7200 BPH Aerosol Filling Machine

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

90-120 cans/min |

|

Filling volume (ml) |

30-1200ml |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 350( can be customized) |

|

Applicable valve (mm) |

1 inch ( can be customized) |

|

Working pressure (Mpa) |

0.6 - 1 |

|

Max gas consumption (m3/min) |

6.4 |

|

Power (KW) |

45 |

|

Dimension (LWH) mm |

30500*4800*2550 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

Can Feeding Machine

Make sure the cans are placed properly and in an orderly manner on the conveyor belt for continuous feeding.

Filling Sealing Machine

It is composed of rotary tabe eight or ten heads liquid flling head and gas filling head.With valveinserting mechanism and pressingvalvemechanism. feeding.

Weight Checking Machine

It's utilized for the online weighing inspection of every single can within the aerosol production line.ding.

Auto Actuator Fixed Machine

It is employed for the installation of spray actuators in aerosol produc

Auto Capping Machine

It's utilized for packaging the outer plastic caps of aerosol products.Product Applications

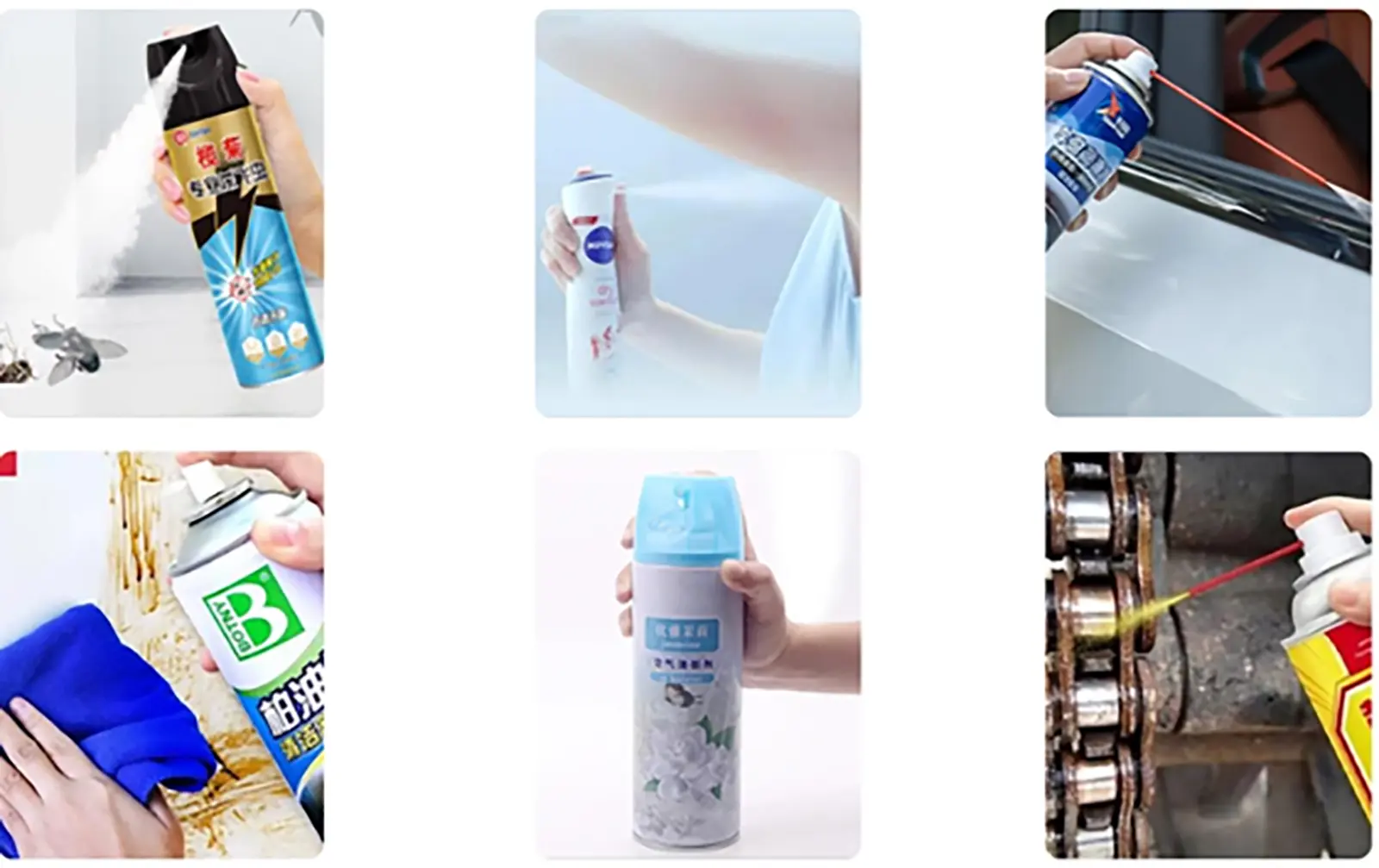

1. Personal Care Sector: High - speed aerosol filling equipment is of great significance in producing personal care products. This includes deodorants, hair styling sprays, body fragrances, shaving foams and different aerosol cosmetic formulas. It provides efficient and hygienic packaging solutions.

2. Home and Cleaning Product Production: These machines are extremely valuable in putting together and packaging household cleaning products. Such products are air purifiers, insect repellents, disinfecting aerosols, wood polishes and oven cleaners. This ensures large - scale production and consistent high - quality products.

Pharmaceutical and Medical Applications: In the pharmaceutical field, high - speed aerosol filling processes are essential for making metered - dose inhalers, topical treatments and sanitizing sprays. These require precise dose control and strict adherence to tough industry regulations

2. Home and Cleaning Product Production: These machines are extremely valuable in putting together and packaging household cleaning products. Such products are air purifiers, insect repellents, disinfecting aerosols, wood polishes and oven cleaners. This ensures large - scale production and consistent high - quality products.

Pharmaceutical and Medical Applications: In the pharmaceutical field, high - speed aerosol filling processes are essential for making metered - dose inhalers, topical treatments and sanitizing sprays. These require precise dose control and strict adherence to tough industry regulations

Product FAQ

1. What kind of propellants can it work with?

It's compatible with common propellants used in insecticide sprays as long as they meet safety and performance requirements.

2. Does the machine have an automatic cleaning function?

Yes, it has an automatic cleaning cycle to maintain hygiene and prevent cross - contamination.

3. How long is the warranty period?

The standard warranty is usually one year, covering manufacturing defects.

4. Can it fill cans with multiple - layer coatings?

Yes, it can handle cans with various types of coatings without affecting the filling process.

5. Is there an alarm system in case of malfunctions?

Yes, there's an alarm system that alerts operators of any malfunctions during the filling process.

It's compatible with common propellants used in insecticide sprays as long as they meet safety and performance requirements.

2. Does the machine have an automatic cleaning function?

Yes, it has an automatic cleaning cycle to maintain hygiene and prevent cross - contamination.

3. How long is the warranty period?

The standard warranty is usually one year, covering manufacturing defects.

4. Can it fill cans with multiple - layer coatings?

Yes, it can handle cans with various types of coatings without affecting the filling process.

5. Is there an alarm system in case of malfunctions?

Yes, there's an alarm system that alerts operators of any malfunctions during the filling process.