3600 BPH Automatic Aerosol Filling Machine

Enhanced Productivity

Automated aerosol fillers work faster, enhancing output. Manual may fill 600 cans/hr; automatic can fill 3600+. Greater efficiency means more products in less time.

Precise Filling

State-of-the-art automation in these machines enables exact fill amounts. In perfume production, each canister gets precisely 500ml, maintaining quality and brand image.

Optimal Labor Use

Automation cuts labor needs. A factory might need only 10 workers instead of 50 for filling. The rest can focus on crucial tasks like quality checks and maintenance.

Safer Operations

These machines isolate hazards. When handling flammable substances, the design shields operators, meeting strict safety norms and reducing risks.

Adaptable System

Automatic aerosol fillers handle diverse can sizes and products. A company can switch between small and large cans easily. New product demands? The system quickly adapts, staying competitive.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

40-50 |

|

Liquid filling volume (ml) |

10-600( can be customized) |

|

Gas filling volume (ml) |

10-600( can be customized) |

|

Filling heads |

2 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

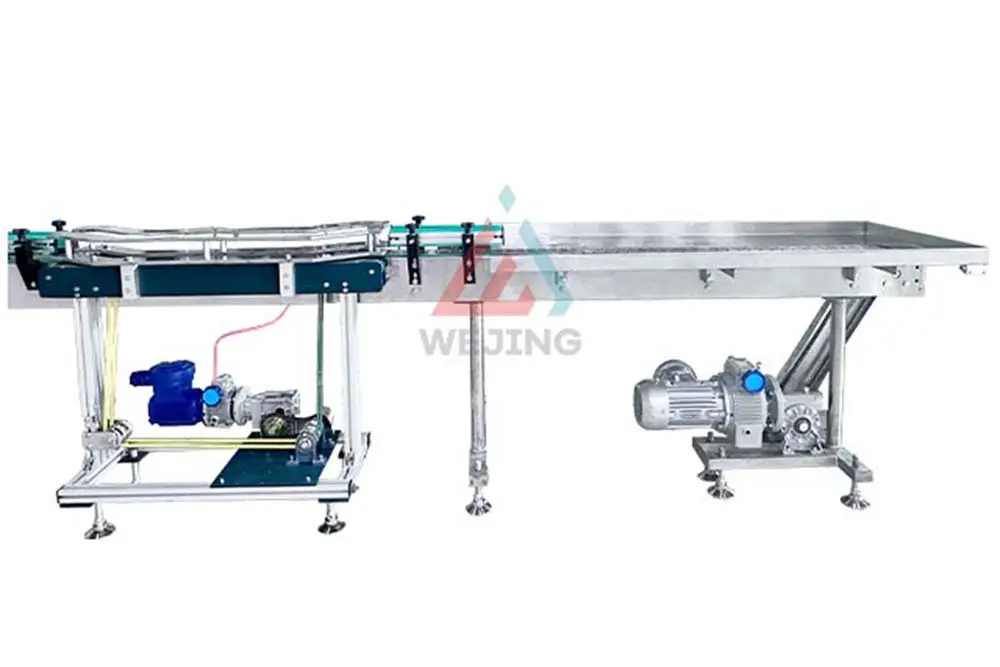

Auto Can Feeding Machine

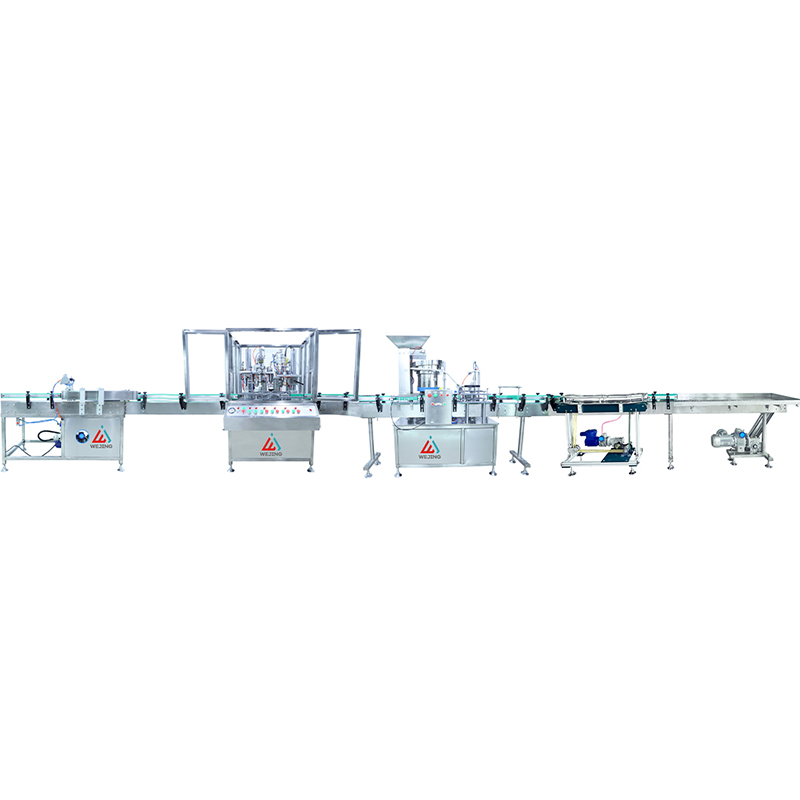

It is capable of ensuring the smooth operation of bottles within the production line. It exhibits high levels of efficiency and leads to a diminished labor burden.Aerosol Filling Sealing Production Line

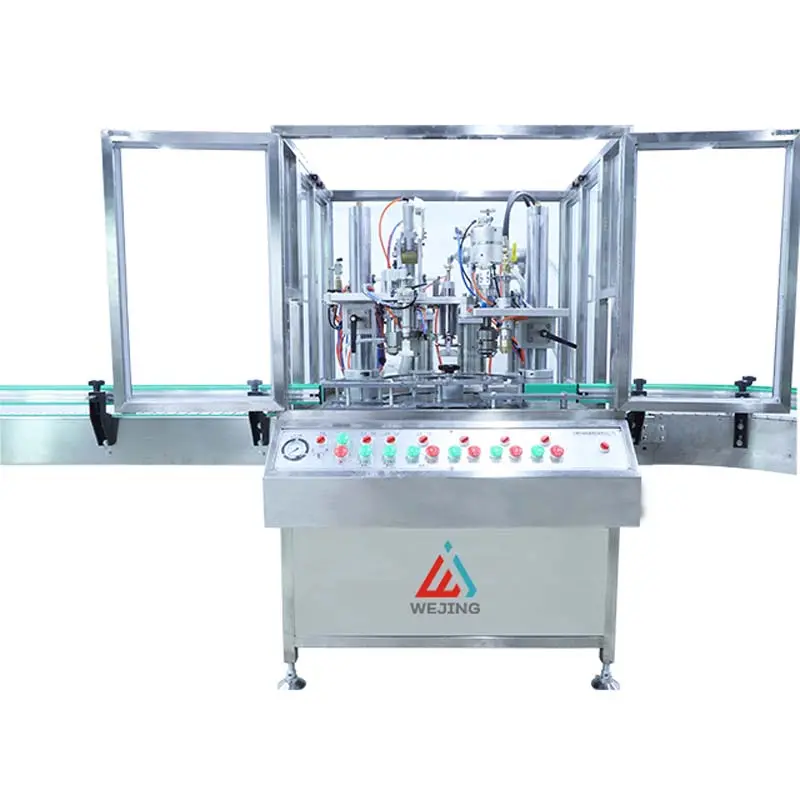

The QGJ70 Automatic aerosol filling production line is constructed from a rotary table that features a liquid filling head, an insert valve, a crimping head, and a gas filling head, along with a compressed air piston pump and a conveyor belt among other components.

Auto Actuator Fixed Machine

The Auto actuator fixed machine is utilized for the mounting of spray actuators on aerosol products.

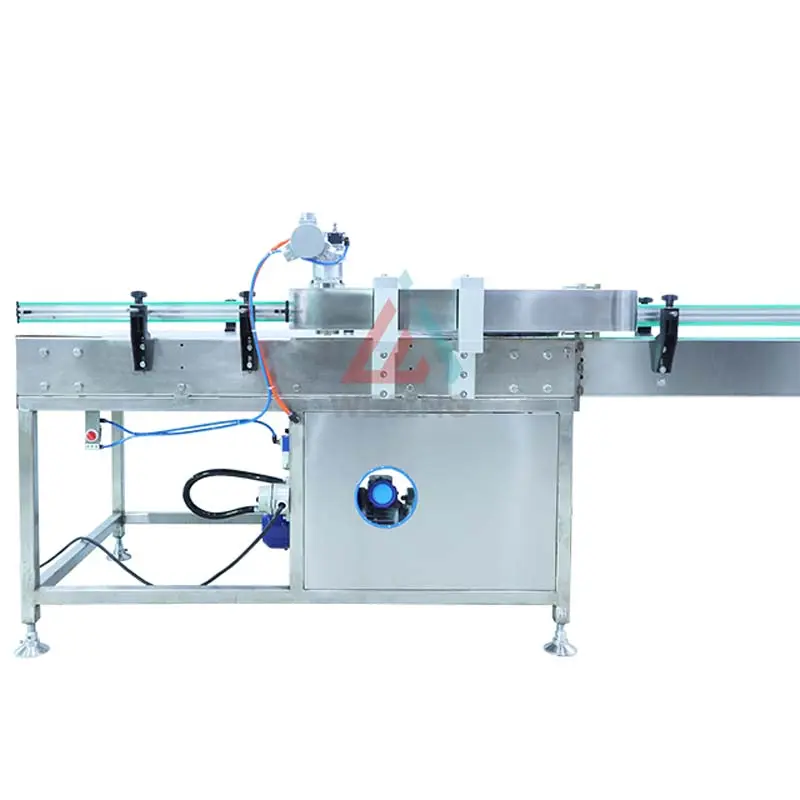

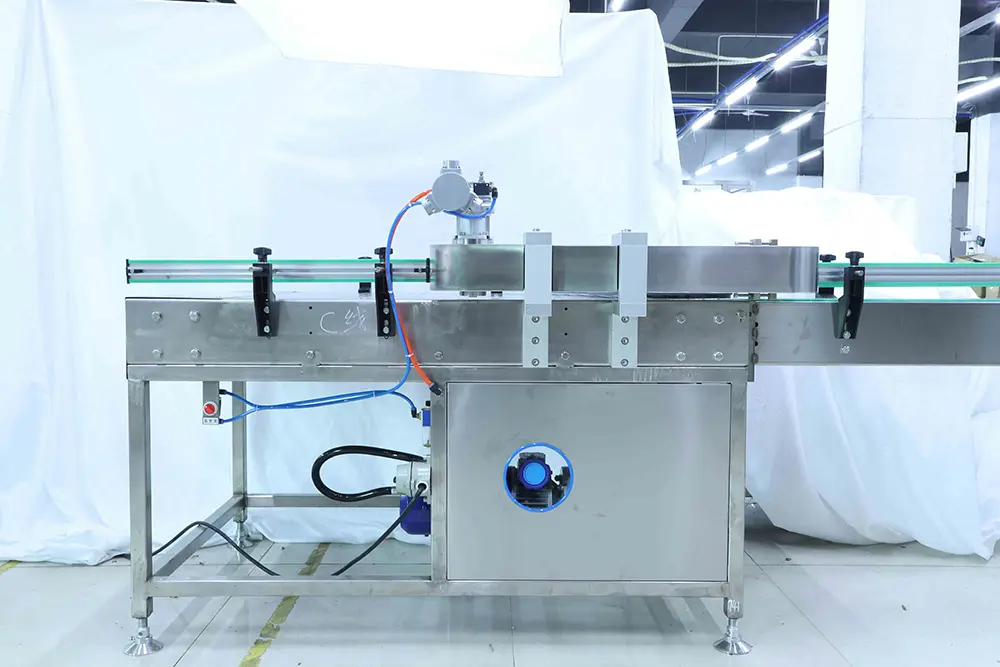

Inkjet Belt and Convayor Table

The Inkjet belt makes use of an imported conveyor. The aerosol cans are propelled by explosion-proof motors into the track for spraying.

Operate Guide

- Examine all machine components to identify any potential damage and confirm proper connections.

- Ascertain that an adequate supply of raw materials and lubricants is available.

- Validate the accuracy of the settings configured on the control panel.

2. Operational Phase

- Monitor the machine's indicator lights vigilantly to detect any signs of malfunction.

- Routinely conduct quality checks on filled aerosol cans.

3. Safety Regulations

- Adhere stringently to established safety protocols.

- Refrain from inserting hands or objects into the machine during its operation.

4. Maintenance Guidelines

- Thoroughly clean the machine following each use.

- Periodically inspect and replace deteriorated parts.

- Maintain a neat and orderly work environment in the vicinity of the machine.

5. Shutdown Sequence

- Activate the stop button located on the control panel.

- Disconnect the power source.

product FAQ

The machine has a high filling accuracy, typically within ±0.5% to ±1%, ensuring precise filling for each aerosol can.

2: Can it handle different can sizes?

Yes, it can be adjusted to work with various standard aerosol can sizes by modifying parts like star wheel molds.

3: What safety features does it have?

It has safety interlocks, explosion-proof motors, emergency stop buttons, and sensors to monitor pressure and temperature.

4: How easy is maintenance?

Maintenance is straightforward. Regular cleaning, easy access to parts for inspection and replacement, and a provided schedule help keep it in good condition.

5: What propellants can it fill?

It can fill common propellants like DME, LPG, R134a, N2, and CO2, calibrated for their specific properties.