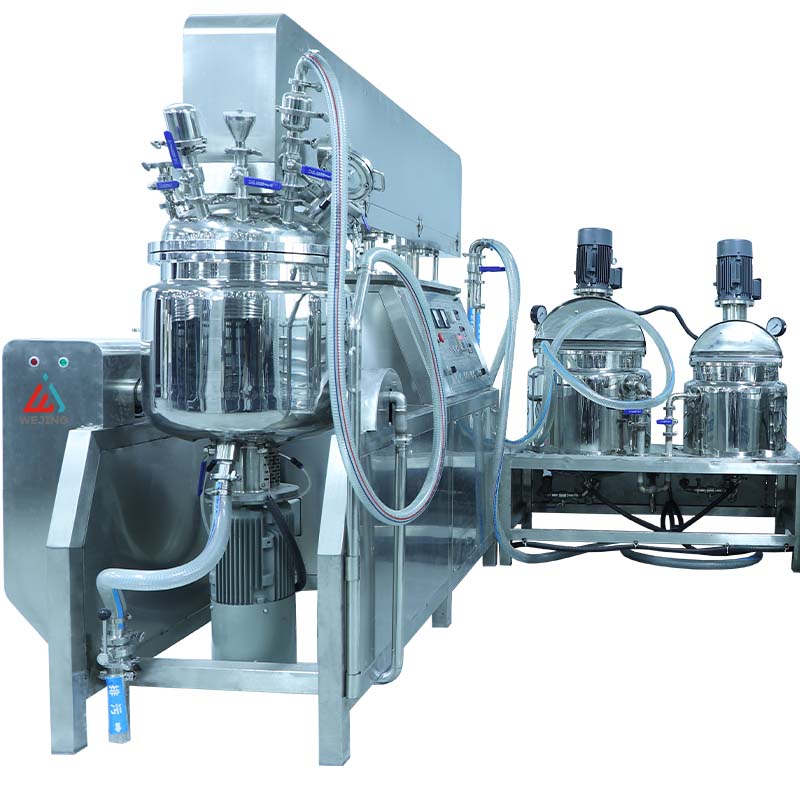

50L High Shear Mixer Equipment

Vacuum Emulsifying MixerPRODUCT PARAMETERS

|

Model |

Capacity(L) |

Mixing |

Homogenizing |

||

|

Power(kw) |

Speed(r/min) |

Power(kw) |

Speed(r/min) |

||

|

WJ-LBD10 |

10 |

0.37 |

0-63 |

1.5 |

0-3000 |

|

WJ-LBD50 |

50 |

0.75 |

0-63 |

3 |

0-3000 |

|

WJ-LBD100 |

100 |

1.5 |

0-63 |

4 |

0-3000 |

|

WJ-LBD200 |

200 |

2.2 |

0-63 |

5.5 |

0-3000 |

|

WJ-LBD300 |

300 |

3 |

0-63 |

7.5 |

0-3000 |

|

WJ-LBD500 |

500 |

4 |

0-63 |

11 |

0-3000 |

Product Features

1.Generous Capacity and Exquisite Engineering:

Boasting a 50L capacity, it suits medium-scale production demands. It is precisely engineered, employing premium materials that are not only long-lasting but also resistant to wear and corrosion. This extends its operational life and curtails maintenance requirements.

2.Exceptional Emulsification and Blending:

The high-shear homogenizer functionality ensures outstanding emulsification, yielding uniform and stable mixtures of liquid soap and cosmetic components. It harnesses vacuum homogenization technology for thorough material mixing, resulting in evenly dispersed end products and enhanced product uniformity.

3.Sophisticated Control Mechanisms:

It is equipped with an advanced control system for effortless operation. Parameters such as speed and temperature can be fine-tuned accurately, guaranteeing consistent product quality and reproducibility.

Product Applications

1.Pharmaceutical Field: Used for homogenizing and heating liquid medicines, preparing ointments and creams, and conducting pill coating and granulation procedures.

2.Cosmetics Sector: In this area, it homogenizes and heats lotions and creams, prepares serums and essences, and emulsifies makeup products.

3.Chemical Industry: Paints and coatings are homogenized and heated, adhesives and sealants are prepared, and chemical raw materials are mixed.

4.Toiletries: Shampoos and conditioners are homogenized and heated, body washes and shower gels are prepared, and toothpastes and mouthwashes are mixed.

5.Food Industry: Sauces and dressings are homogenized and heated, jams and spreads are prepared, and beverages and dairy products are emulsified.

6.Agriculture: Pesticides and herbicides are homogenized and heated, fertilizers and soil amendments are prepared, and animal feed supplements are emulsified.

7.Personal Care: Hair care products are homogenized and heated, skin care creams and lotions are prepared, and essential oils and fragrances are mixed.

2.Cosmetics Sector: In this area, it homogenizes and heats lotions and creams, prepares serums and essences, and emulsifies makeup products.

3.Chemical Industry: Paints and coatings are homogenized and heated, adhesives and sealants are prepared, and chemical raw materials are mixed.

4.Toiletries: Shampoos and conditioners are homogenized and heated, body washes and shower gels are prepared, and toothpastes and mouthwashes are mixed.

5.Food Industry: Sauces and dressings are homogenized and heated, jams and spreads are prepared, and beverages and dairy products are emulsified.

6.Agriculture: Pesticides and herbicides are homogenized and heated, fertilizers and soil amendments are prepared, and animal feed supplements are emulsified.

7.Personal Care: Hair care products are homogenized and heated, skin care creams and lotions are prepared, and essential oils and fragrances are mixed.