Semi Auto Aerosol Cap Fixed Machine

The semi-automatic capping machine consists of three parts: a capping platform, a turntable, and a capping mechanism. This equipment is used for packaging the outer caps of aerosol products. The device adopts a manual cover placement and automatic cover pressing working mode. The operator places the outer cover of the aerosol can in a specific position and then starts the equipment. The device automatically presses the outer cover onto the aerosol can through a mechanical transmission system and control system. During the capping process, the equipment will ensure a tight fit between the outer cover and the aerosol can based on the set pressure and time parameters, achieving a good sealing effect.

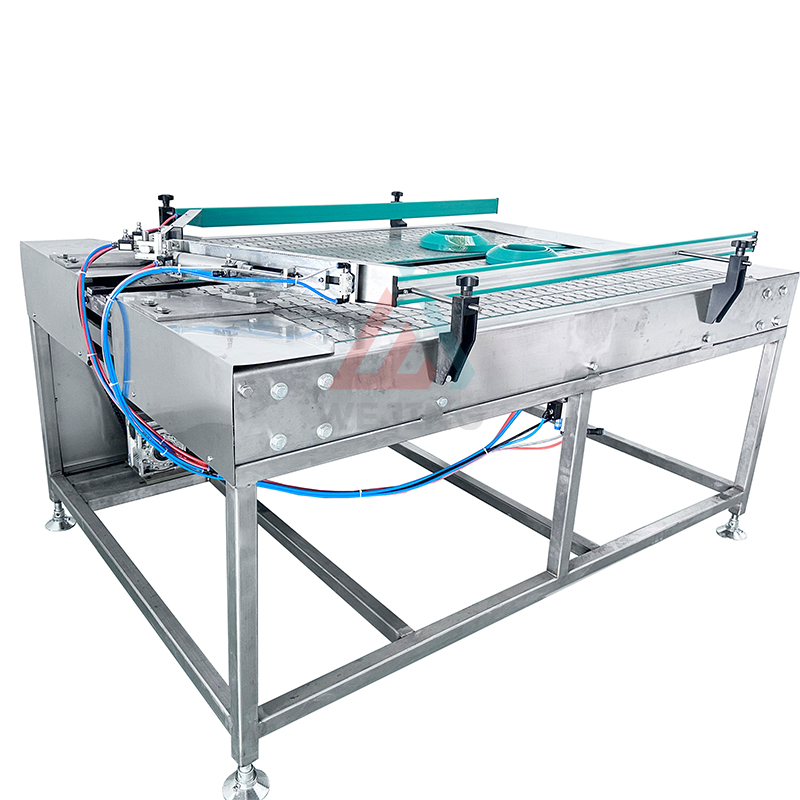

Glass Bead Inserted Machine For Aerosols

Automatic glass bead machine is composed of a funnel, a turntable and an automatic glass bead selection device.

Aerosol Spray Can Feeding Machine

Can feeding machine is the front-end equipment of the fully automatic aerosol filling line. It mainly uses mechanical vibration or rotating devices to organize messy bottles into a state where the bottle mouth is facing up and arranged neatly, and then transports the bottles in an orderly manner to the next process, greatly improving the initial efficiency of filling.

QGJ70 Air Freshener Aerosol Filling M...

QGJ70 fully - automated aerosol filling line is applicable to the production of automotive care aerosol products, self - spray paint, insecticide aerosols, mold release agents and other goods. The whole set of equipment is controlled by pneumatic components. The conveyor motor is explosion - proof. The filling measurement is digitally adjusted with high precision. On - site factory training is provided. Its production capacity is 60 - 70 cans per minute.

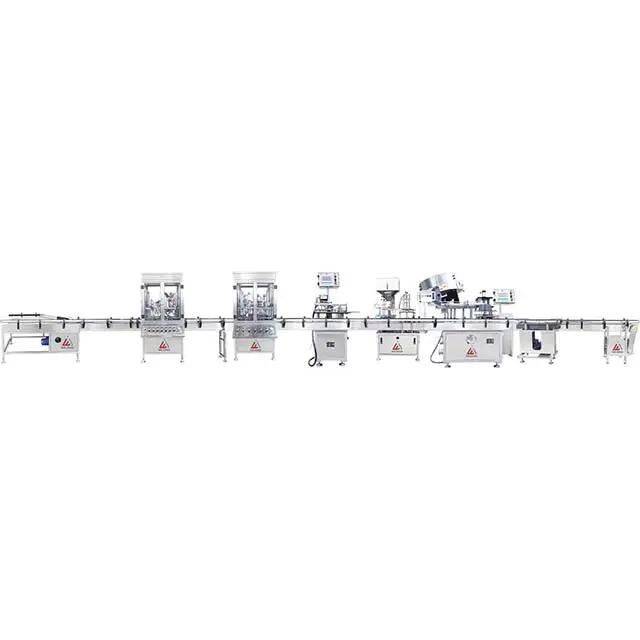

QGJ70 Snow Spray Paint Filling Machine

Aerosol filling line is particularly designed for the production of traditional aerosols, and it is suitable for simple and cost - efficient applications. It consists of can arrangement devices, liquid filling machines, and gas inflators. There are also optional configurations such as fully - automatic valve insertion equipment, automatic capping machines, and automatic weighing machines. The production line is furnished with fully pneumatic control logic to deal with potential environmental hazards and offers a user - friendly system for maintenance requirements.

Automatic Aerosol Actuator Fixed Machine

Automatic aerosol actuator fixed machine is a crucial part of the fully - automatic aerosol filling line. It is specifically designed to guarantee the efficient and precise nozzle - pressing of different aerosol products, such as aerosol gel, artificial aerosol, combustible aerosol, and solid aerosol. Thanks to its automation function, this machine streamlines the production process and ensures the safety and consistent sealing of each aerosol can. Its advanced technology and safety measures make it an essential tool for aerosol manufacturers, enhancing productivity and maintaining the highest quality standards in aerosol packaging.

Middle Speed Aerosol Filling Machine

This aerosol comes with an automatic adjustment feature, ensuring safety, reliability, and convenience. It also has a counting function, which helps cut down on labor costs. It can be applied to a wide range of aerosol products, such as shaving cream, air freshener, insecticide, disinfectant, hair gel, fire foam, and more.

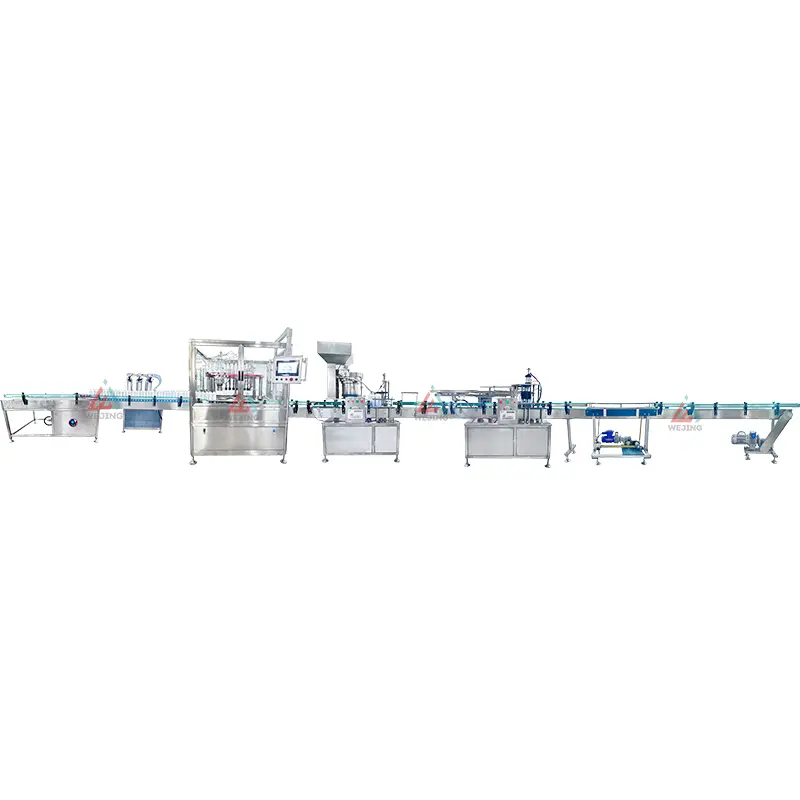

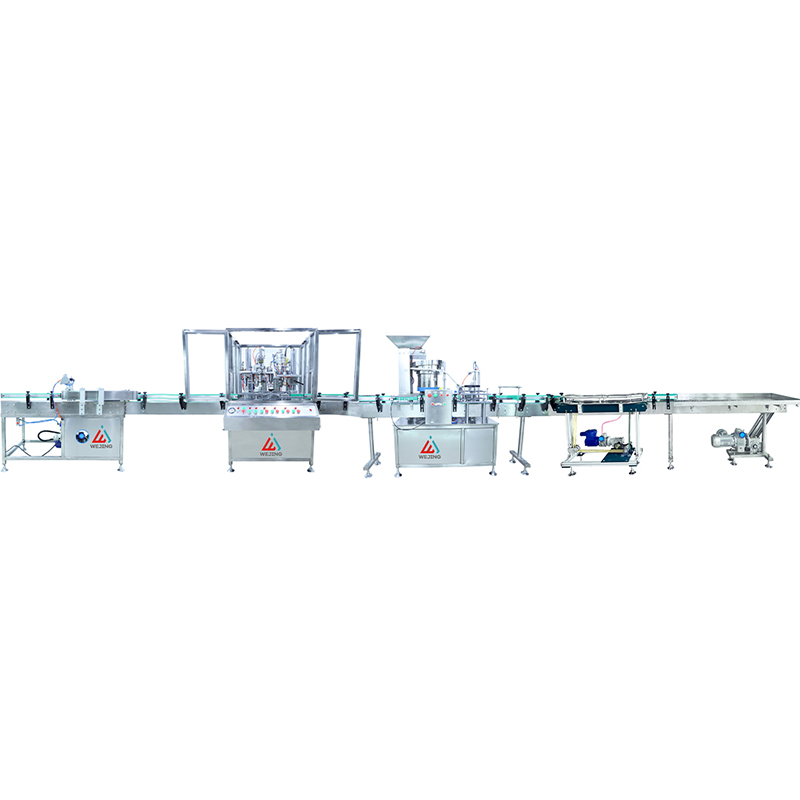

3600 BPH Aerosol Filling Line

This state-of-the-art Automatic Aerosol Filling Machine Line exhibits remarkable productivity, churning out 3600 to 4200 cans within an hour, with the output contingent upon the fill volume. It offers effortless adjustability spanning from 10 to 1200 ml. The filling station is ingeniously crafted to aptly handle diverse aerosol substances. Powered by a pneumatic mechanism, it ensures filling precision within a margin of ±1%. It also features a smart safeguard that precludes filling, inserting, or capping operations in the absence of a bottle.

QGJ70 Automatic Aerosol Filling Line

Fully Automated Aerosol Filling Systems consist of a wide variety of equipment. There is a can alignment device, a rotary liquid dispenser for accurate liquid filling, a valve insertion mechanism, a rotary crimping and gas charging unit that ensures proper sealing and gas filling.

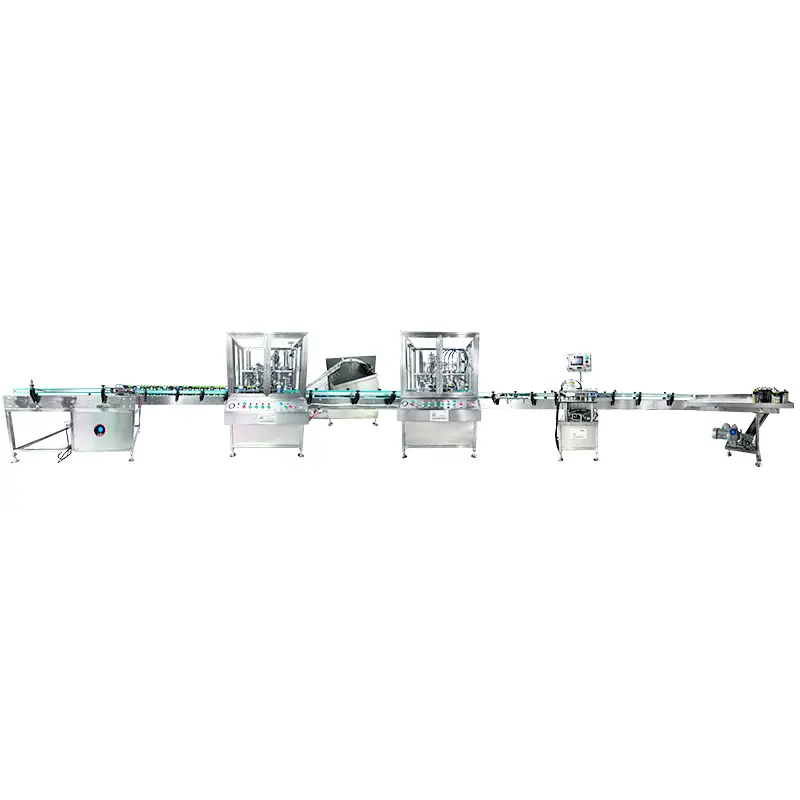

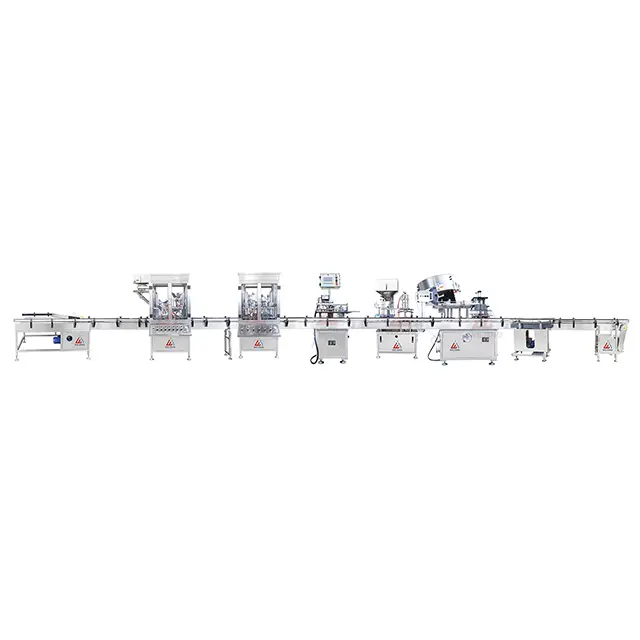

3600 BPH Automatic Aerosol Filling Ma...

This Automatic Aerosol Filling Line is composed of a can detector head, a liquid filling head, an insert valve, a straightening valve, a sealing mechanism, a gas filling head, an actuator fixture, and an inkjet belt. Possessing the attributes of high precision and efficiency, it is capable of dealing with one-inch tinplate and aluminum cans that conform to global standards. It is well-suited for filling medium-viscosity substances such as oils, waters, latexes, solvents, and analogous materials. Moreover, it is appropriate for filling propellants like DME, LPG, R134a, N2, CO2, and so on. Its sphere of application has been extended to the chemical, cosmetics, food, and pharmaceutical industries, fulfilling diverse liquid packaging requirements.

Aerosol Can Filling Sealing Machine

This aerosol production line is capable of yielding 2400 to 3000 cans each hour, possessing the traits of high filling accuracy and remarkable efficiency. The entire line of machinery is furnished with an explosion-proof mechanism, which is suitable for aerosol tanks of diverse diameters as well as various kinds of nozzles and outer covers.

Aerosol Snow Spray Paint Filling Machine

This aerosol manufacturing line is designed for the production of various aerosol items. It can be used to produce snow spray, spray paint, window spray for parties, rust remover and other products that contain internal glass beads or steel beads. Additionally, it is well-suited for the production of body spray, air fresheners, olive oil sprays, shaving sprays and other common aerosol products.