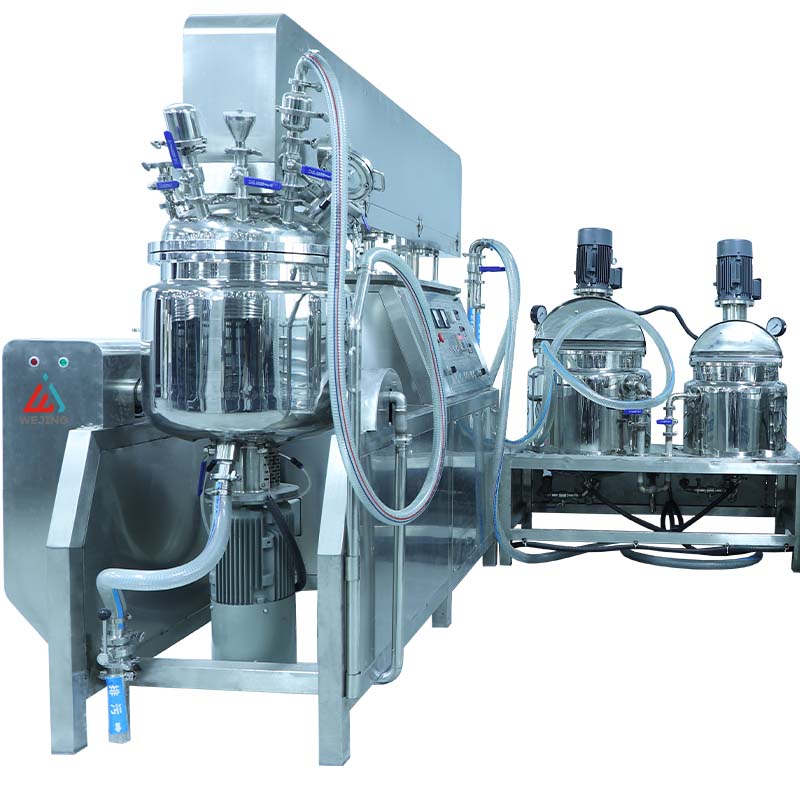

50L Vacuum Mixer Equipment

Vacuum Emulsifying MixerPRODUCT PARAMETERS

|

Model |

Capacity(L) |

Mixing |

Homogenizing |

||

|

Power(kw) |

Speed(r/min) |

Power(kw) |

Speed(r/min) |

||

|

WJ-M50 |

50 |

0.55 |

0-60 |

1.5 |

0-3000 |

|

WJ-M100 |

100 |

0.75 |

0-60 |

1.5 |

0-3000 |

|

WJ-M200 |

200 |

1.5 |

0-60 |

3 |

0-3000 |

|

WJ-M300 |

300 |

2.2 |

0-60 |

4 |

0-3000 |

|

WJ-M500 |

500 |

2.2 |

0-60 |

5.5 |

0-3000 |

|

WJ-M1000 |

1000 |

4 |

0-60 |

11 |

0-3000 |

|

WJ-M2000 |

2000 |

5.5 |

0-60 |

15 |

0-3000 |

Working Principle

The 50L Vacuum Homogenization Emulsifier Mixer is mainly composed of a pretreatment pot, an emulsification stirring pot, a lifting system, a vacuum system, an electrical control system and other parts. Its working principle is as follows:

After the materials are heated and stirred and mixed in the water and oil pans, they are sucked into the emulsification pot by a vacuum pump. In the emulsification pot, the materials are always stirred against the pot shape by the stirring paddle and polytetrafluoroethylene scraper in the homogenization pot, sweeping away the wall-hanging sticky materials, so that the scraped materials continuously generate new interfaces. After a series of processes such as shearing, compression, and folding by the stirring blade, the materials are quickly broken into particles of 200μm to 2μm. Since the emulsification pot is in a vacuum state, the bubbles generated by the materials during the stirring process are extracted in time, thereby obtaining a bubble-free, delicate and stable product.

After the materials are heated and stirred and mixed in the water and oil pans, they are sucked into the emulsification pot by a vacuum pump. In the emulsification pot, the materials are always stirred against the pot shape by the stirring paddle and polytetrafluoroethylene scraper in the homogenization pot, sweeping away the wall-hanging sticky materials, so that the scraped materials continuously generate new interfaces. After a series of processes such as shearing, compression, and folding by the stirring blade, the materials are quickly broken into particles of 200μm to 2μm. Since the emulsification pot is in a vacuum state, the bubbles generated by the materials during the stirring process are extracted in time, thereby obtaining a bubble-free, delicate and stable product.

Product FAQ

Q: Is the operation difficult?

A: No. It has an intelligent control system with a simple interface. After brief training, operators can handle it easily.

Q: Is maintenance troublesome?

A: No. Just clean and check key parts regularly. Such as stirrer and seals. Low cost and short time-consuming.

Q: Does it ensure stable product quality?

A: Yes. Vacuum homogenization avoids bubbles. Precise control of parameters ensures consistent quality.

Q: How about its capacity?

A: 50L capacity is suitable for medium-scale production. Can meet the needs of different industries.

Q: Is it energy-efficient?

A: Yes. Optimized design reduces energy consumption. While ensuring high-performance operation.

A: No. It has an intelligent control system with a simple interface. After brief training, operators can handle it easily.

Q: Is maintenance troublesome?

A: No. Just clean and check key parts regularly. Such as stirrer and seals. Low cost and short time-consuming.

Q: Does it ensure stable product quality?

A: Yes. Vacuum homogenization avoids bubbles. Precise control of parameters ensures consistent quality.

Q: How about its capacity?

A: 50L capacity is suitable for medium-scale production. Can meet the needs of different industries.

Q: Is it energy-efficient?

A: Yes. Optimized design reduces energy consumption. While ensuring high-performance operation.