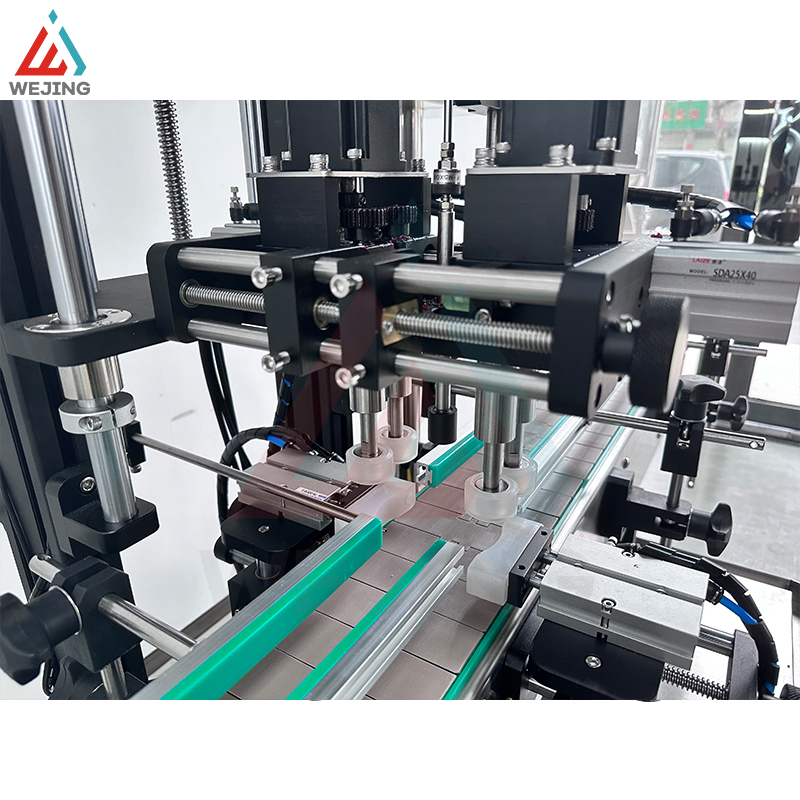

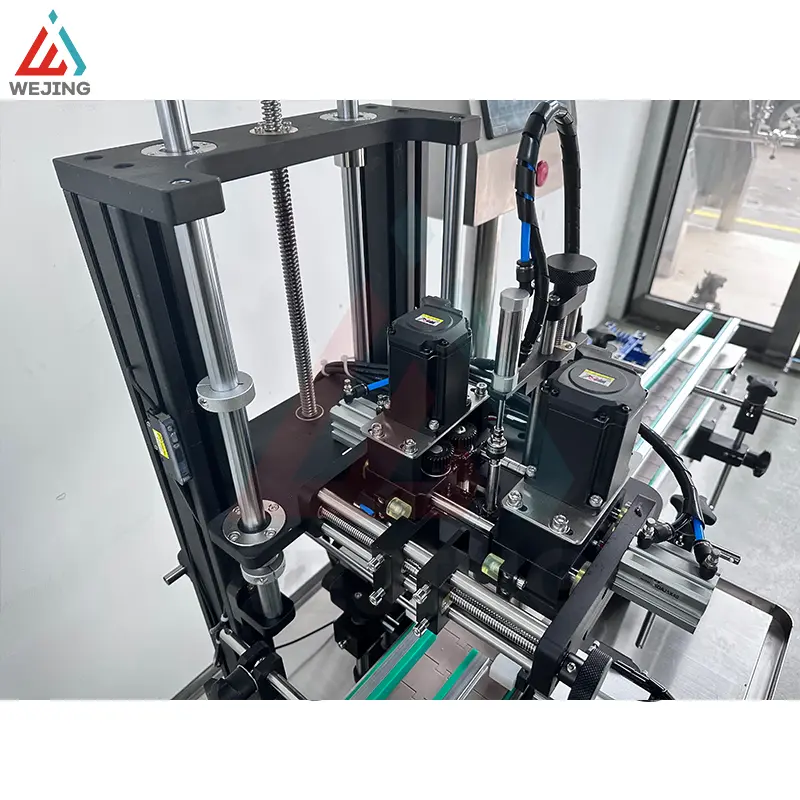

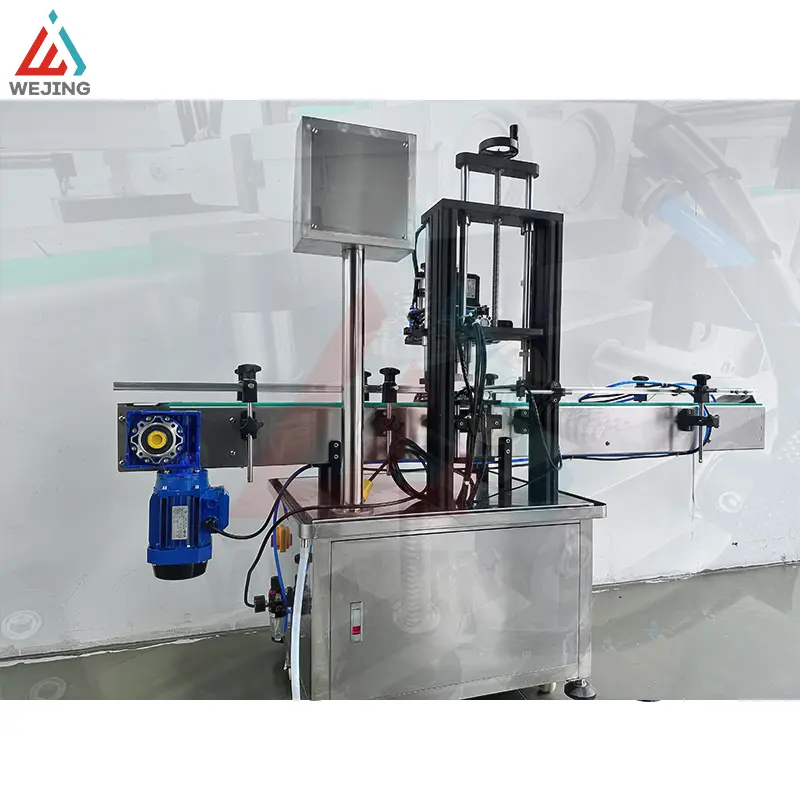

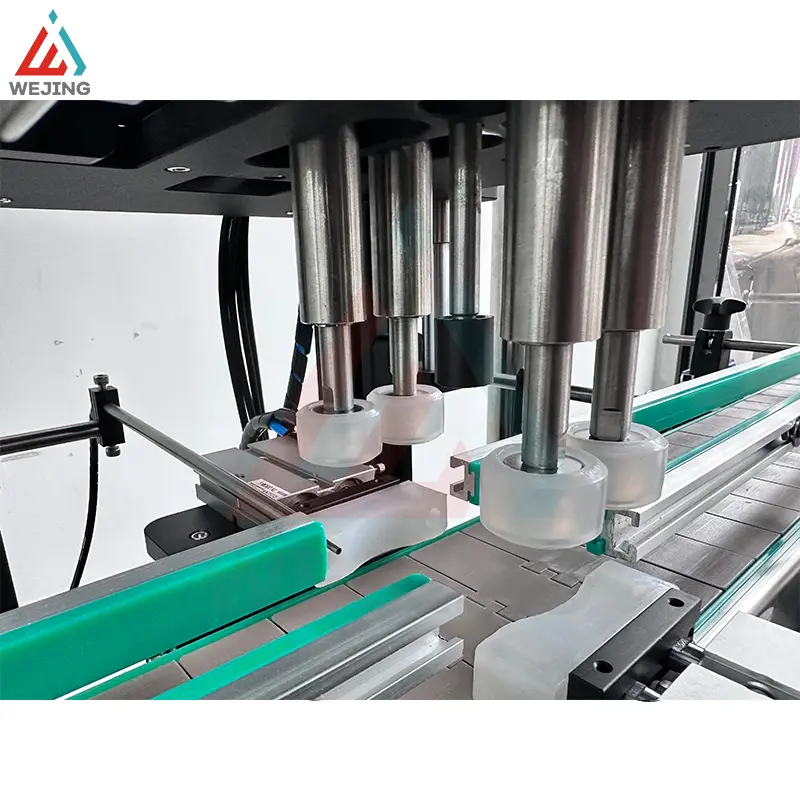

Automatic Servo Capping Machine

Capping and Labeling MachinePRODUCT PARAMETERS

|

Voltage |

AC220V 50Hz |

|

|

Power |

1500W |

|

|

Size |

2500mm*800mm*1450mm |

|

|

Net weight |

About 95 kilograms |

|

|

Air pressure |

0.4-0.6MPa |

|

|

Various lock covers |

18mm-50mm |

|

|

Bottle locking range |

Bottle height 80-300 mm |

Bottle width 20-120 mm |

|

Lock cover speed |

20-80 pieces/minute |

|

|

Lock cover torque |

The standard value is approximately 0-1.26 N.m |

|

|

Sealing power |

2*400W |

|

|

Sealing method |

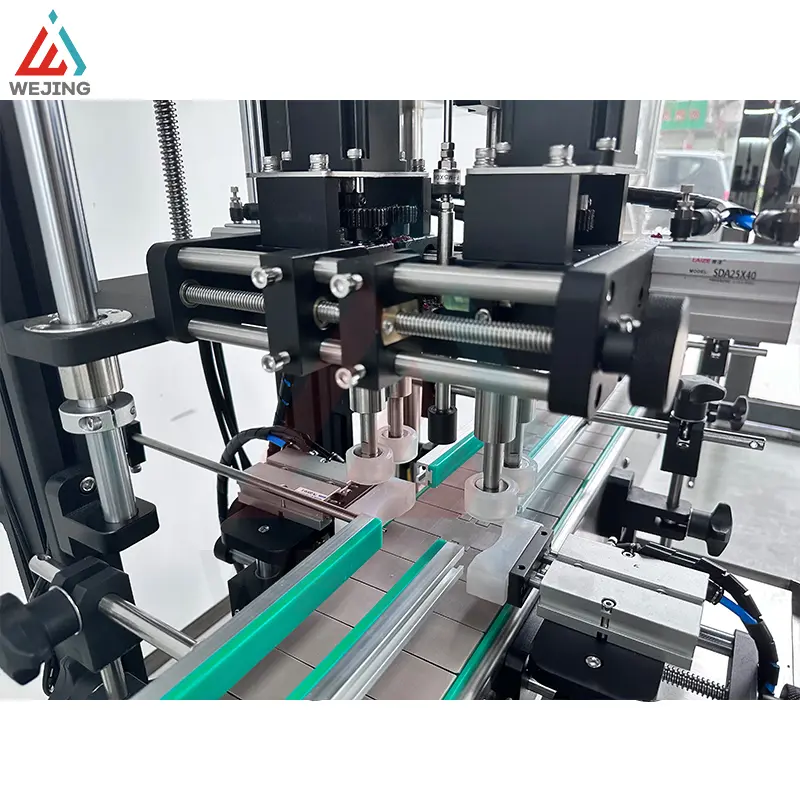

Servo mechanism torque adjustment time |

|

|

Timing belt motor |

86 Step 12N.m*2 |

|

|

Synchronize the clamping distance |

800mm |

|

|

Belt speed |

0-28m/min |

|

|

Applicable types |

Circular plastic and metal covers, pump head covers, duck covers, etc. |

|

01

7 Jan 2019

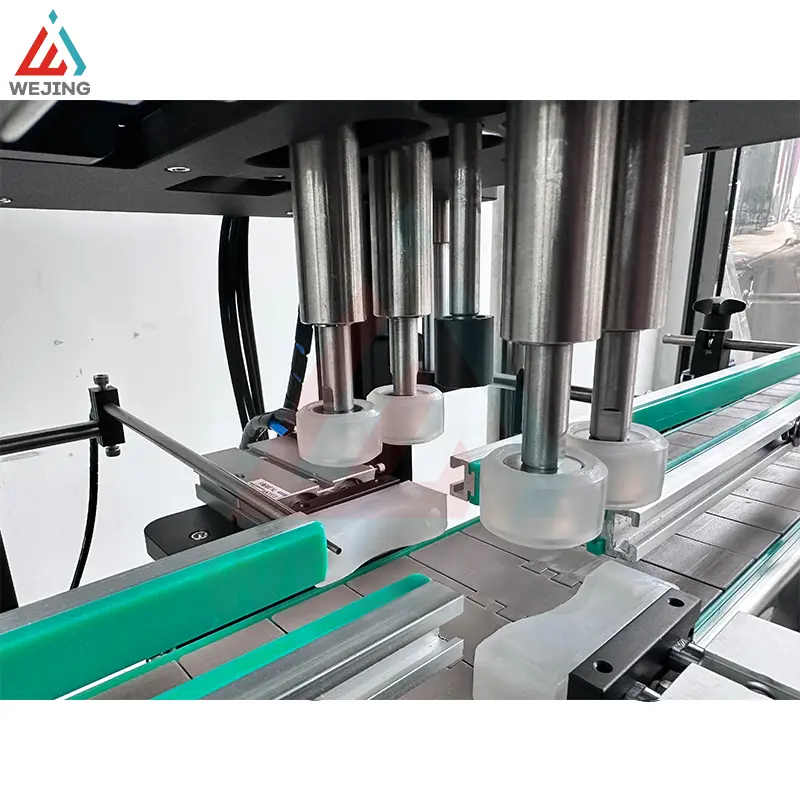

1. Suitable for locking covers of pump heads, platypus, round caps and other products.

02

7 Jan 2019

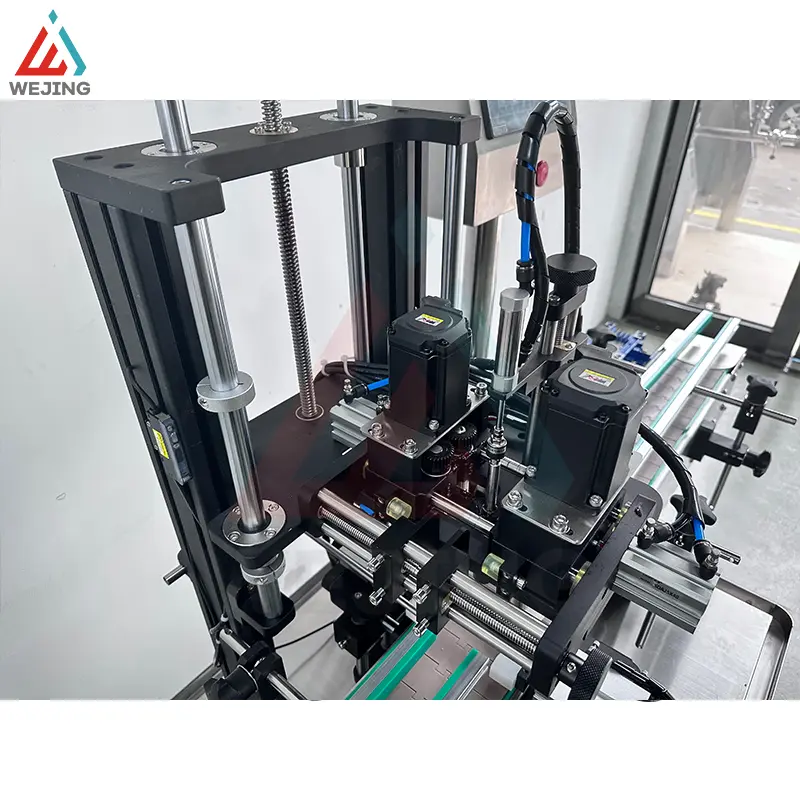

2. The overall design is reasonable, practical and durable, easy to operate, and does not require tools to adjust the bottle height.

02

7 Jan 2019

3. Synchronize the lid with the bottle clamp to prevent the bottle from overflowing.

02

7 Jan 2019

4. The torque setting for the lock cover is simple and reliable.

5. Suitable for various packaging materials.

5. Suitable for various packaging materials.

Product Applications

The automatic servo capping machine can be applied to a variety of products with caps. For example, sauce bottles and beverage caps in the food industry; Pharmaceutical industry drug caps; Lotion bottles, cream bottles and other types of plastic caps for the cosmetics industry.