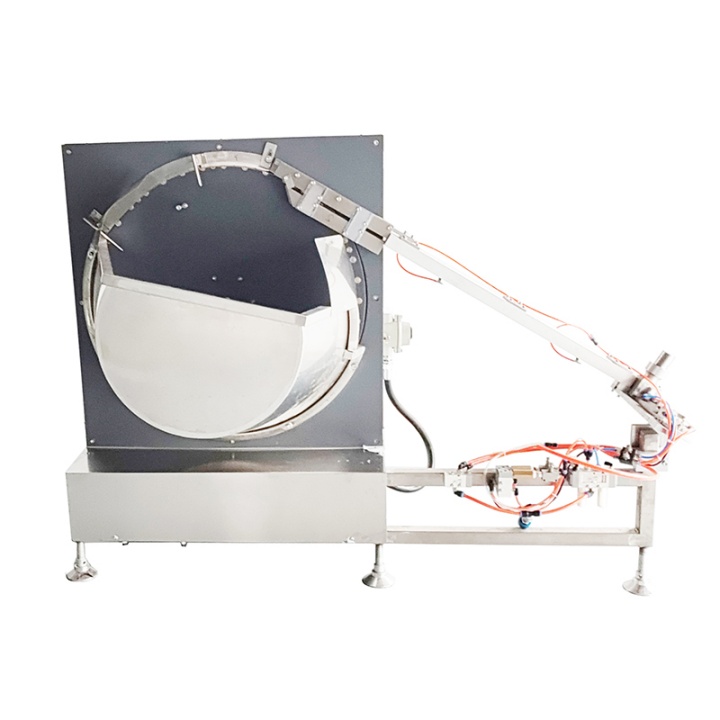

Automatic Aerosol Valve Inserted Machine

1. Exceptional Automation Level: The process of valve insertion is entirely automated, which diminishes the dependence on manual work and boosts the productivity of the production line.

2. Exactitude and Uniformity: It guarantees precise and steady valve insertion, thereby leading to the creation of top-notch aerosol items.

3. Adaptable Customization: It has the capacity to be tailored and adjusted to fit diverse production lines and particular demands.

4. Enhanced Productivity Rate: It allows for rapid valve insertion, optimizing the production volume and fulfilling the requirements of the market.

5. Dependability and Longevity: Constructed with premium parts, it is engineered for durability and reliable functioning during uninterrupted operation.

2. Exactitude and Uniformity: It guarantees precise and steady valve insertion, thereby leading to the creation of top-notch aerosol items.

3. Adaptable Customization: It has the capacity to be tailored and adjusted to fit diverse production lines and particular demands.

4. Enhanced Productivity Rate: It allows for rapid valve insertion, optimizing the production volume and fulfilling the requirements of the market.

5. Dependability and Longevity: Constructed with premium parts, it is engineered for durability and reliable functioning during uninterrupted operation.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Applicable valve |

1inch |

|

Filling speed |

60-70cans/min |

|

Power |

AC380V 0.37KW |

|

Material |

SS304 |

Product Applications

1. Automated valve placement within aerosol filling setups.

2. Boosting production efficacy and cutting down on workforce expenses.

3. Securing accurate and steady valve insertion operations.

4. Appropriate for various valve varieties and dimensions.

5. Harmonious with completely automated aerosol filling line arrangements.

2. Boosting production efficacy and cutting down on workforce expenses.

3. Securing accurate and steady valve insertion operations.

4. Appropriate for various valve varieties and dimensions.

5. Harmonious with completely automated aerosol filling line arrangements.

Operate Guide

1. Get the aerosol cans and valves ready.

2. Place the cans onto the conveyor belt or the feeding mechanism.

3. Adjust the parameters and operating mode via the control panel.

4. Initiate the machine and keep an eye on the valve insertion progress.

5. Frequently inspect and service the machine to ensure top-notch performance.

2. Place the cans onto the conveyor belt or the feeding mechanism.

3. Adjust the parameters and operating mode via the control panel.

4. Initiate the machine and keep an eye on the valve insertion progress.

5. Frequently inspect and service the machine to ensure top-notch performance.