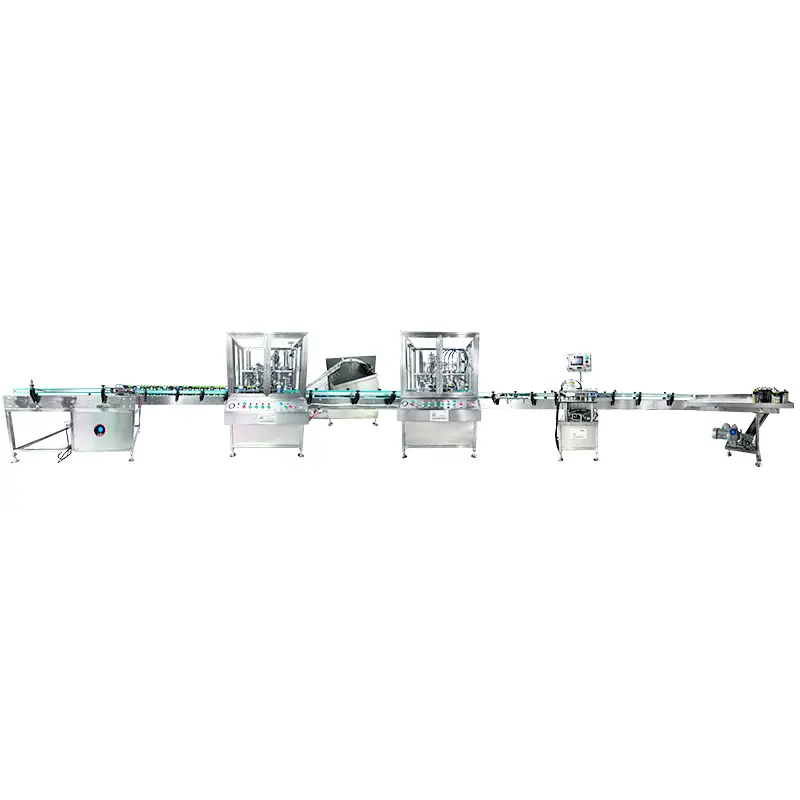

3600 BPH Aerosol Filling Line

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

Liquid Filling Machine

This automatic liquid filling machine is equipped with 4 liquid filling heads. Such a configuration empowers users to concurrently fill materials possessing diverse colors or characteristics, thereby fulfilling a wide range of demands. Additionally, the cleaning process for each filling head is remarkably straightforward. These two standout attributes combine to crown this machine as the premier choice among automatic filling apparatuses.

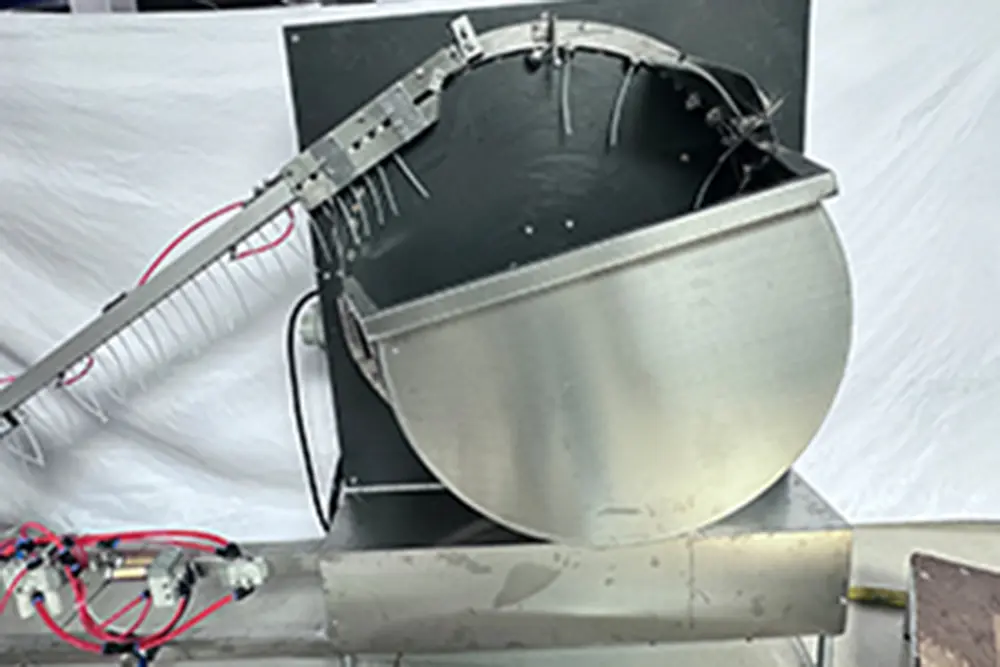

Insert Valve

This Automatic Valve Insert comprises three distinct components. Namely, there is a valve sorting turntable, a valve blowing segment, and a valve placing portion. These elements work in concert to form the cohesive and functional entirety of the Automatic Valve Insert.

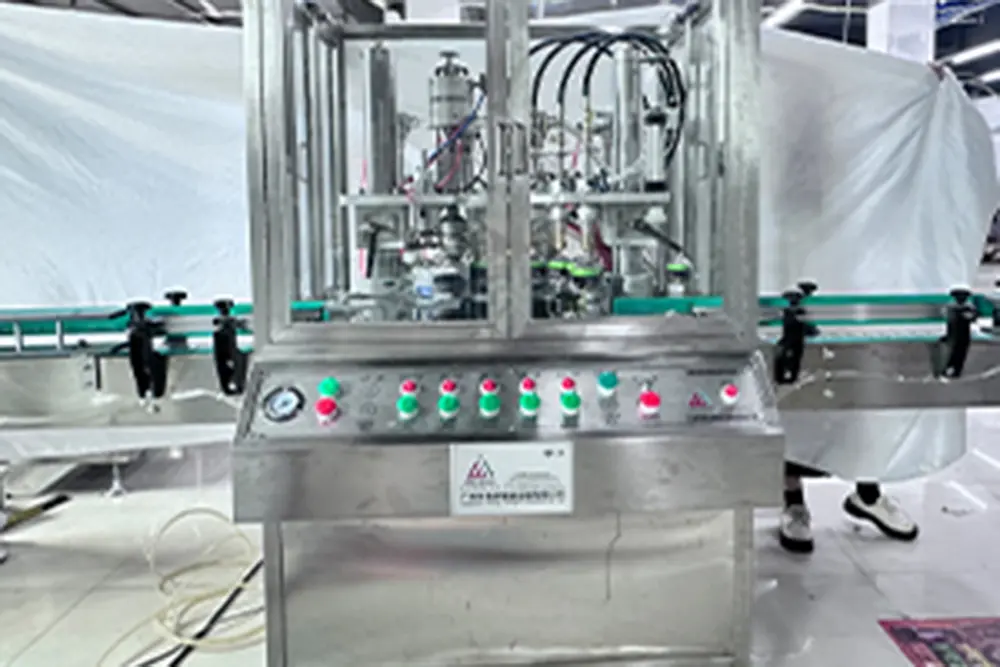

Crimping and Gas Filling Machine

This advanced automatic Aerosol Filling Machine is furnished with four gas filling heads, each strategically positioned on a single workbench. Every individual filling head is under the precise control of its corresponding filling cylinder. The relationship between gas filling volume and filling speed is such that a smaller gas filling volume correlates to a higher filling accuracy. This versatile machine affords users the option to either fill four distinct types of gas simultaneously or focus on filling a single gas variety concurrently.

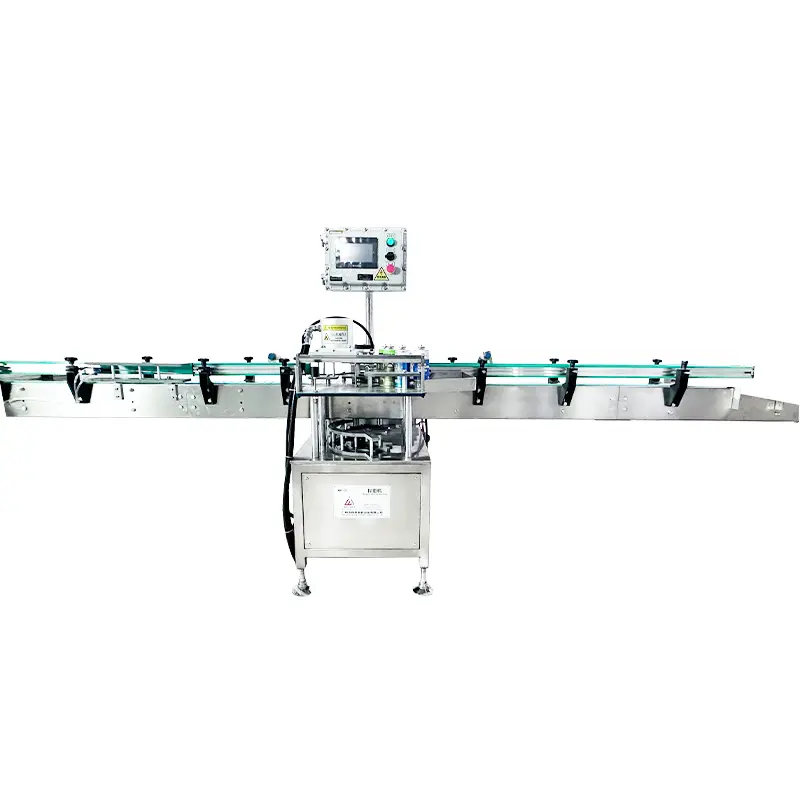

Weight Checking Machine

This High-Speed Automatic Aerosol Weight Check Machine is crafted with a robust and ultra-responsive weighing sensor in conjunction with a signal acquisition apparatus. Its objective is to execute high-speed operational procedures through the utilization of a Programmable Logic Controller (PLC), ensuring efficient and accurate weight verification for aerosol products.

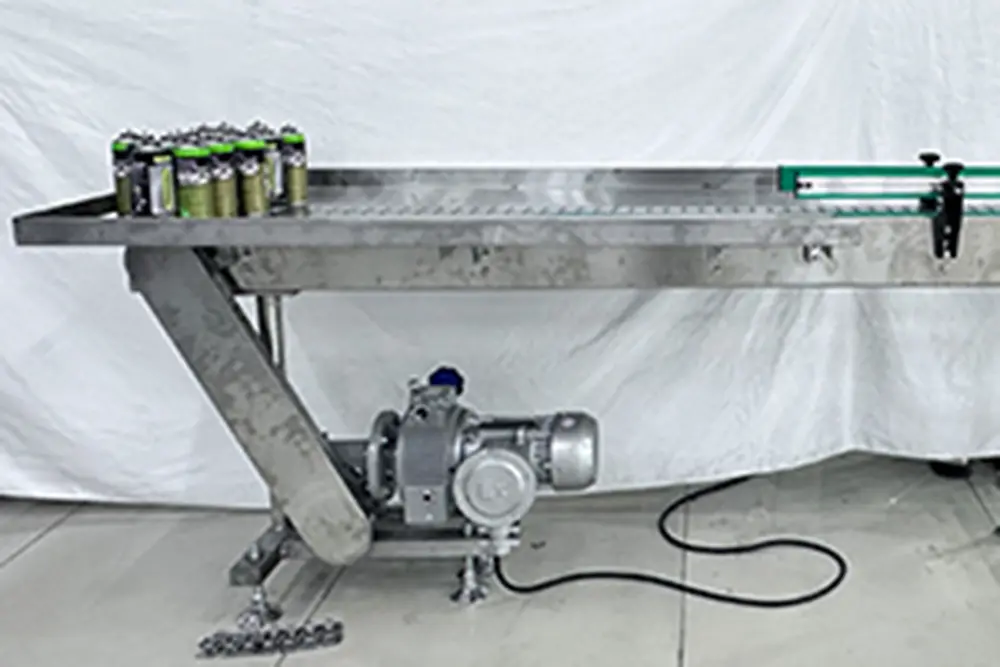

Packing Table

Ideal for fabricating a wide array of aerosol products across multiple sectors, such as the cosmetic domain, pharmaceutical field, household care area, industrial and institutional care realm, and auto care sector.

product FAQ

Why Are Aerosol Filling Machines So Sought After?

Throughout the years, diverse methods have emerged for filling aerosol canisters. The contemporary automated variants have significantly streamlined aerosol production. Thanks to these novel aerosol filling machines, enterprises have managed to satisfy the escalating demand for aerosols. As the technological prowess of this equipment progresses, it will surely assist industries in fulfilling the burgeoning appetite for aerosol products.

What Are the Advantages of Automatic Aerosol Filling Machines?

Employing automated aerosol machines brings forth a host of benefits. When it pertains to filling and packaging aerosol wares, they execute the task with remarkable swiftness. In a brief span, this machinery can churn out a copious quantity of aerosol items. Automatic machines demand less vigilant oversight, translating to reduced effort in maintaining their operation. This apparatus is self-sufficient and doesn't necessitate constant surveillance or manipulation. Consequently, fewer personnel are required at the manufacturing facility. Utilizing an automatic aerosol filling machine augments both efficiency and productivity.

How Are Automated Aerosol Machines Keeping Companies at the Forefront?

Automated aerosol filling machines can satiate the expanding requisites of the aerosol trade. Spray products are gaining enhanced popularity presently and will continue to do so in the forthcoming years, given their user-friendliness and extensive application in daily existence. Moreover, the profusion of chemical products today has spurred a twofold increment in demand.

Aerosol products are also finding utility in the industrial realm and numerous other sectors. Automatic aerosol filling machines are continuously evolving to address these disparate demands. These machines can operate at an exceedingly rapid pace and are promptly accessible whenever the need arises.

In the long haul, it is anticipated that aerosol filling machines will persist in becoming more malleable and proficient, thereby ensuring their continued prevalence and utility in the times ahead.

Throughout the years, diverse methods have emerged for filling aerosol canisters. The contemporary automated variants have significantly streamlined aerosol production. Thanks to these novel aerosol filling machines, enterprises have managed to satisfy the escalating demand for aerosols. As the technological prowess of this equipment progresses, it will surely assist industries in fulfilling the burgeoning appetite for aerosol products.

What Are the Advantages of Automatic Aerosol Filling Machines?

Employing automated aerosol machines brings forth a host of benefits. When it pertains to filling and packaging aerosol wares, they execute the task with remarkable swiftness. In a brief span, this machinery can churn out a copious quantity of aerosol items. Automatic machines demand less vigilant oversight, translating to reduced effort in maintaining their operation. This apparatus is self-sufficient and doesn't necessitate constant surveillance or manipulation. Consequently, fewer personnel are required at the manufacturing facility. Utilizing an automatic aerosol filling machine augments both efficiency and productivity.

How Are Automated Aerosol Machines Keeping Companies at the Forefront?

Automated aerosol filling machines can satiate the expanding requisites of the aerosol trade. Spray products are gaining enhanced popularity presently and will continue to do so in the forthcoming years, given their user-friendliness and extensive application in daily existence. Moreover, the profusion of chemical products today has spurred a twofold increment in demand.

Aerosol products are also finding utility in the industrial realm and numerous other sectors. Automatic aerosol filling machines are continuously evolving to address these disparate demands. These machines can operate at an exceedingly rapid pace and are promptly accessible whenever the need arises.

In the long haul, it is anticipated that aerosol filling machines will persist in becoming more malleable and proficient, thereby ensuring their continued prevalence and utility in the times ahead.