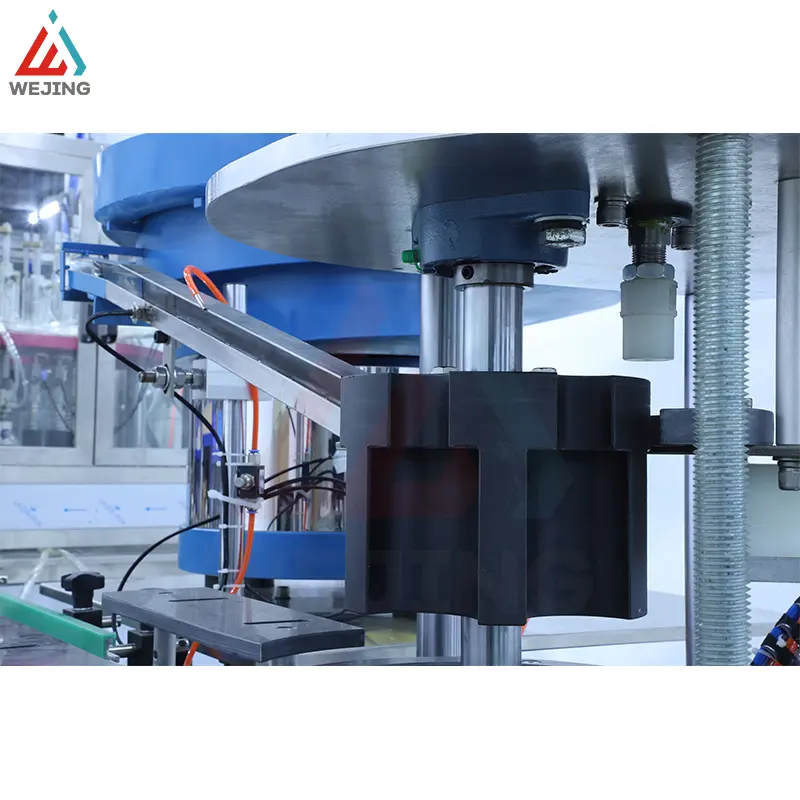

Aerosol Conjoined Lid Capping Machine

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Refueling capacity (cans/minute) |

60-70 cans/min |

|

Applicable cans diameter (mm) |

35-70 (customizable) |

|

Applicable cans height (mm) |

70-300 (customizable) |

|

Applicable valve (мм) |

25,4 (1 inch) |

|

Propellant |

N2, compressed air |

|

Max gas consumption (m3/min) |

6m3/min |

|

Power (KW) |

AC 380V/50HZ |

|

Air source |

0.6-0.7Mpa |

1. Place the aerosol can in a specific working position.

2. The integrated cover is transported to the press fit position through a conveying device.

2. The integrated cover is transported to the press fit position through a conveying device.

3. Start the pressing mechanism and apply a certain amount of pressure to press the connected cover onto the aerosol can.

4. After completing the pressing process, the aerosol can is transported out of the equipment for the next step of packaging or other procedures.

4. After completing the pressing process, the aerosol can is transported out of the equipment for the next step of packaging or other procedures.

PRODUCT Advantages

1. Efficient production: Adopting advanced automation technology to achieve high-speed batch production.

2. Precise filling: Equipped with a high-precision measurement system to ensure consistent filling volume for each bottle of product.

3. Flexible and applicable: The parameters can be adjusted to adapt to different specifications and types of aerosol products.

4. Reliable quality: Using high-quality materials and components to ensure the stability and durability of the equipment.

5. Easy to operate: The user-friendly interface makes it convenient for workers to quickly master and operate the equipment.

2. Precise filling: Equipped with a high-precision measurement system to ensure consistent filling volume for each bottle of product.

3. Flexible and applicable: The parameters can be adjusted to adapt to different specifications and types of aerosol products.

4. Reliable quality: Using high-quality materials and components to ensure the stability and durability of the equipment.

5. Easy to operate: The user-friendly interface makes it convenient for workers to quickly master and operate the equipment.

PRODUCT Maintenance

1. Clean the equipment on a regular basis to keep it clean and hygienic.

2. Examine all the components of the equipment to make sure they are working properly. If there are any damaged or worn - out parts, replace them promptly.

3. Lubricate the equipment regularly to guarantee the smooth operation of its moving parts.

4. Operators should undergo training, get acquainted with the operation and maintenance techniques of the equipment, and operate it in strict accordance with the operating procedures.

2. Examine all the components of the equipment to make sure they are working properly. If there are any damaged or worn - out parts, replace them promptly.

3. Lubricate the equipment regularly to guarantee the smooth operation of its moving parts.

4. Operators should undergo training, get acquainted with the operation and maintenance techniques of the equipment, and operate it in strict accordance with the operating procedures.

PRODUCT Applications

It can be widely applied in various fields. It is an ideal choice for the production of aerosol sprays in cosmetics, daily chemical and pharmaceutical industries. This production line ensures precise gas filling and packaging, providing high-quality and efficient solutions for your production needs. Whether it is personal care products, household cleaners or pharmaceutical sprays, the filling machine production line can meet your requirements. Its automated operation and precise control help improve production efficiency and product quality.