4 in 1 Aerosol Filling Crimping Machine

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Capacity |

600-1200 cans/ hour, depending on filing volume |

|

Liquid filling capacity |

30-500ml(can be adjustable) |

|

Gas filling capacity |

30-500ml(can be adjustable) |

|

Filling accuracy |

≤±1% |

|

Applicable aerosol can diameter |

40-70mm |

|

Suitable aerosol can height |

70-300mm |

|

Air source |

0.5-0.6Mpa |

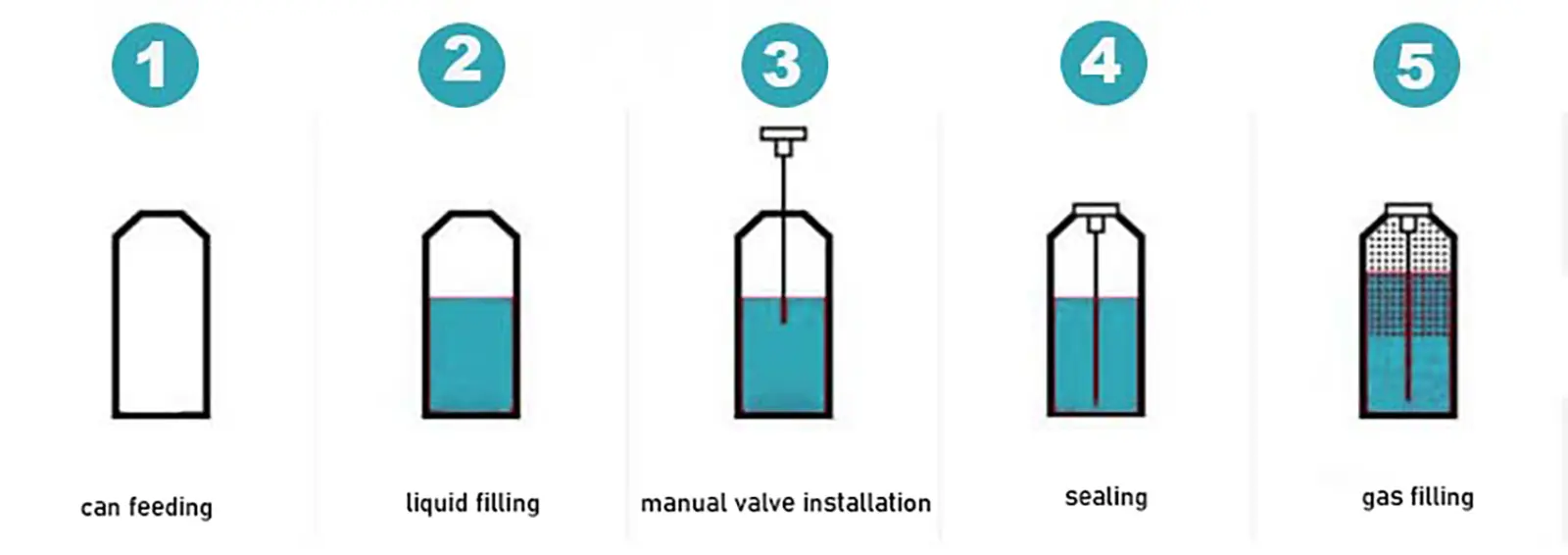

Automatic Bag On Valve Aerosol Filling MachineWorking Process

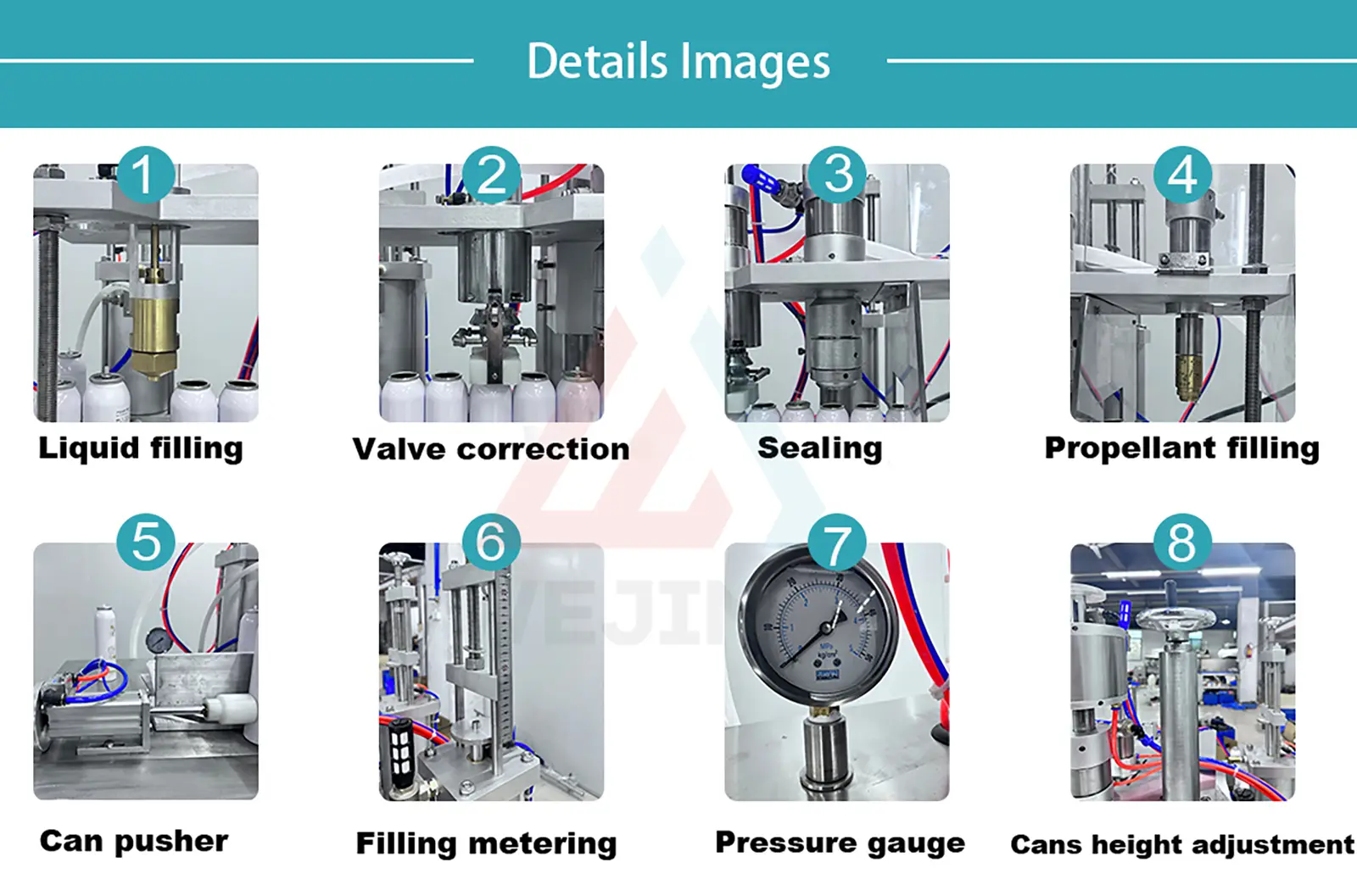

1. Bottle Feeding: The single - item product containers are neatly delivered to the work area by a conveyor system, ensuring an orderly supply for the subsequent operations.

2. Liquid Filling: Through the pipeline and filling head, materials are poured from the storage tank into the bottles. A measuring device is employed to ensure precise filling. The filling speed can be adjusted, which helps to boost the overall production efficiency.

3. Manual Valve Release: This operation demands that the operator has a particular level of expertise. Only with sufficient proficiency can the subsequent processes proceed smoothly.

4. Curling Sealing: By using squeezing or other relevant techniques, the mouths of the bottles are sealed tightly. This guarantees the integrity and safety of the product within.

5.Inflation: Specific gases are filled based on the product's requirements. The quantity and pressure of the inflation are strictly controlled to ensure the product's performance and safety are both maintained at a high level.

2. Liquid Filling: Through the pipeline and filling head, materials are poured from the storage tank into the bottles. A measuring device is employed to ensure precise filling. The filling speed can be adjusted, which helps to boost the overall production efficiency.

3. Manual Valve Release: This operation demands that the operator has a particular level of expertise. Only with sufficient proficiency can the subsequent processes proceed smoothly.

4. Curling Sealing: By using squeezing or other relevant techniques, the mouths of the bottles are sealed tightly. This guarantees the integrity and safety of the product within.

5.Inflation: Specific gases are filled based on the product's requirements. The quantity and pressure of the inflation are strictly controlled to ensure the product's performance and safety are both maintained at a high level.

Product Advantages

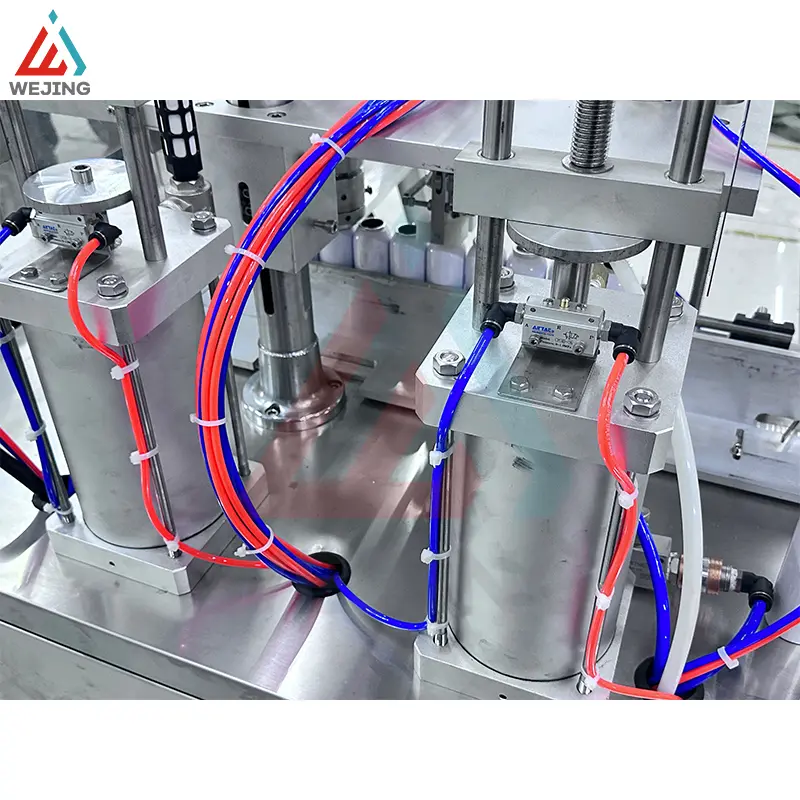

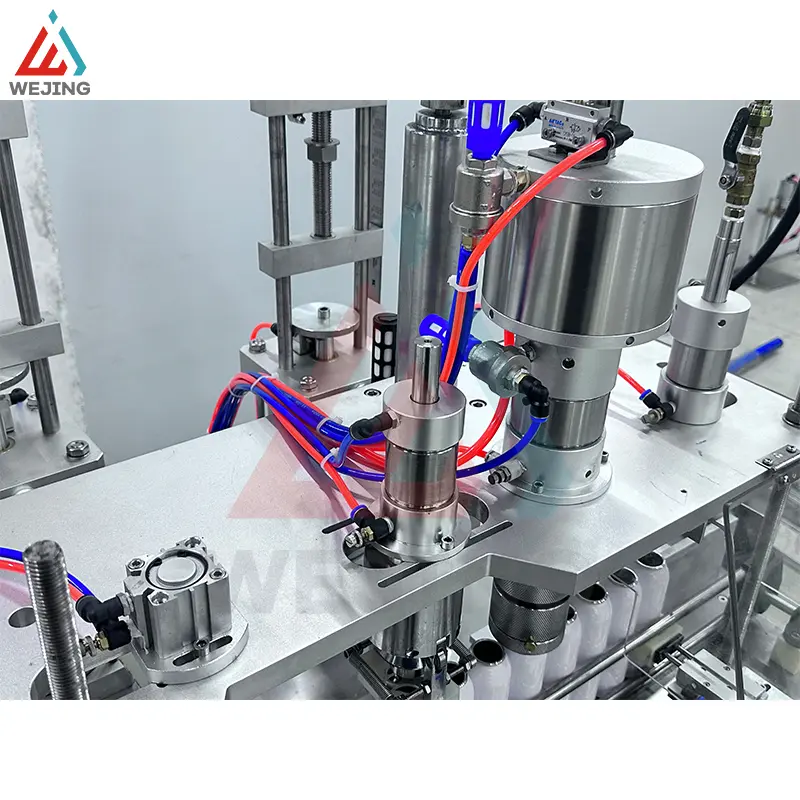

1. By combining liquid filling, valve alignment, sealing, and gas filling functions into a single entity, it achieves highly efficient integration. This not only creates space - saving advantages but also leads to cost reduction.

2. The machine has the capability to control the filling volume of liquids and gases with great accuracy. As a result, it ensures that the quality of the product is stable and reliable throughout the production process.

3. Its reliable sealing technology is highly effective in preventing any leakage. Meanwhile, the valve straightening device it features can precisely ensure the correct positioning of the valve, leaving no room for errors.

4. The semi - automatic operation mode is a great advantage. It not only enhances the overall work efficiency but also makes the process of making adjustments during operation extremely convenient.

5. This device finds extensive application in a wide range of fields, including the daily chemical, pharmaceutical, and industrial industries. It is versatile enough to meet the diverse demands of different production scenarios.

6. The structure of the equipment is well - designed and reasonable. This makes it very easy to conduct maintenance work, saving both time and effort.

7. Made from durable materials, the equipment has an extended service life. Additionally, the operation manual provided is extremely helpful for carrying out daily maintenance tasks, making it user - friendly.

2. The machine has the capability to control the filling volume of liquids and gases with great accuracy. As a result, it ensures that the quality of the product is stable and reliable throughout the production process.

3. Its reliable sealing technology is highly effective in preventing any leakage. Meanwhile, the valve straightening device it features can precisely ensure the correct positioning of the valve, leaving no room for errors.

4. The semi - automatic operation mode is a great advantage. It not only enhances the overall work efficiency but also makes the process of making adjustments during operation extremely convenient.

5. This device finds extensive application in a wide range of fields, including the daily chemical, pharmaceutical, and industrial industries. It is versatile enough to meet the diverse demands of different production scenarios.

6. The structure of the equipment is well - designed and reasonable. This makes it very easy to conduct maintenance work, saving both time and effort.

7. Made from durable materials, the equipment has an extended service life. Additionally, the operation manual provided is extremely helpful for carrying out daily maintenance tasks, making it user - friendly.

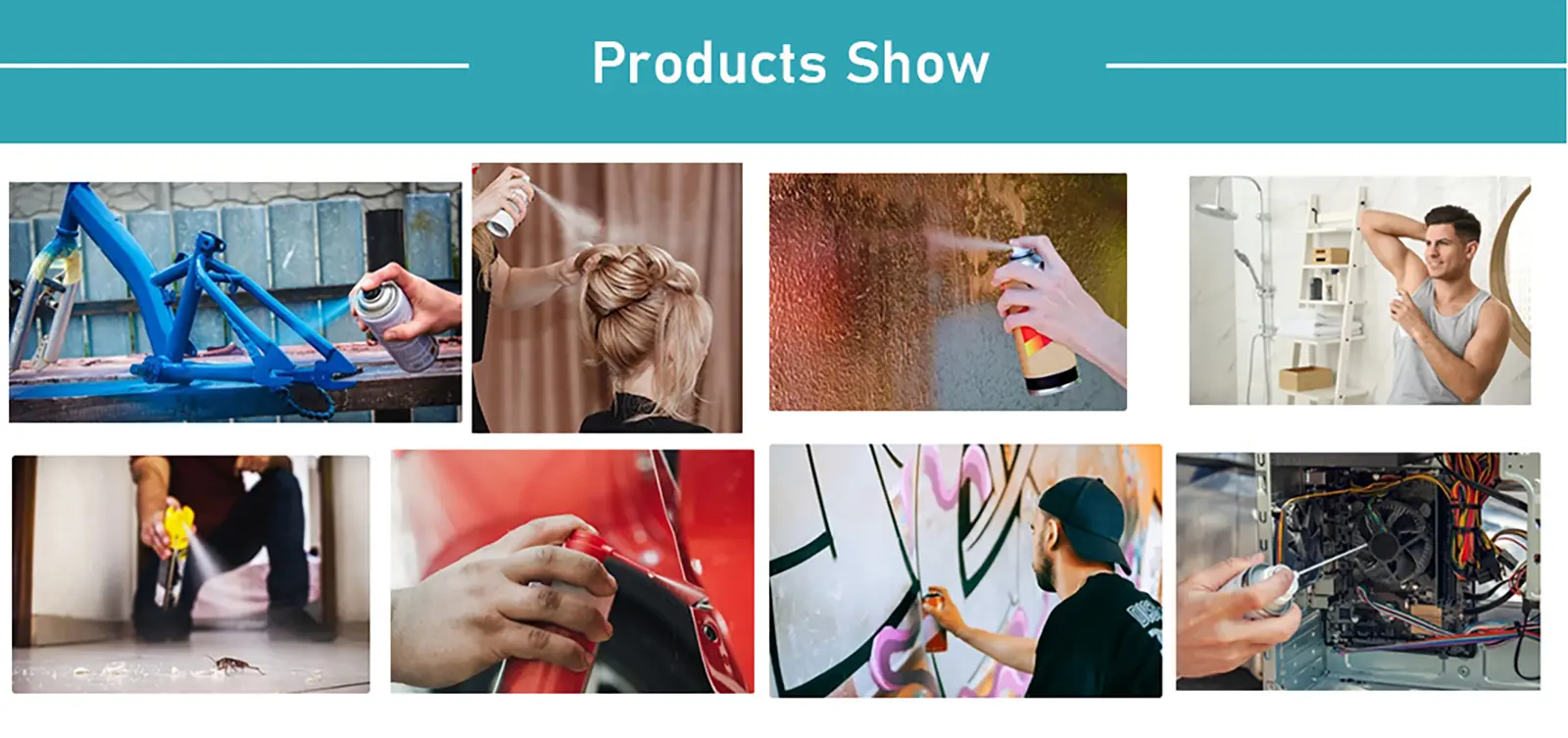

PRODUCT Applications

Semi - automatic aerosol is well - suited for aerosol products within multiple fields, including industrial building materials, cosmetics, automotive care, the pharmaceutical sector, daily - chemical household items, and the food industry.