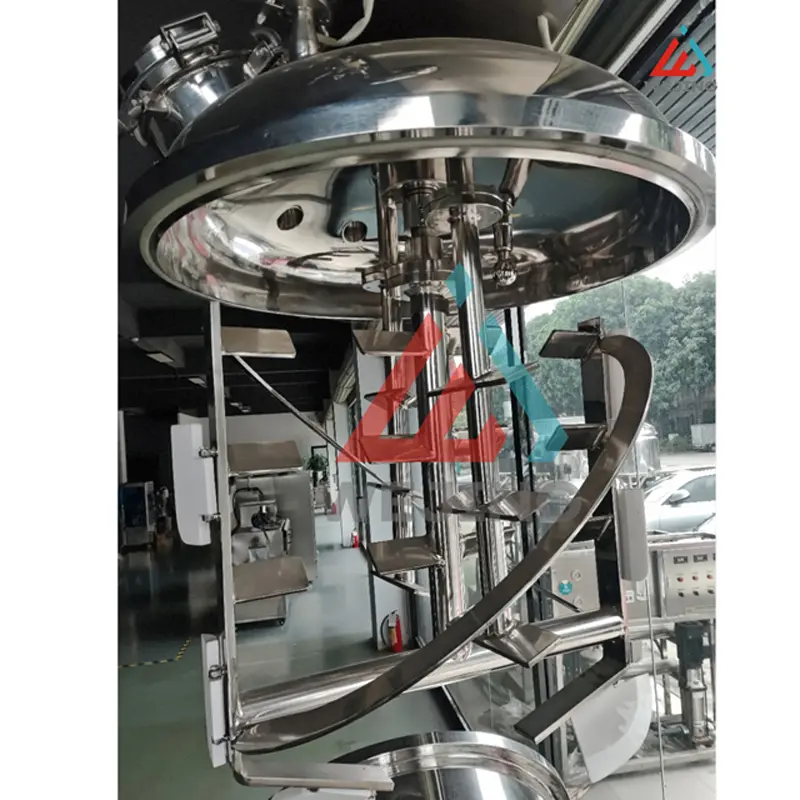

300L Hydraulic Lifting Mixing Equipment

Vacuum Emulsifying MixerPRODUCT PARAMETERS

|

Main pot capacity |

300L |

|

Oil tank capacity |

120L |

|

Pot capacity |

250L |

|

Spiral blade stirring power |

3 kw |

|

Spiral blade stirring speed |

0-63 rpm |

|

Equalizer power |

7.5 kw |

|

Equalizer speed |

0-6000 rpm |

|

Material Science |

Stainless steel 316 304 |

1. First, stir and react the materials, then heat and stir them into a water pot and an oil pot to complete preheating and pre mixing.

2. Then, the material is sucked into the vacuum emulsifier by the vacuum pump. In the vacuum emulsifier, the PTFE scraper always encounters a pot shaped interference body through the stirring center, sweeping away the viscous material hanging on the wall and continuously creating new interfaces for the scraped off material.

3. Then, after being sheared, compressed, and folded, the material enters the homogenizer at the bottom of the pot. Through processes such as shearing, impact, and turbulence, it quickly breaks into small particles between the high-speed rotating cutting disc and the fixed cutting sleeve. Due to the vacuum state of the emulsifier, bubbles generated during the mixing process are promptly expelled, resulting in a smooth and uniform product.

Product Advantages

1. High production efficiency, uniform mixing, and shortened cycle time.

2. The product quality is good, the vacuum is kept clean and stable, and the particles are small.

3. Easy to operate, hydraulic lift, simple switch, intelligent electrical control.

4. Easy to clean, with a reasonable structure that meets hygiene requirements.

2. The product quality is good, the vacuum is kept clean and stable, and the particles are small.

3. Easy to operate, hydraulic lift, simple switch, intelligent electrical control.

4. Easy to clean, with a reasonable structure that meets hygiene requirements.

Product Applications

Hydraulic lift vacuum emulsifiers are widely used in many fields.

- In the cosmetics industry, it can be used to produce lotion, cream, etc.

- In the pharmaceutical industry, ointments, oral fluids, and other products can be produced.

- The food industry can process sauces, juices, etc.

- In the cosmetics industry, it can be used to produce lotion, cream, etc.

- In the pharmaceutical industry, ointments, oral fluids, and other products can be produced.

- The food industry can process sauces, juices, etc.