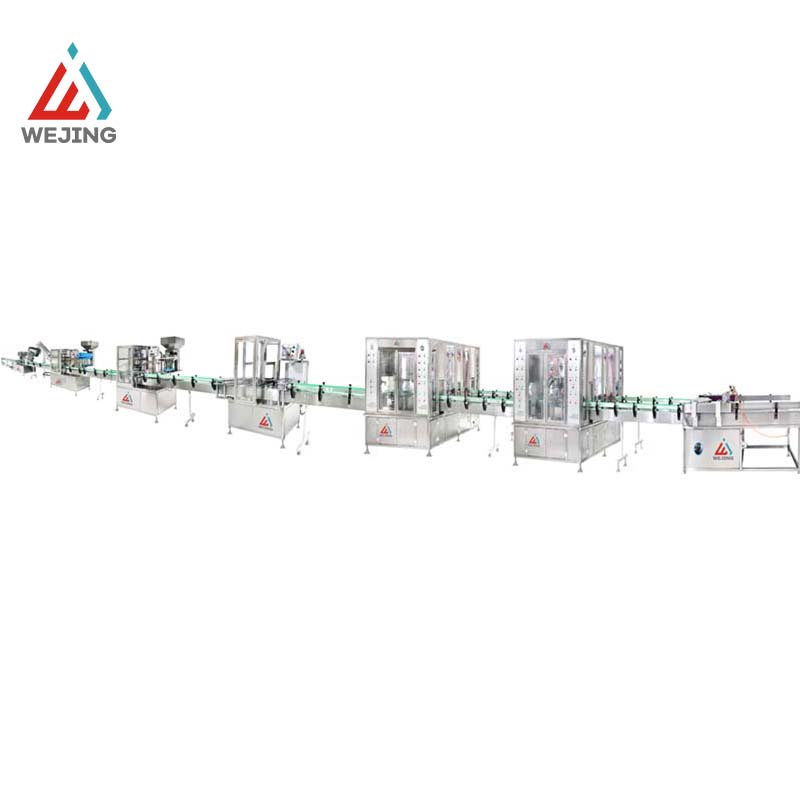

9000 BPH Aerosol Filling Machine

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Voltage |

380V/50HZ( can be customized ) |

|

Dimension(L*W*H) |

22000*4000*2000mm |

|

Production speed |

130-150 cans/min |

|

Propellant Type |

The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

|

Noise control |

≤80 dB |

|

Can Type |

Tinplate can or aluminum can |

|

Driven Type |

Pneumatic control |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

|

Filling accuracy |

≤±1% |

Can Feeding Machine

Full pneumatic components guarantee safety.

It provides necessary equipment as well as optional additional parts.

It's perfect for clients who are involved in large - scale aerosol product production.

Filling Crimping Machine

The main pneumatic element and seal ring are of international - quality products, thus having outstanding reliability and abrasion resistance.

The conveyor of the production line uses an explosion - proof variable - speed motor, and the rest is driven by compressed air, so it is highly safe.

Weight Checking Machine

Fully pneumatic components make sure that the operation is safe.

It has controls that are easy to use, great stability, quick response times and high accuracy.

It provides checking speeds that can be customized to fit different production situations.

Actuator Fixed Machine

Improve the stability of product quality and decrease losses.

It utilizes electrical and compressor - air drive, pneumatic disc - selection, and has high - level safety.

Employ six - head rotation to significantly enhance the production speed.

Auto Cap Inserted Machine

Ensures safe operation with fully pneumatic-driven components.

Accommodates a variety of cap sizes and shapes.

Offers an adjustable sealing speed to cater to diverse production requirements.

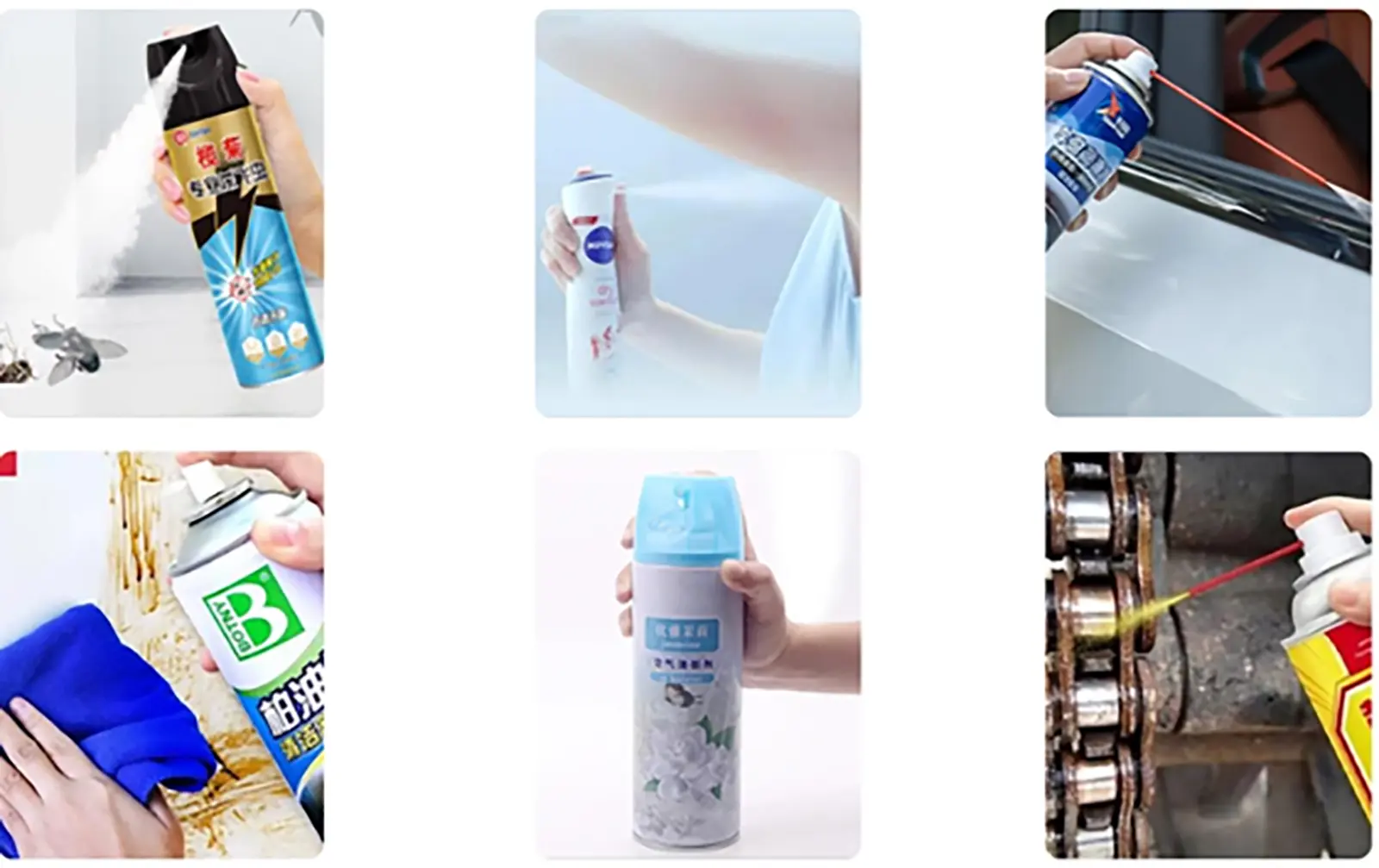

Product Applications

1. Personal Hygiene Market: High - speed aerosol filling technology is a crucial part in making personal care products such as deodorants, hair - styling aerosols, body mists, shaving creams and numerous aerosol cosmetics. It provides efficient and hygienic packaging methods.

2. Domestic and Cleaning Goods Manufacturing: These machines are essential for the production and packaging of household cleaning products like air fresheners, insecticides, disinfectant sprays, furniture polishes and oven cleaners. They contribute to high - production capacity and consistent high - quality products.

3.Pharmaceutical and Healthcare Uses: In the pharmaceutical field, high - speed aerosol filling techniques are vital for manufacturing metered - dose inhalers, topical medications and sanitizing sprays. This requires precise dosage control and strict compliance with regulatory requirements.

2. Domestic and Cleaning Goods Manufacturing: These machines are essential for the production and packaging of household cleaning products like air fresheners, insecticides, disinfectant sprays, furniture polishes and oven cleaners. They contribute to high - production capacity and consistent high - quality products.

3.Pharmaceutical and Healthcare Uses: In the pharmaceutical field, high - speed aerosol filling techniques are vital for manufacturing metered - dose inhalers, topical medications and sanitizing sprays. This requires precise dosage control and strict compliance with regulatory requirements.

Product FAQ

1. Does the machine work with different aerosol formulations?

Yes, it can handle various aerosol formulations used in cosmetics.

2. What's the lifespan of the machine?

With proper maintenance, it can last for many years.

3. Can it be customized?

Yes, certain features can be customized to fit specific needs.

4. Is there a safety lock?

Yes, there's a safety lock to prevent accidents during operation.

5. How is the machine cleaned?

There are specific cleaning procedures to ensure hygiene.

Yes, it can handle various aerosol formulations used in cosmetics.

2. What's the lifespan of the machine?

With proper maintenance, it can last for many years.

3. Can it be customized?

Yes, certain features can be customized to fit specific needs.

4. Is there a safety lock?

Yes, there's a safety lock to prevent accidents during operation.

5. How is the machine cleaned?

There are specific cleaning procedures to ensure hygiene.