Aerosol Cans Weight Checker Machine

The Fully Automatic Aerosol Weight Checking Machine represents a top - notch solution for accurate and efficient weighing during aerosol production. It's an advanced piece of equipment that utilizes the latest technology and comes with a high - precision weighing mechanism. This enables it to provide precise measurements each time it's used. Renowned as the premier weight - measuring device in the industry, it ensures stable and trustworthy results, fulfilling the strict quality demands of aerosol manufacturing. Moreover, thanks to its built - in checkweigher, this machine makes sure that every aerosol product complies with the set weight criteria, reducing product discrepancies to a minimum and enhancing customer contentment to the fullest.

Electric Aerosol Cans Weight Checker

In the aerosol production line, the high - speed electronic weight checking machine is employed for the online weight inspection of every can. It's an extremely sophisticated device specifically developed for this purpose. This machine makes use of cutting - edge electronic sensing technology to guarantee precise and efficient weight measurement of the cans. Thanks to its high - speed operation, it can swiftly identify any cans that don't fulfill the stipulated weight criteria, thus safeguarding the quality and uniformity of the aerosol products. Utilizing this machine can enhance production efficiency significantly and cut down on waste, making it an essential piece of equipment in modern aerosol production.

Aerosol Cans Safety Cover Fixed Machine

The High-Speed Auto Safety Cover Fixing Equipment is crafted for affixing spray safety covers onto aerosol items. It represents a cutting-edge and highly proficient apparatus custom-made for this specific task. With extraordinary velocity and pinpoint accuracy, it guarantees the firm and dependable fixing of safety covers. This outstanding machine remarkably amplifies production efficiency, conserves precious time and workforce expenses, and enables you to fulfill the strictest safety benchmarks. Opt for our top-of-the-line machinery now and relish the advantages of augmented productivity and elevated customer contentment.

Auto Can Feeding Machine Aerosols

Full automatic can feeding machine for aerosol spray cans is highly efficient. It can accurately feed cans, reducing manual operation. With advanced technology, it ensures smooth running, improving production efficiency and is widely used in the aerosol can production line.

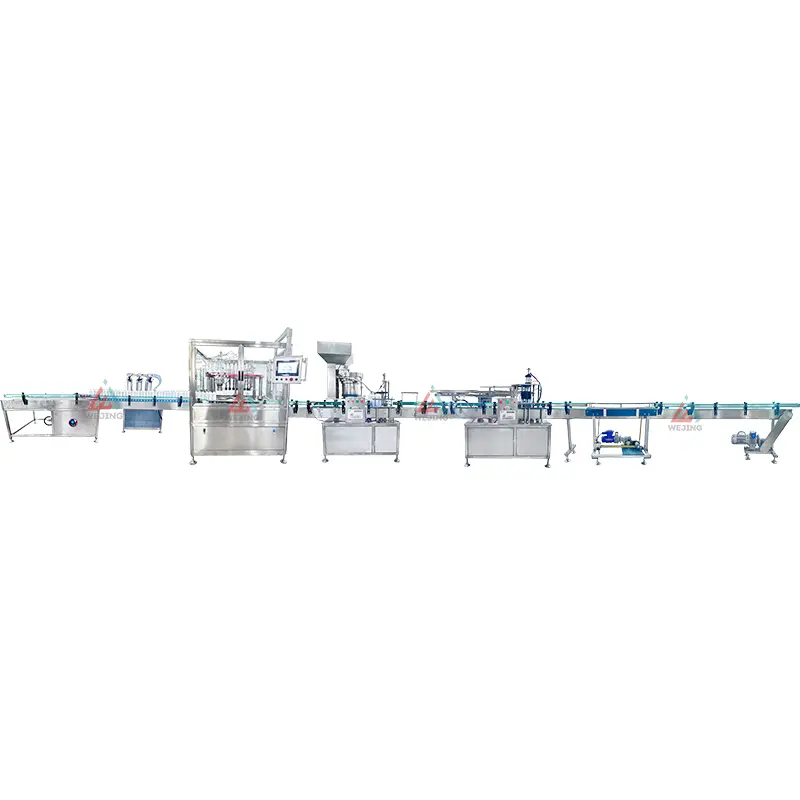

Spray Paint Can Management Machine

The Fully Automatic Management Machine for Aerosol Bottle is an advanced solution custom - made for the efficient production and management of diverse aerosol products. Stepless transmission is adopted to modify the rotational speed of the motor, enabling the rollers of the conveyor belt to achieve any rotational speed. Users are able to adjust the speed based on their production rate, and the conveyor belt can pull the bottles to fulfill the automatic bottle - conveying function.

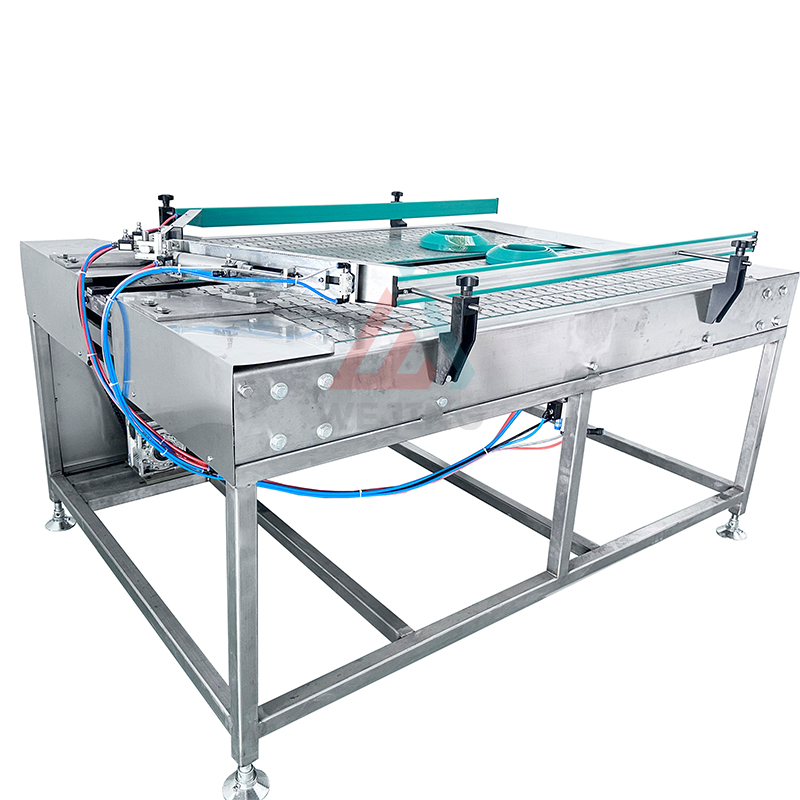

Aerosol Water Bath Detecting Machine

Water Bath Detection Equipment within the Aerosol Filling Production Chain is an essential apparatus crafted to uphold the caliber and security of aerosol merchandise. The aerosol container gets automatically gripped and inserted into the water reservoir by the primary unit for uninterrupted water bath scrutiny. This inspection vat is custom-built for spray paint filling systems and aerosol dispensers. It utilizes a water bath mechanism to spot any seepages or imperfections in the aerosol cans, ascertaining that merely leak-proof and dependable items are dispatched. Thanks to its precise detection proficiency, this vat fortifies the comprehensive quality management procedure and instills confidence in both producers and end-users.

Aerosol Can Capping Machine

For any automatic aerosol assembly line, the High Speed Automatic Aerosol Spray Can Capping Machine is a vital piece of equipment. This cutting - edge machine is crafted to cap aerosol cans at a high speed, thus guaranteeing supreme efficiency and productivity. It is equipped with advanced technology and a user - friendly interface, which facilitates easy operation and maintenance. Thanks to its high - performance and reliability, this capping machine is the perfect option for any aerosol production plant aiming to enhance their operations and boost their output.

Auto Aerosol Can Capper Machine

High - Speed Capping Machine is an outstanding solution for capping aerosol bottles. This automatic capper is custom - made for aerosol filling lines, providing remarkable speed and efficiency. Its high - speed functions enable fast and precise capping, maximizing production. Advanced technology ensures caps are firmly fixed, avoiding leakage and safeguarding product quality. The user - friendly design and easy integration with current production lines make it invaluable in aerosol manufacturing. Rely on our machine to simplify production and achieve excellent outcomes.

High Speed Aerosol Actuator Fixed Mac...

The High - speed auto actuator fixed machine is utilized for installing spraactuators in aerosol products. It's an advanced piece of equipment designed to install spraactuators in aerosol products both efficiently and accurately. This top - of - the - line machine integrates high - speed operation with precise control, providing an outstanding installation experience to meet the requirements of your aerosol production.

3 in 1 Semi Auto Aerosol Machine

A semi-automatic aerosol liquid filling machine is a device that fills liquid materials into aerosol cans, commonly used for small-scale production of aerosol products.

4-in-1 Aerosol Filling Machine

Semi-automatic 4-in-1 aerosol filling machine integrates four functions: liquid filling, valve alignment, curling sealing, and gas filling. Accurately control the amount during liquid filling to ensure accuracy. Valve alignment ensures accurate installation and lays the foundation for subsequent processes. Curled seal with good sealing to prevent leakage. Gas filling meets specific requirements. The operation is relatively convenient, the design is reasonable and easy to learn, and it can be operated after simple training. Using high-quality materials and advanced technology, it has high stability, strong reliability, stable long-term operation, reduces the probability of failure, and provides strong support for enterprise production. It is a trustworthy equipment.

4 in 1 Aerosol Filling Crimping Machine

Semi - automatic 4 - in - 1 aerosol filling machine encompasses four functions within one: liquid filling, valve alignment, curling sealing, and gas filling. When it comes to liquid filling, the quantity is controlled with such precision that accuracy is fully ensured. The valve alignment function makes sure the valves are installed precisely, setting a solid foundation for the following procedures. The curling seal has remarkable sealing performance, effectively preventing any leakage. Gas filling satisfies specific requirements without fail. This machine is relatively easy to operate. Its design is not only reasonable but also intuitive, allowing operators to quickly grasp the operation process even after just a simple training session. Constructed with top - quality materials and advanced technology, it boasts high stability and strong reliability. It can run smoothly over long periods, significantly reducing the probability of malfunction. This provides robust support for the production activities of enterprises, making it a highly trustworthy piece of equipment.