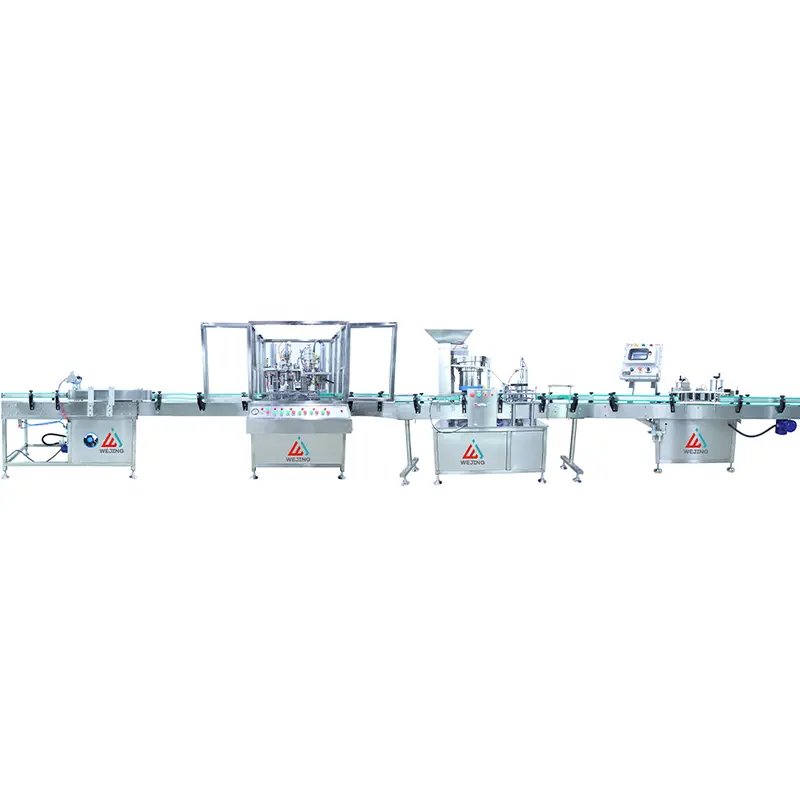

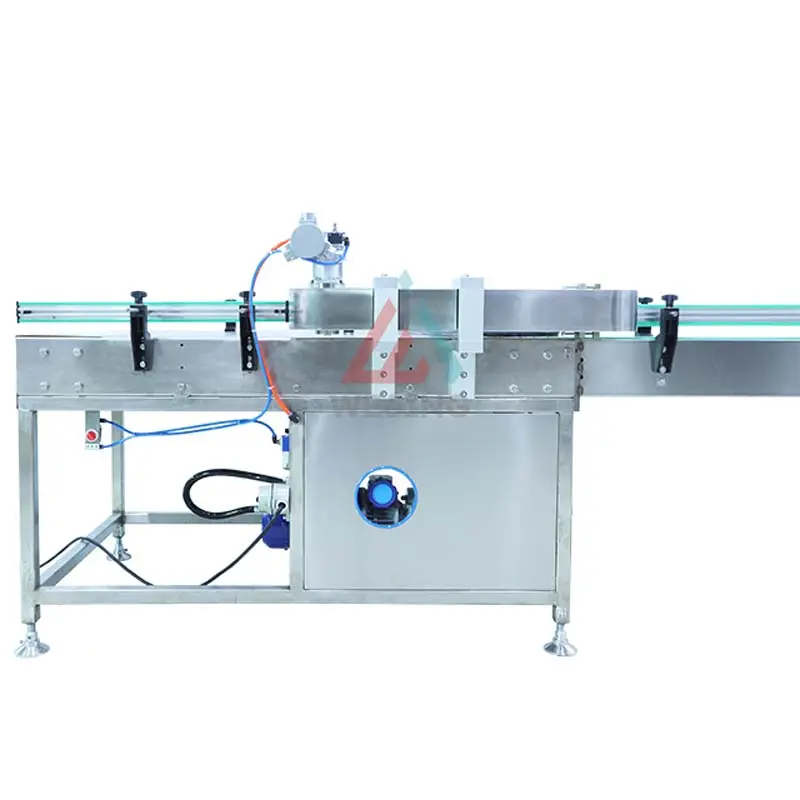

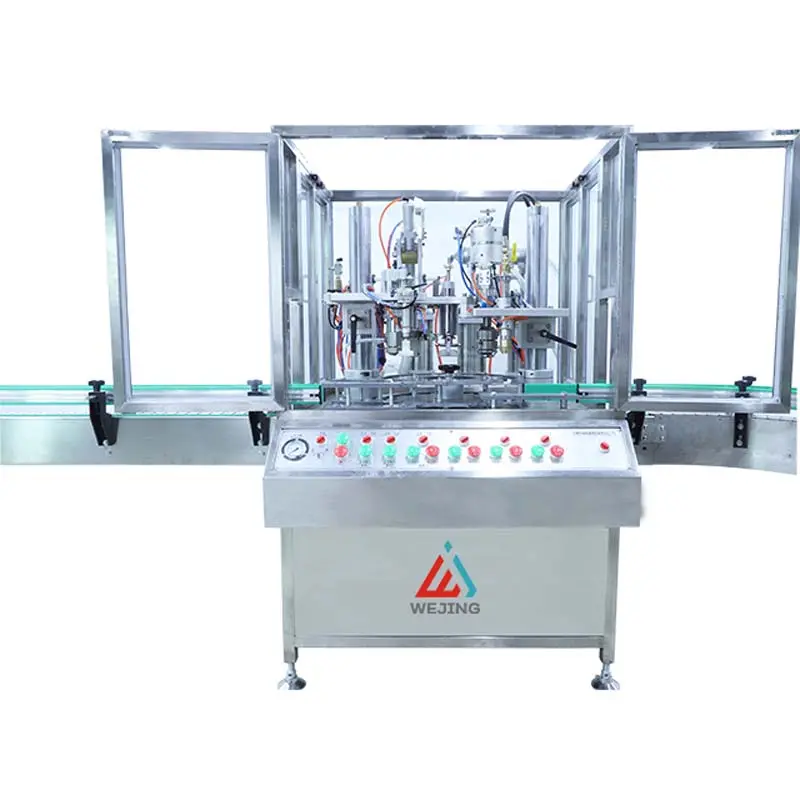

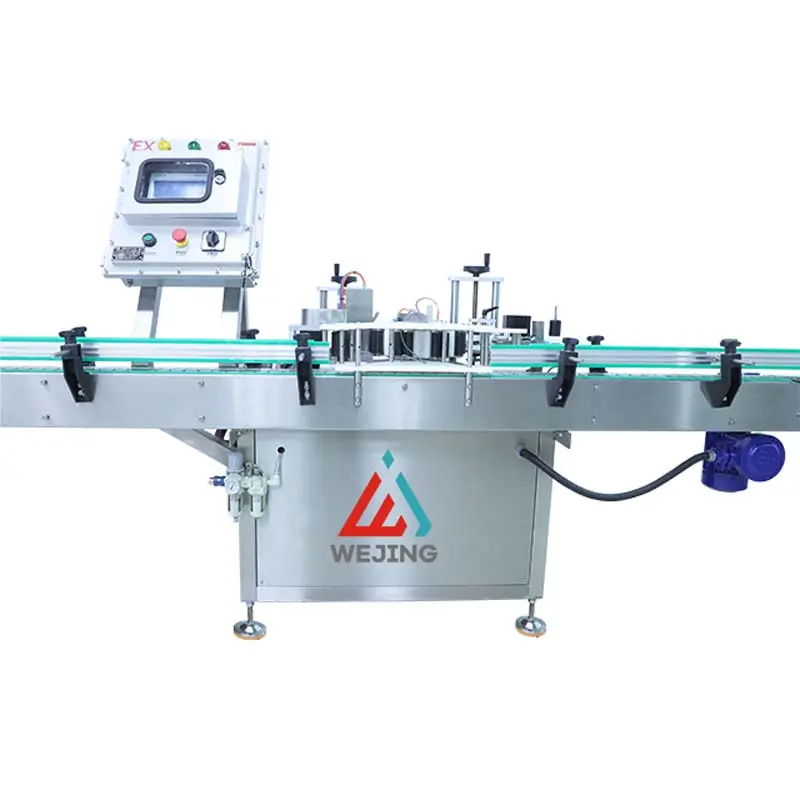

Aerosol Filling Line With Tube Stick

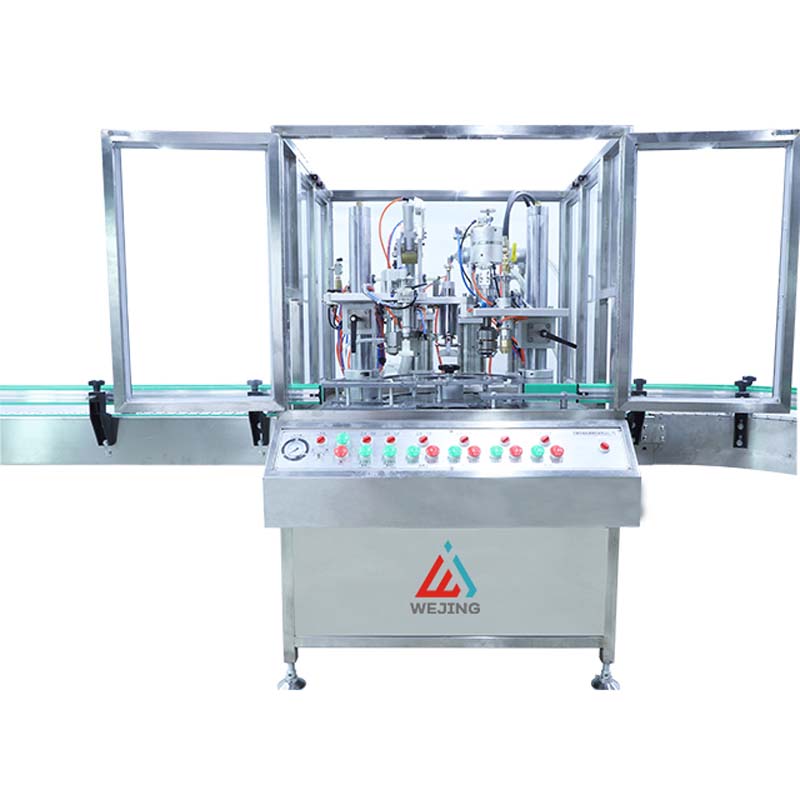

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Name |

Description |

|

Liquid filling heads |

2 heads |

|

Gas filling heads |

2 heads |

|

Sealing head |

1 heads |

|

Filling capacity |

30-35 cans/min |

|

Liquid filling volume |

10-600 ml ( can be customized) |

|

Gas filling volume |

10-600ml( can be customized) |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter |

35 - 70mm( can be customized) |

|

Applicable cans height (mm) |

80 - 300mm( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure |

0.6 - 0.8Mpa |

|

Max gas consumption |

5m3/min |

|

Material |

SS304 ( some parts can be SS316) |

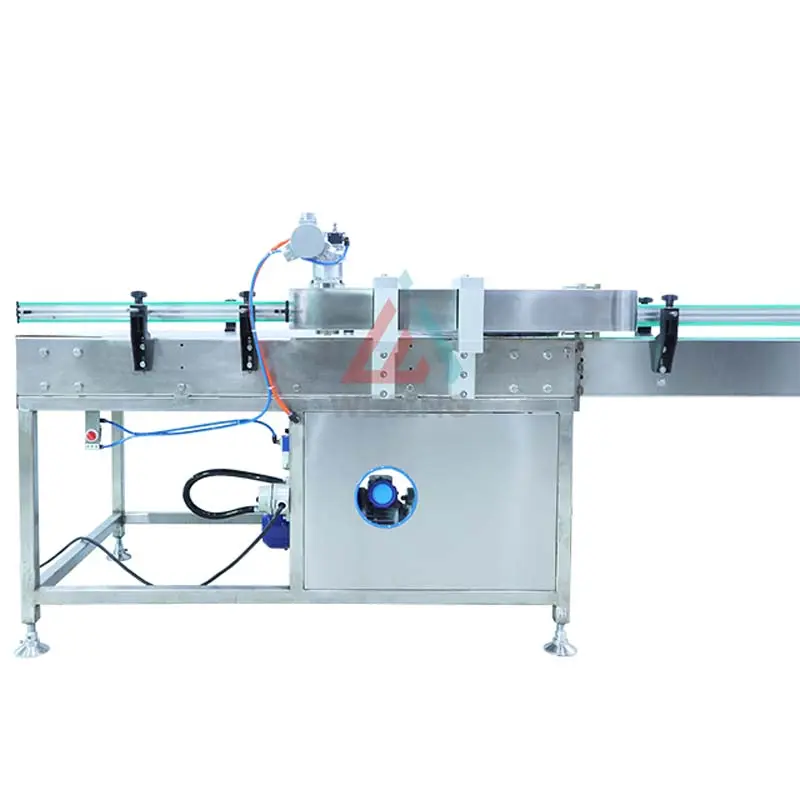

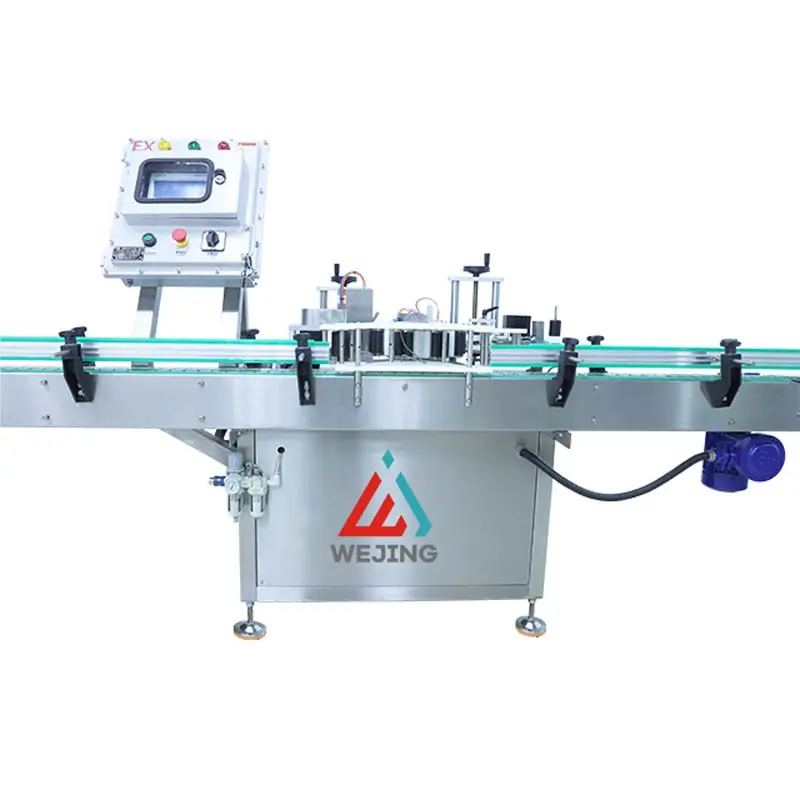

1. It has high automation characteristics and can automatically complete filling operations, greatly improving production efficiency.

2. Achieve precise measurement, ensure accurate filling volume, and effectively improve product quality.

2. Achieve precise measurement, ensure accurate filling volume, and effectively improve product quality.

3. The operation is very simple, reducing the difficulty of the operation and minimizing the occurrence of operational errors.

4. Excellent compatibility, capable of filling card type gas containers of different specifications and shapes.

4. Excellent compatibility, capable of filling card type gas containers of different specifications and shapes.

5. It has reliable and durable quality, can withstand high-intensity production tasks, and effectively reduces costs.

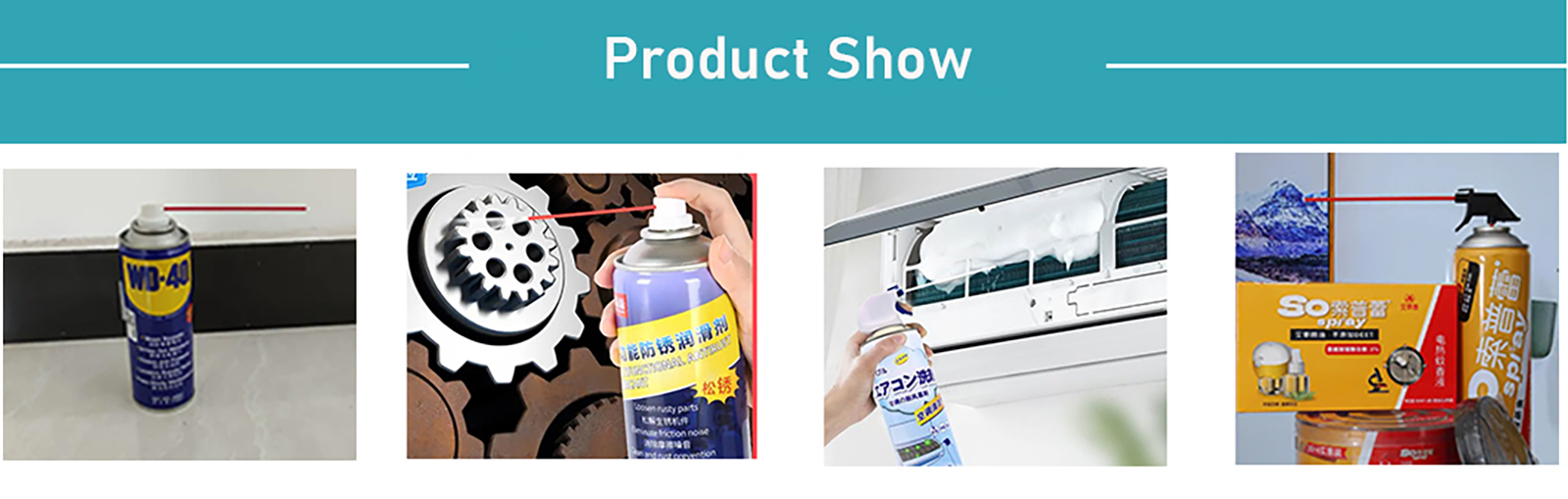

product Applications

Can be used for products such as rust removers, insecticides, and air conditioning cleaning agents

Packing and Delivery

1. Careful protective packaging: First, fix the machine with stretch film, and then use wooden boxes for all-round protection to ensure that it is not damaged during transportation.

2. Efficient transportation services: Based on customer needs and product characteristics, we provide a variety of transportation options, such as land, sea, air, etc., to meet different transportation time and cost requirements

2. Efficient transportation services: Based on customer needs and product characteristics, we provide a variety of transportation options, such as land, sea, air, etc., to meet different transportation time and cost requirements

After Sales Service

1. The equipment comes with a 2-years warranty, during which any malfunctions can be repaired free of charge.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.