Automatic Aerosol Actuator Fixed Machine

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Capacity |

50-70cans/min |

|

Power |

No |

|

Pressure |

≥0.5Mpa |

|

Air consumption |

≥0.2m³/min |

|

Suitable can diameter/height |

φ35-φ70mm/100-300mm |

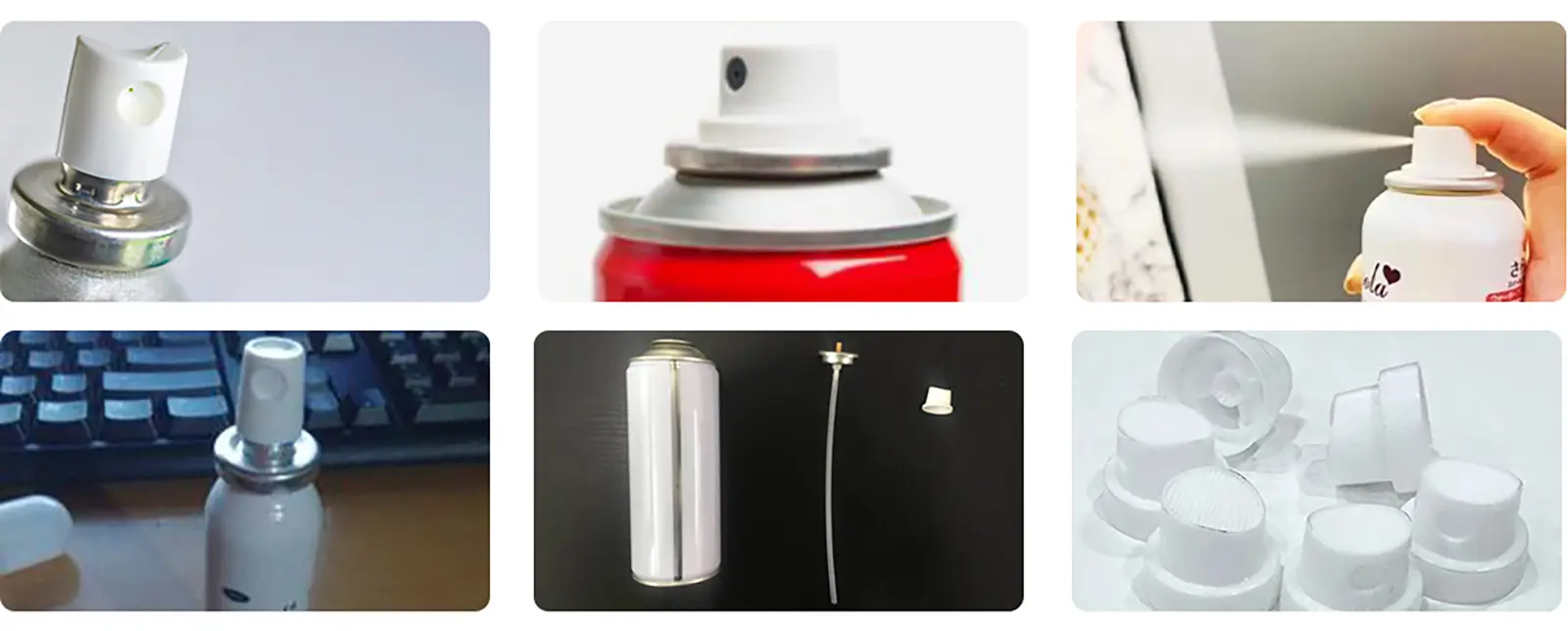

product Applications

1. Suitable for nozzle pressing of beauty and personal care products (such as hair gel, etc.).

2. Commonly used for nozzle pressing in the manufacture of aerosol household cleaning agents to ensure sealing.

3. Used for nozzle pressing of aerosol vehicles and industrial products (such as lubricants, etc.).

4. Used for nozzle compression in aerosol insecticide manufacturing to ensure sealing.

5. Used for nozzle pressing in aerosol paint and coating production to ensure sealing.

2. Commonly used for nozzle pressing in the manufacture of aerosol household cleaning agents to ensure sealing.

3. Used for nozzle pressing of aerosol vehicles and industrial products (such as lubricants, etc.).

4. Used for nozzle compression in aerosol insecticide manufacturing to ensure sealing.

5. Used for nozzle pressing in aerosol paint and coating production to ensure sealing.

product faq

Q: Can this machine handle aerosol cans of diverse sizes and shapes?

Q: Is the machine compatible with distinct types of aerosol products, like flammable or corrosive ones?

Q: How straightforward is it to change the settings for different aerosol products?

Q: Can the machine detect and reject cans with faulty or incomplete nozzle pressing?

Q: What kind of maintenance is required for the machine?

A: Regular maintenance involves cleaning the machine, inspecting and replacing worn parts, and ensuring proper lubrication. For specific maintenance guidelines, please refer to the manufacturer's manual.

A: Indeed, this machine is engineered to deal with aerosol cans of various sizes and shapes, offering flexibility for different product demands.

A: Yes, this machine is designed to handle various kinds of aerosol products, including flammable, corrosive, and non-flammable items, ensuring safe and efficient nozzle suppression.

A: The machine features a user-friendly interface that enables operators to easily modify settings for different aerosol products, including nozzle pressure and speed.

A: Yes, the machine is equipped with sensors to identify nozzle pressing defects or incompleteness. It can automatically reject such cans to ensure that only products with proper sealing can continue on the filling line.

A: Regular maintenance involves cleaning the machine, inspecting and replacing worn parts, and ensuring proper lubrication. For specific maintenance guidelines, please refer to the manufacturer's manual.