Aerosol Filling Machine Bag On Valve

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Filling capacity (cans/min) |

45-60cans/min |

|

Liquid filling volume (ml) |

10-300ml/head |

|

Gas filling accuracy |

≤±1% |

|

Liquid filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35-70 ( can be customized) |

|

Applicable cans height (mm) |

70-300 ( can be customized) |

|

Applicable valve (mm) |

25.4 (1 inch) |

|

Propellant |

N2, compressed air |

|

Max gas consumption (m3/min) |

6m3/min |

|

Power (KW) |

AC 380V/50HZ |

|

Air source |

0.6-0.7Mpa |

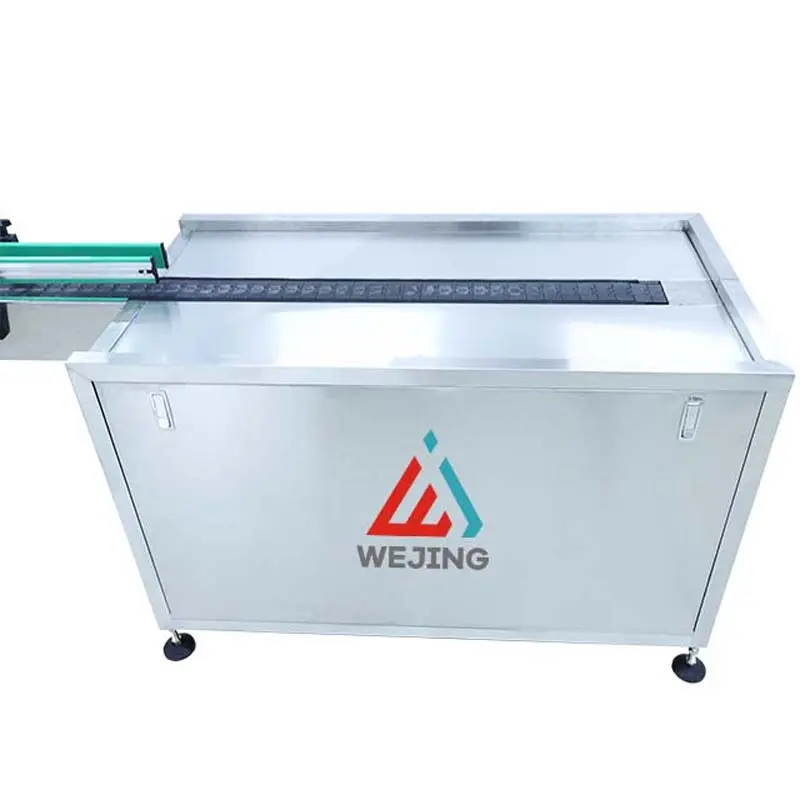

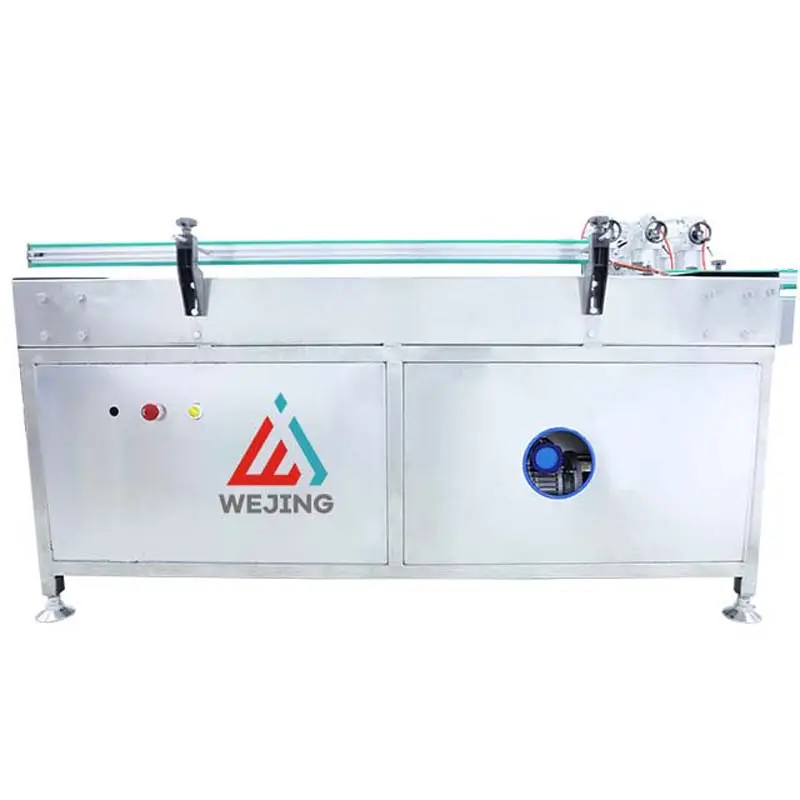

Can Feeding Machine

Make certain that the cans are arranged properly and orderly as they move along the conveyor belt.

Machine filling system

Begin by introducing propellant gas into the aerosol canister, followed by sealing it tightly. This action facilitates the seamless combination of the substances within the canister and the propellant, resulting in the formation of an aerosol. Here are the crucial sequential steps:

1. Compress the gas and load it into the canister.

2. Pour the liquid component into the canister.

3. Gauge the pressure inside the canister.

4. Conduct a thorough cleaning process.

Actuator Fixed Machine

Secure the spray nozzle tightly onto the valve of the bottle. This connection is designed to enable users to easily release the liquid in the form of a delicate mist spray.PRODUCT Advantages

1. This equipment has the capacity to achieve the concealed sealing of aerosol cans and perform liquid quantitative filling. Its control mechanism adopts the fashionable PLC combined with a touch - screen device. It is noted for its secure and dependable operation, excellent airtightness, accurate measurement, and high precision in repeated filling.

2. Specifically engineered for the filling of diverse aerosol products such as sprays, foams, and liquids, this machine comes with a user - friendly interface presented via a touch - screen display. This enables operators to effortlessly manage and oversee the filling procedure. Equipped with multiple filling nozzles, the machine can fill multiple cans simultaneously.

3. The innovative Bov system is developed not merely to fabricate an outstanding spray dispensing system, but also to minimize our ecological impact through a sustainable packaging procedure. In comparison with traditional aerosol spray technology and other alternative packaging methods, BoV aerosols offer advantages to manufacturers, consumers, and the environment alike.

2. Specifically engineered for the filling of diverse aerosol products such as sprays, foams, and liquids, this machine comes with a user - friendly interface presented via a touch - screen display. This enables operators to effortlessly manage and oversee the filling procedure. Equipped with multiple filling nozzles, the machine can fill multiple cans simultaneously.

3. The innovative Bov system is developed not merely to fabricate an outstanding spray dispensing system, but also to minimize our ecological impact through a sustainable packaging procedure. In comparison with traditional aerosol spray technology and other alternative packaging methods, BoV aerosols offer advantages to manufacturers, consumers, and the environment alike.

PRODUCT Applications

This collection of equipment has found extensive application across various sectors including healthcare, fire prevention, and the cosmetics industry. It is suitable for packaging a wide range of aerosol products such as water - based cleaning agents, disinfectants, household fire extinguishing substances, tear gases, shaving foams, cosmetic sprays, and photocatalysts. Due to cost - effectiveness considerations, there is a diverse selection of propellants available, like nitrogen (N₂), carbon dioxide (CO₂), argon (Ar), liquefied petroleum gas (LPG), and in some cases, compressed air.

At present, we're not certain about the specific product you manufacture. However, our company is well - equipped to provide you with a plethora of machinery options, including semi - automatic, fully - automatic models, and complete production lines, tailored to your actual requirements. Should you have any additional needs or inquiries, please do not hesitate to inform us.

Household Maintenance:

Air fresheners to create a pleasant indoor atmosphere.

Insecticides for pest control.

Furniture sprays for protection and polishing.

Pesticides for garden and agricultural use.

Leather sprays to maintain the quality of leather goods.

Toilet sprays for a fresh and clean toilet environment.

Glass sprays for streak - free window and glass cleaning.

Personal Care:

Perfumes for a fragrant personal touch.

Deodorants to control body odor.

Hair sprays for styling and hold.

Shaving gels or foams for a smooth shaving experience.

Mouth sprays for oral hygiene and freshness.

Cosmetic sprays for makeup application and setting.

Self - defence sprays for personal safety.

Police sprays for law enforcement purposes.

Automotive Care:

Tyre repair sprays for quick tyre fixes.

Car window sprays for clear visibility.

Upholstery sprays to clean and protect vehicle interiors.

Engine cleaner sprays to maintain engine performance.

Other Industrial Applications

Spray painting for various coat