Aerosol Can Filling Sealing Machine

1. Automated Fabrication Procedure

2. High-Performance Productivity

3. Accurate Dosing Mechanism

4. Smart Surveillance and Regulation System

5. Swift Adaptation and Conversion

2. High-Performance Productivity

3. Accurate Dosing Mechanism

4. Smart Surveillance and Regulation System

5. Swift Adaptation and Conversion

6. Power Conservation

7. Expedited Servicing and Alteration

8. Quality Evaluation and Origin Tracing Framework

9. Man-Machine Interaction Platform

10. Self-Operating Servicing Facility

7. Expedited Servicing and Alteration

8. Quality Evaluation and Origin Tracing Framework

9. Man-Machine Interaction Platform

10. Self-Operating Servicing Facility

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

40-50 |

|

Liquid filling volume (ml) |

10-600( can be customized) |

|

Gas filling volume (ml) |

10-600( can be customized) |

|

Filling heads |

2 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

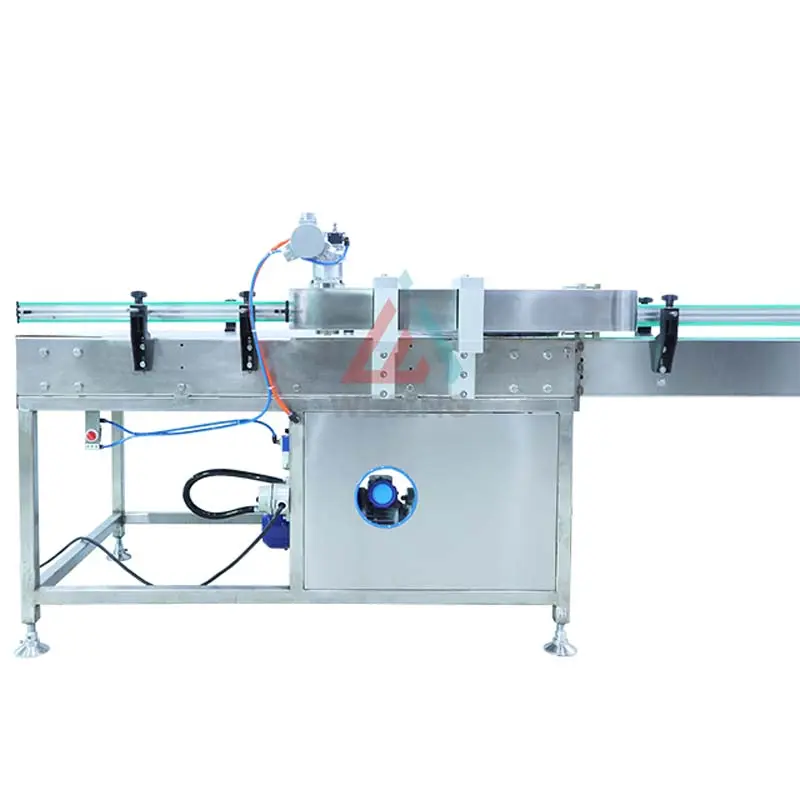

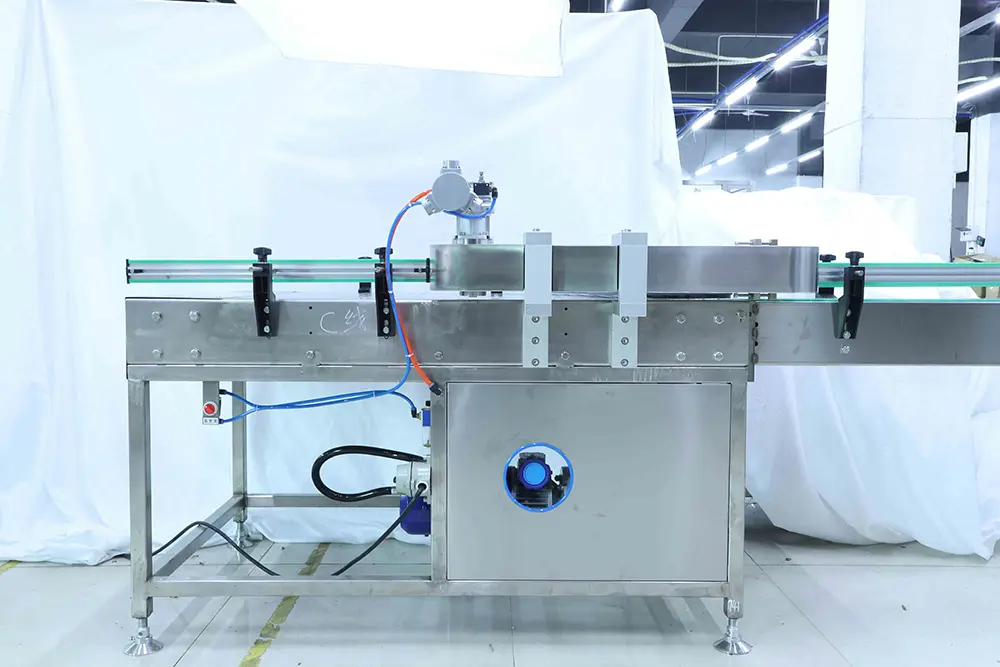

Auto Can Feeding Machine

The variable speed bottle feeding table serves as the fundamental feeding infrastructure for the aerosol spray bottle filling line. Operators are required to place empty bottles onto the table. Driven by a gear motor, the bottles will be orderly arranged and transferred to the conveyor. This machine is adaptable to bottles of varying sizes and is thus capable of performing its operations effectively.Aerosol Filling Sealing Production Line

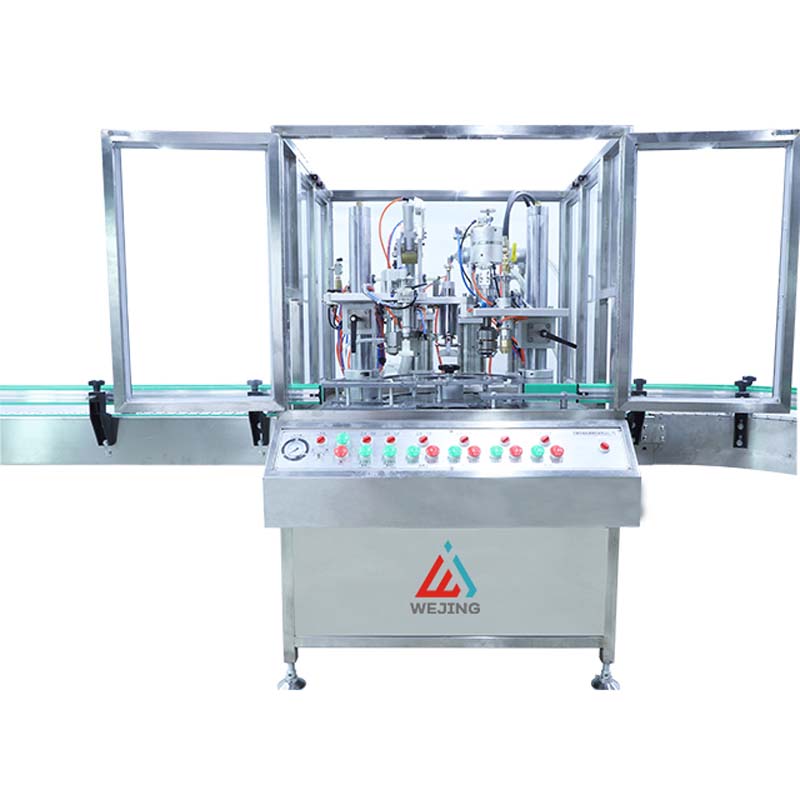

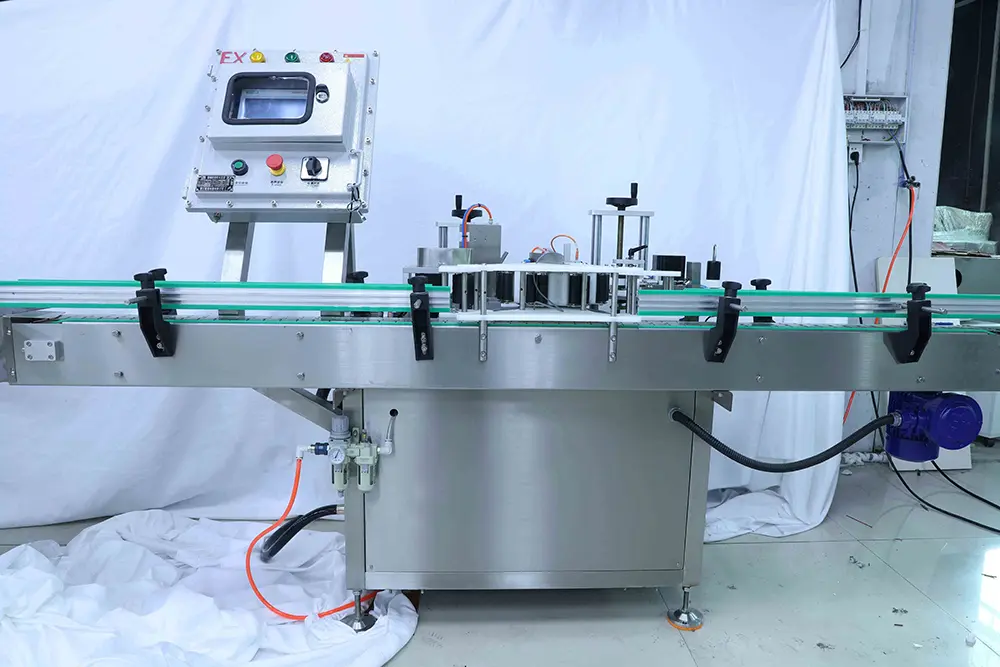

The QGJ70 Automatic aerosol filling production line consists of a rotary table equipped with liquid filling heads, insert valve components, crimping heads and gas filling heads. It also includes a compressed air piston pump and a conveyor belt.This production line operates in an automated and highly efficient manner. It is designed in such a way that it will not commence the filling of materials unless there are empty cans present. Moreover, its filling accuracy rate exceeds 99%, ensuring a precise and reliable filling process.

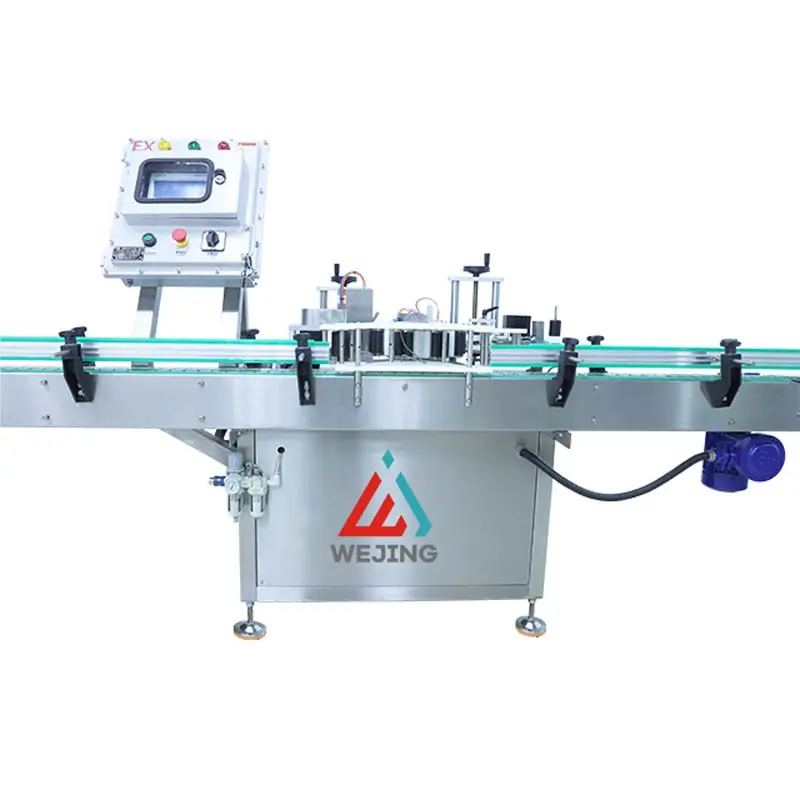

Auto Actuator Fixed Machine

This machine allows for convenient adjustment. The height can be modified by simply lifting the handle. When it comes to cans with different diameters, all that is required is to substitute the star wheel molds.

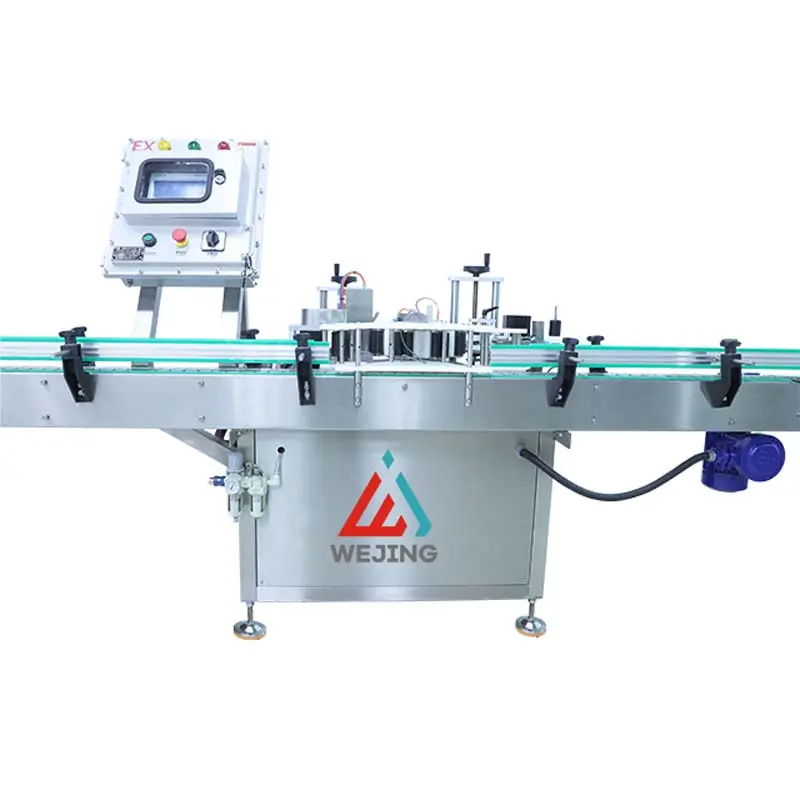

Auto Tube Stick Machine

The tube is automatically attached to the aerosol bottle. It is applicable to various types of aerosol cans. With a high level of automation, convenient operation procedures, and being safe and dependable, it stands as the optimal selection for aerosol can manufacturers.

Packing and Delivery

The machine is packaged with plastic films internally and encased in a fumigation wooden case externally.

Our wooden case is highly robust and capable of withstanding prolonged sea shipments.

The machine is also wrapped with a preservative film, which serves to prevent the ingress of salty seawater, thereby safeguarding the machine from corrosion.

Our wooden case is highly robust and capable of withstanding prolonged sea shipments.

The machine is also wrapped with a preservative film, which serves to prevent the ingress of salty seawater, thereby safeguarding the machine from corrosion.

Our Service

Pre-sale Services:

1. Offering proficient technical assistance.

2. Dispatching the product brochure and operational guidelines.

3. Should you have any inquiries, feel free to reach out to us either via online chat or email. We assure you of an immediate response.

4. We highly welcome personal calls or on-site visits.

During-sale Services:

1. We pledge integrity and equity, and are delighted to act as your procurement advisors.

2. We ensure punctual delivery, top-notch quality and accurate quantity, strictly adhering to the contractual stipulations.

After-sale Services:

1. For our products, a one-year warranty is provided along with lifelong servicing.

2. There is a substantial inventory of components and frequently replaced parts.

1. Offering proficient technical assistance.

2. Dispatching the product brochure and operational guidelines.

3. Should you have any inquiries, feel free to reach out to us either via online chat or email. We assure you of an immediate response.

4. We highly welcome personal calls or on-site visits.

During-sale Services:

1. We pledge integrity and equity, and are delighted to act as your procurement advisors.

2. We ensure punctual delivery, top-notch quality and accurate quantity, strictly adhering to the contractual stipulations.

After-sale Services:

1. For our products, a one-year warranty is provided along with lifelong servicing.

2. There is a substantial inventory of components and frequently replaced parts.