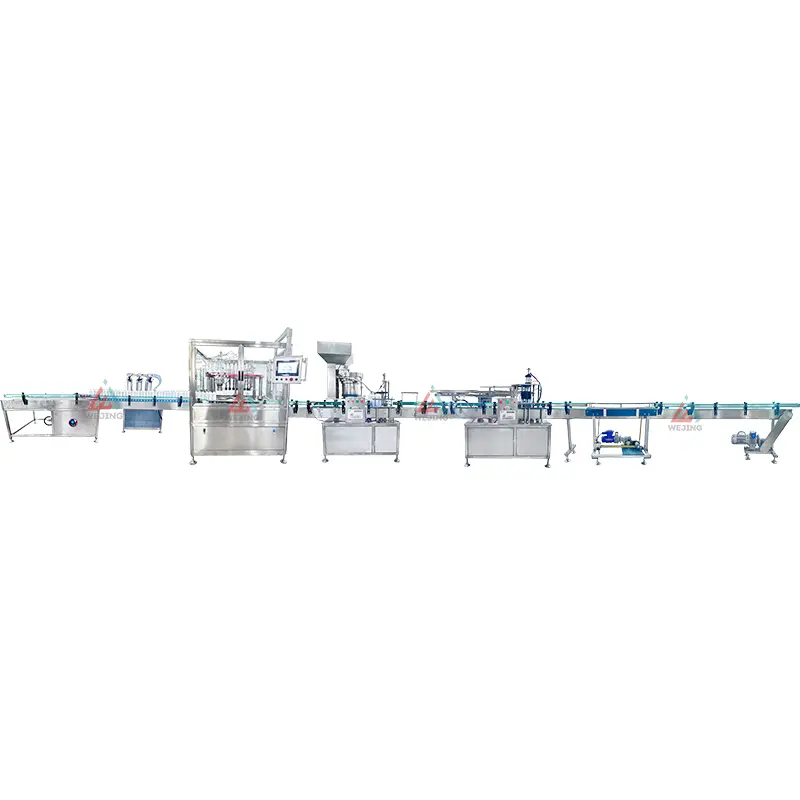

Auto Bag On Valve Aerosol Filling Line

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Filling capacity (cans/min) |

45-60cans/min |

|

Liquid filling volume (ml) |

10-300ml/head |

|

Gas filling accuracy |

≤±1% |

|

Liquid filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35-70 ( can be customized) |

|

Applicable cans height (mm) |

70-300 ( can be customized) |

|

Applicable valve (mm) |

25.4 (1 inch) |

|

Propellant |

N2, compressed air |

|

Max gas consumption (m3/min) |

6m3/min |

|

Power (KW) |

AC 380V/50HZ |

|

Air source |

0.6-0.7Mpa |

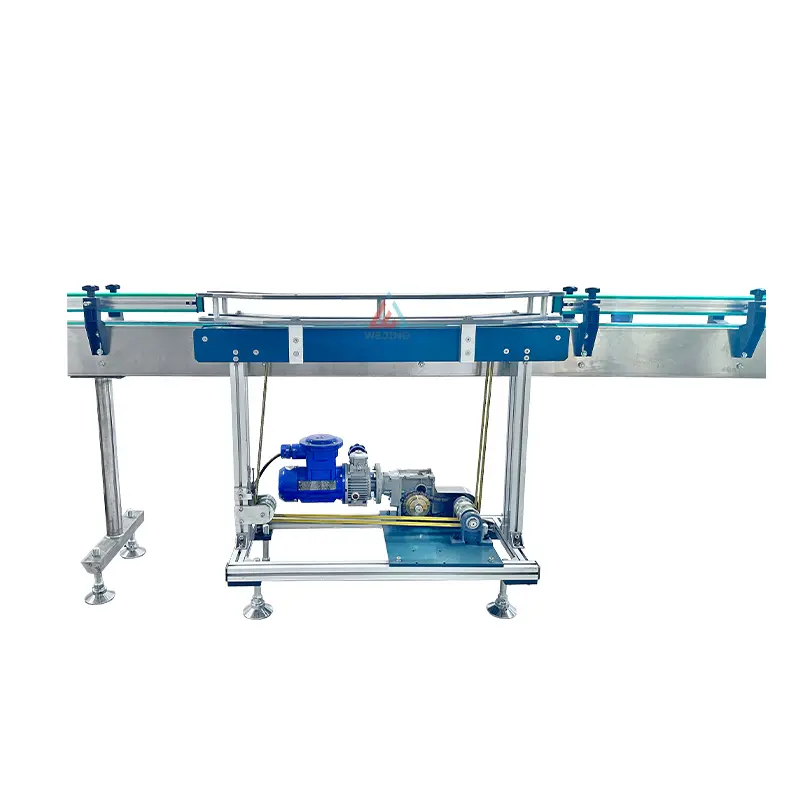

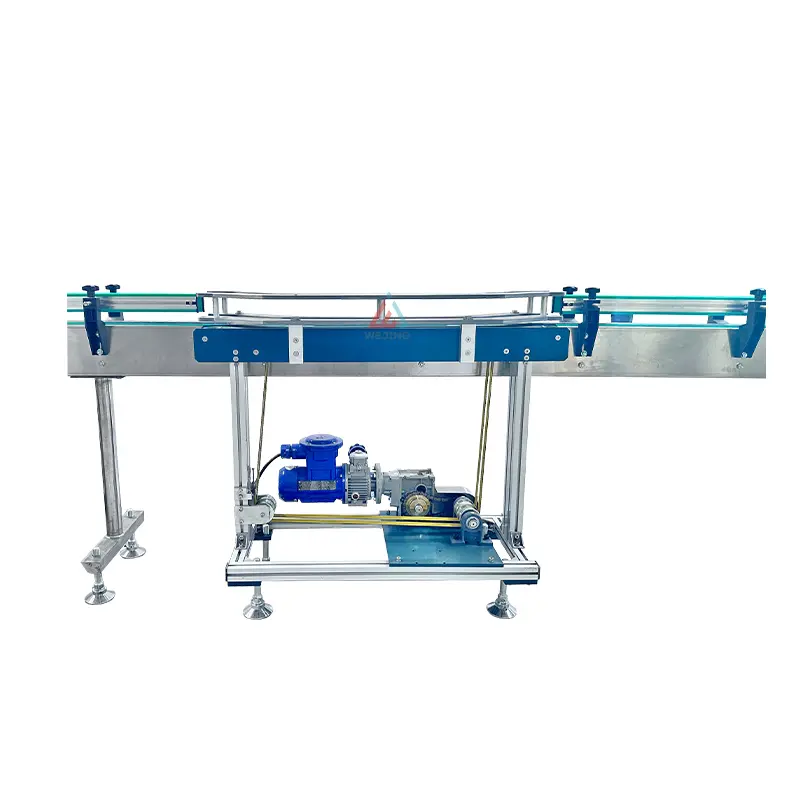

Can Feeding Machine

Ensure that the cans are supplied in a correct and organized manner along the conveyor belt.

Machine filling system

Fill the aerosol canister with propellant gas and then seal it. This process enables the substances inside the canister and the propellant to blend, ultimately creating an aerosol. The key steps involved are as follows:

1. Compress and fill the gas.

2. Fill in the liquid.

3. Measure the pressure.

4. Carry out cleaning.

Actuator Fixed Machine

Attach the spray nozzle firmly to the bottle's valve, allowing users to effortlessly dispense the liquid in a fine mist spray pattern.

Capping Machine

Putting an outer casing on aerosol products serves to safeguard the valve, the nozzle as well as the main body of the container. It acts as a shield, preventing potential damage to these crucial components during handling, storage, or transportation. This way, the integrity and functionality of the aerosol products can be maintained, ensuring they work properly when needed.

Inkjet Belt

Execute spray-painting operations to imprint essential details like the production date, batch number, and expiration date onto the bottles or packaging of aerosol items. This practice streamlines the process of product tracking and management, ensuring efficient oversight throughout the product lifecycle.PRODUCT Advantages

1. Unrivalled Precision: The machine fills aerosol spray cans with remarkable exactitude. It minimizes product wastage and ensures each can is filled uniformly, maintaining an identical level.

2. High-speed and Efficient: Within a brief period, it can process a vast quantity of cans, substantially boosting production volume.

3. Exceptionally Reliable: Incorporating state-of-the-art technology, it operates smoothly, significantly reducing the likelihood of malfunctions and failures.

4. Superior Filling Standard: It guarantees the optimal filling of the bag-on-valve system, preserving the product's quality and integrity throughout.

2. High-speed and Efficient: Within a brief period, it can process a vast quantity of cans, substantially boosting production volume.

3. Exceptionally Reliable: Incorporating state-of-the-art technology, it operates smoothly, significantly reducing the likelihood of malfunctions and failures.

4. Superior Filling Standard: It guarantees the optimal filling of the bag-on-valve system, preserving the product's quality and integrity throughout.

5. Industry-aligned: Purposefully designed to fulfil all the specific demands of the aerosol spray can filling procedure within the industry.

PRODUCT Applications

1. Medical: Fills aerosol cans with sterile saline accurately for healthcare, protecting patients.

2. Nasal Care: Packs nasal cleanser, offers smooth spray for user comfort and better care.

3. Food: Ideal for edible oil spray cans, ensures quality spray for consumers.

4. Fire Fighting: Fills water-based fire extinguishers, maintains stability and efficiency.

5. Household Cleaning: Fills various aerosol cleaners, boosts production for cleaner homes.

2. Nasal Care: Packs nasal cleanser, offers smooth spray for user comfort and better care.

3. Food: Ideal for edible oil spray cans, ensures quality spray for consumers.

4. Fire Fighting: Fills water-based fire extinguishers, maintains stability and efficiency.

5. Household Cleaning: Fills various aerosol cleaners, boosts production for cleaner homes.