Aerosol Cans Weight Checker Machine

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

≥ 120 bottles/min |

|

Transmission part |

reduction motor with variable frequency drive |

|

Installation |

The tool cabinet shall be installed under the platform, the door plate thickness shall be ≥ 1.5mm, and the handle shall be firm |

|

Size |

1600*1680*850mm |

|

Equipment sealing plate thickness |

≥ 1.5mm plate |

1. Exceptional Precision: Our weighing machine adopts cutting - edge technology and a highly precise scale, which guarantees precise and stable weighing for aerosol products.

2. Swift Operation: Thanks to its fully automated feature, this machine enables rapid and efficient weighing, enhancing productivity and cutting down production time.

2. Swift Operation: Thanks to its fully automated feature, this machine enables rapid and efficient weighing, enhancing productivity and cutting down production time.

3. Quality Guarantee: The built - in checkweigher function ensures that each aerosol product complies with the stipulated weight requirements, thus maintaining consistent quality and satisfying customers.

4. Intuitive Interface: Our weighing machine is crafted with an interface that's easy to use, facilitating quick operation and allowing for speedy setup and adjustments.

Diverse Application: This machine fits a broad array of aerosol products, adapting to different sizes and weights, making it a flexible solution for multiple industries

4. Intuitive Interface: Our weighing machine is crafted with an interface that's easy to use, facilitating quick operation and allowing for speedy setup and adjustments.

Diverse Application: This machine fits a broad array of aerosol products, adapting to different sizes and weights, making it a flexible solution for multiple industries

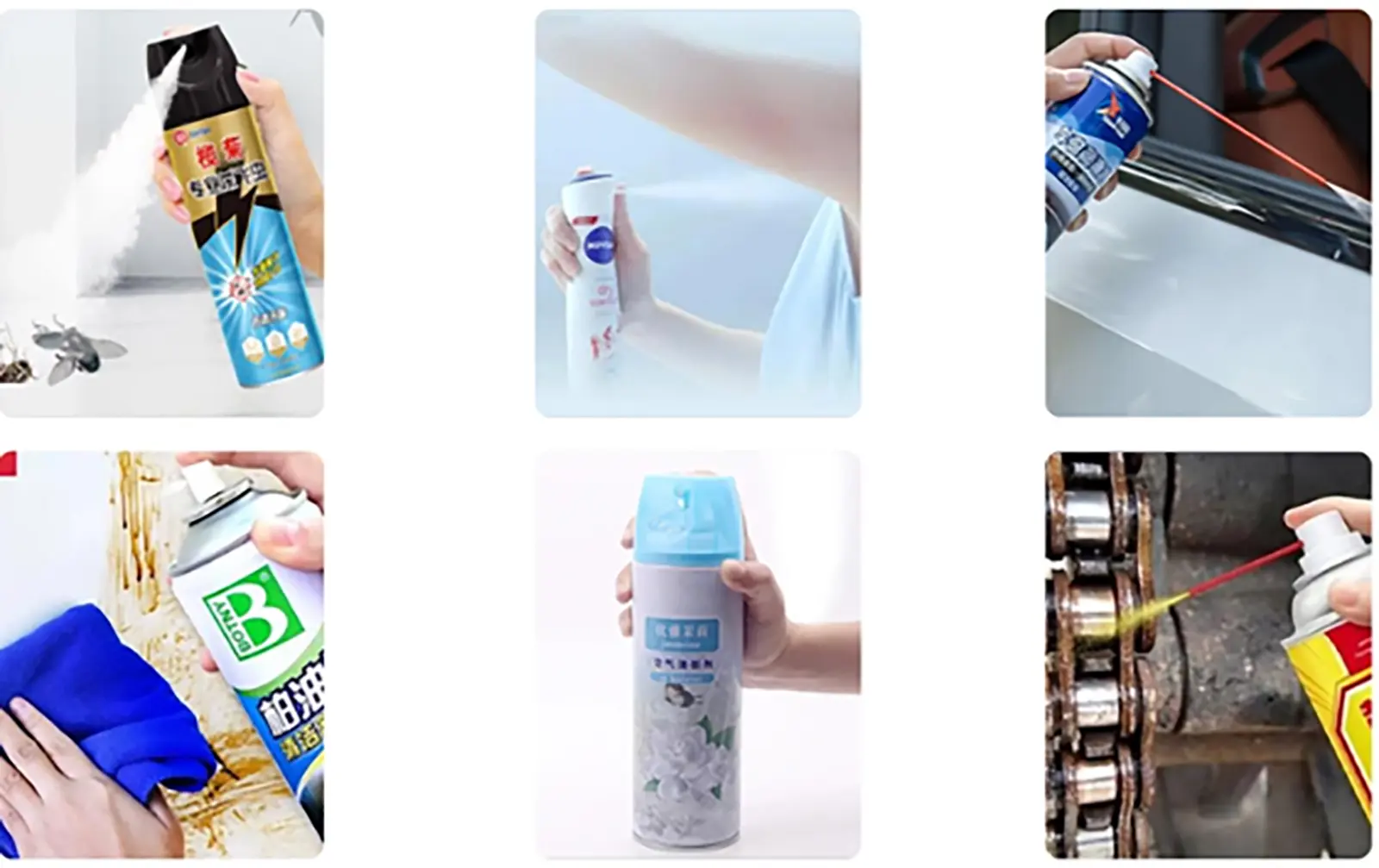

Product Applications

1. Pharmaceutical Industry: The Fully Automatic Aerosol Weighing Machine plays a crucial role in the pharmaceutical realm. It accurately gauges the weight of aerosol products, thereby ensuring the dosage is spot - on and all regulatory stipulations are met.

2. Personal Care Industry: In the personal care industry, this remarkable machine is put to work for weighing aerosol products. Whether it's hair sprays that give volume, deodorants that keep us fresh, or body mists that add a touch of fragrance, this machine ensures the quality remains consistent throughout.

3. Household Products: When it comes to household products, the Fully Automatic Aerosol Weighing Machine is indispensable. It precisely measures the weight of aerosol products used for cleaning our homes, freshening the air within, and repelling those pesky insects.

4. Automotive Industry: In the automotive industry, this machine fits in perfectly. It is ideal for weighing aerosol products that are used for automotive care. From making tires shine to providing lubrication and inhibiting rust, it ensures the packaging is both accurate and efficient.

6.Industrial Applications: For various industrial applications, the Fully Automatic Aerosol Weighing Machine is a key asset. It weighs aerosol products such as paints, coatings, and adhesives, making sure the formulations are precise and the results are consistently reliable.

2. Personal Care Industry: In the personal care industry, this remarkable machine is put to work for weighing aerosol products. Whether it's hair sprays that give volume, deodorants that keep us fresh, or body mists that add a touch of fragrance, this machine ensures the quality remains consistent throughout.

3. Household Products: When it comes to household products, the Fully Automatic Aerosol Weighing Machine is indispensable. It precisely measures the weight of aerosol products used for cleaning our homes, freshening the air within, and repelling those pesky insects.

4. Automotive Industry: In the automotive industry, this machine fits in perfectly. It is ideal for weighing aerosol products that are used for automotive care. From making tires shine to providing lubrication and inhibiting rust, it ensures the packaging is both accurate and efficient.

6.Industrial Applications: For various industrial applications, the Fully Automatic Aerosol Weighing Machine is a key asset. It weighs aerosol products such as paints, coatings, and adhesives, making sure the formulations are precise and the results are consistently reliable.

Operate Guide

1. Before starting the operation, make sure the machine has been correctly installed and connected to both the power source and air supply, in accordance with the manufacturer's guidelines.

2. On the control panel, configure the intended weight parameters, such as the target weight, tolerance level, and the size of each batch.

3. Position the aerosol products onto the conveyor belt, making certain they are accurately aligned and spaced to enable precise weighing.

4. Initiate the machine and keep an eye on the weighing procedure to guarantee that every aerosol product's weight falls within the specified tolerance interval.

5. Routinely examine and clean the machine, covering the conveyor belt and the weighing scale, to preserve accuracy and avoid any contamination of the products.

2. On the control panel, configure the intended weight parameters, such as the target weight, tolerance level, and the size of each batch.

3. Position the aerosol products onto the conveyor belt, making certain they are accurately aligned and spaced to enable precise weighing.

4. Initiate the machine and keep an eye on the weighing procedure to guarantee that every aerosol product's weight falls within the specified tolerance interval.

5. Routinely examine and clean the machine, covering the conveyor belt and the weighing scale, to preserve accuracy and avoid any contamination of the products.