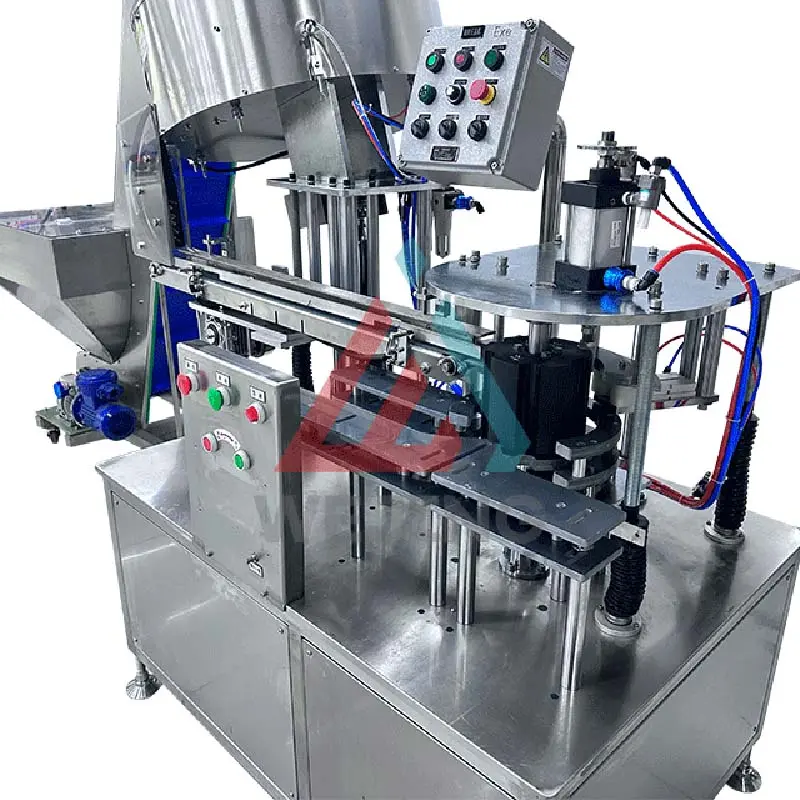

Aerosol Can Capping Machine

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

≥ 120 bottles /min |

|

Suitable can diameter |

35-70mm |

|

Suitable can height |

70-330mm |

|

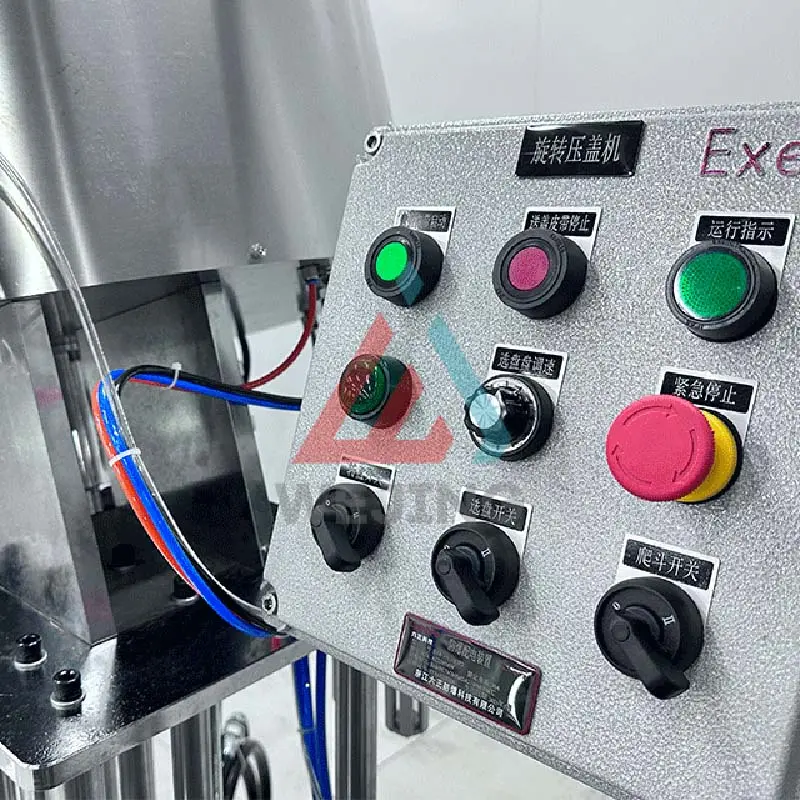

Control |

Electricity control |

|

Alarm system |

Equipped with uncovered alarm device |

|

Air source |

0.8Mpa |

|

Power |

2kW |

|

Size |

1900*1700*850mm |

|

Weight |

300kg |

1. Healthcare: In the medical field, proper packaging and sealing of aerosol - based medical products, such as asthma inhalers, are crucial to ensure product integrity and patient safety.

2. Industrial coatings: When dealing with industrial applications, the handling of aerosol - contained paints, adhesives, and sealants requires specific techniques for optimal performance.

3. Personal care: For the personal care industry, packaging and sealing solutions are vital for products like hairspray and sunscreen to maintain their quality and usability.

4. Home improvement: In home improvement tasks, the aerosol - based sealants, adhesives, and lubricants need appropriate packaging and sealing methods for efficient use.

5. Agriculture: Within the agricultural sector, the packaging and sealing of aerosol - held pesticides, fertilizers, and herbicides are essential to preserve their effectiveness and prevent contamination.

2. Industrial coatings: When dealing with industrial applications, the handling of aerosol - contained paints, adhesives, and sealants requires specific techniques for optimal performance.

3. Personal care: For the personal care industry, packaging and sealing solutions are vital for products like hairspray and sunscreen to maintain their quality and usability.

4. Home improvement: In home improvement tasks, the aerosol - based sealants, adhesives, and lubricants need appropriate packaging and sealing methods for efficient use.

5. Agriculture: Within the agricultural sector, the packaging and sealing of aerosol - held pesticides, fertilizers, and herbicides are essential to preserve their effectiveness and prevent contamination.

Operate Guide

1. Power Initiation: Turn on the machine and make sure that every component is correctly linked.

2. Can Loading: Put the aerosol cans onto the conveyor belt or the relevant feeding structure.

3. Cap Loading: Position the caps inside the cap feeder or the hopper.

4. Capping Procedure: The machine automatically adjusts and applies caps to the cans at a rapid pace.

5.Inspection and Quality Assurance: The machine might have inspection functions to guarantee that the capping is done correctly.

2. Can Loading: Put the aerosol cans onto the conveyor belt or the relevant feeding structure.

3. Cap Loading: Position the caps inside the cap feeder or the hopper.

4. Capping Procedure: The machine automatically adjusts and applies caps to the cans at a rapid pace.

5.Inspection and Quality Assurance: The machine might have inspection functions to guarantee that the capping is done correctly.

Product FAQ

1. What's the first step to operate the machine?

First, make sure the machine is properly installed and connected to a stable power source. Then turn on the power switch to start it up.

2. How should I prepare the aerosol cans for capping?

Ensure the cans are clean and dry. Place them in an orderly manner on the conveyor belt or in the feeding system designed for the cans.

3. What about the caps? How to handle them?

The caps should be placed in the cap feeder or hopper. Make sure they are of the right size and type for the aerosol cans.

4. How fast can this capping machine work?

The speed varies, but it's a high - speed capping machine. It can cap a large number of aerosol cans per minute, usually depending on the model and its settings.

5. How to ensure the capping quality?

The machine usually has inspection mechanisms. It checks if the caps are properly aligned and tightened during the capping process. Regular maintenance also helps to keep the capping quality stable.

First, make sure the machine is properly installed and connected to a stable power source. Then turn on the power switch to start it up.

2. How should I prepare the aerosol cans for capping?

Ensure the cans are clean and dry. Place them in an orderly manner on the conveyor belt or in the feeding system designed for the cans.

3. What about the caps? How to handle them?

The caps should be placed in the cap feeder or hopper. Make sure they are of the right size and type for the aerosol cans.

4. How fast can this capping machine work?

The speed varies, but it's a high - speed capping machine. It can cap a large number of aerosol cans per minute, usually depending on the model and its settings.

5. How to ensure the capping quality?

The machine usually has inspection mechanisms. It checks if the caps are properly aligned and tightened during the capping process. Regular maintenance also helps to keep the capping quality stable.