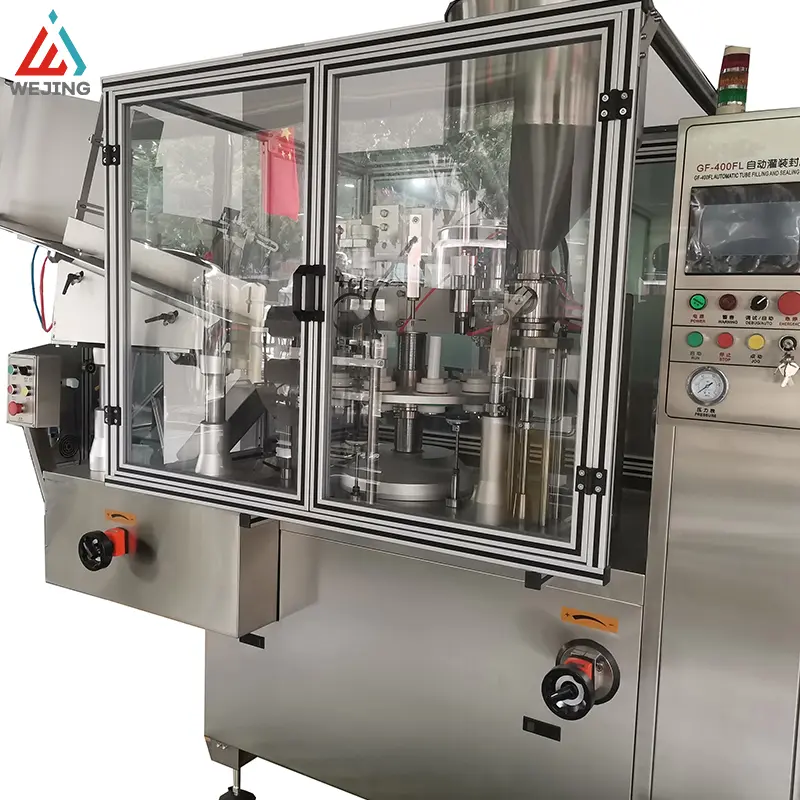

Automatic Tube Filling Sealing Machine

Tube Filling Sealing MachinePRODUCT PARAMETERS

|

Tube Filling and Sealing Machine( WJ—400F) |

||

|

Tube material |

Metal pipe, aluminum pipe |

|

|

Tube diameter |

φ10—φ50 |

|

|

Tube length |

60—250(Customizable) |

|

|

filling volume |

5—400ml/pc(Adjustable) |

|

|

Filling Precision |

≤±1% |

|

|

Production capacity (pcs/min) |

30—50(Adjustable) |

|

|

Working air pressure |

0.55—0.65mpa |

|

|

Motor power |

2kw(380V/220V 50Hz) |

|

|

Heat seal power |

3kw |

|

|

Overall dimension |

2620×1020×1980 |

|

|

Weight of main engine |

1100 |

|

1. High quality nighttime crystal display combines controller and button programming with video screen operation, comprehensively understanding the smooth speed regulation, parameter setting, output statistics, air pressure display, fault display and other working conditions of the equipment, making control simple and user-friendly.

3. The high-precision alignment system reduces the color difference range between the casing and the color code.

5. Integration of mechanical, optical, electrical, and pneumatic components to achieve automatic display (alarm) when pipes are not filled, pipes are not in place, air pressure is low; Fully automatic functions such as automatic closing when opening the protective door.

Working Principle

1. The fully automatic filling and sealing machine is specially designed and made for filling and sealing plastic composite pipes in various industries like cosmetics, pharmaceuticals, food, and adhesives.

- Its basic working process starts with inserting the tubes in the loading groove vertically into the first loading mold one by one.

2. Then, the tubes are rotated by a rotating disk and moved to the second working position for detection and alignment.

3. At the third working position, nitrogen is injected into the tubes.

4. In the fourth position, the required material is filled into the tubes.

- After that, the tubes are sent to multiple stations including heating, bending, extrusion, printing room, cooling, cutting, etc.

5. Finally, the tubes reach the twelfth station where the finished products are exported. Each pipe has to undergo this series of processes for proper filling and sealing.

6. The main structure of this machine includes a main transmission mechanism, a feeding mechanism, a rotating mechanism, a sealing mechanism, a filling mechanism, and an electrical control system.

- Its basic working process starts with inserting the tubes in the loading groove vertically into the first loading mold one by one.

2. Then, the tubes are rotated by a rotating disk and moved to the second working position for detection and alignment.

3. At the third working position, nitrogen is injected into the tubes.

4. In the fourth position, the required material is filled into the tubes.

- After that, the tubes are sent to multiple stations including heating, bending, extrusion, printing room, cooling, cutting, etc.

5. Finally, the tubes reach the twelfth station where the finished products are exported. Each pipe has to undergo this series of processes for proper filling and sealing.

6. The main structure of this machine includes a main transmission mechanism, a feeding mechanism, a rotating mechanism, a sealing mechanism, a filling mechanism, and an electrical control system.

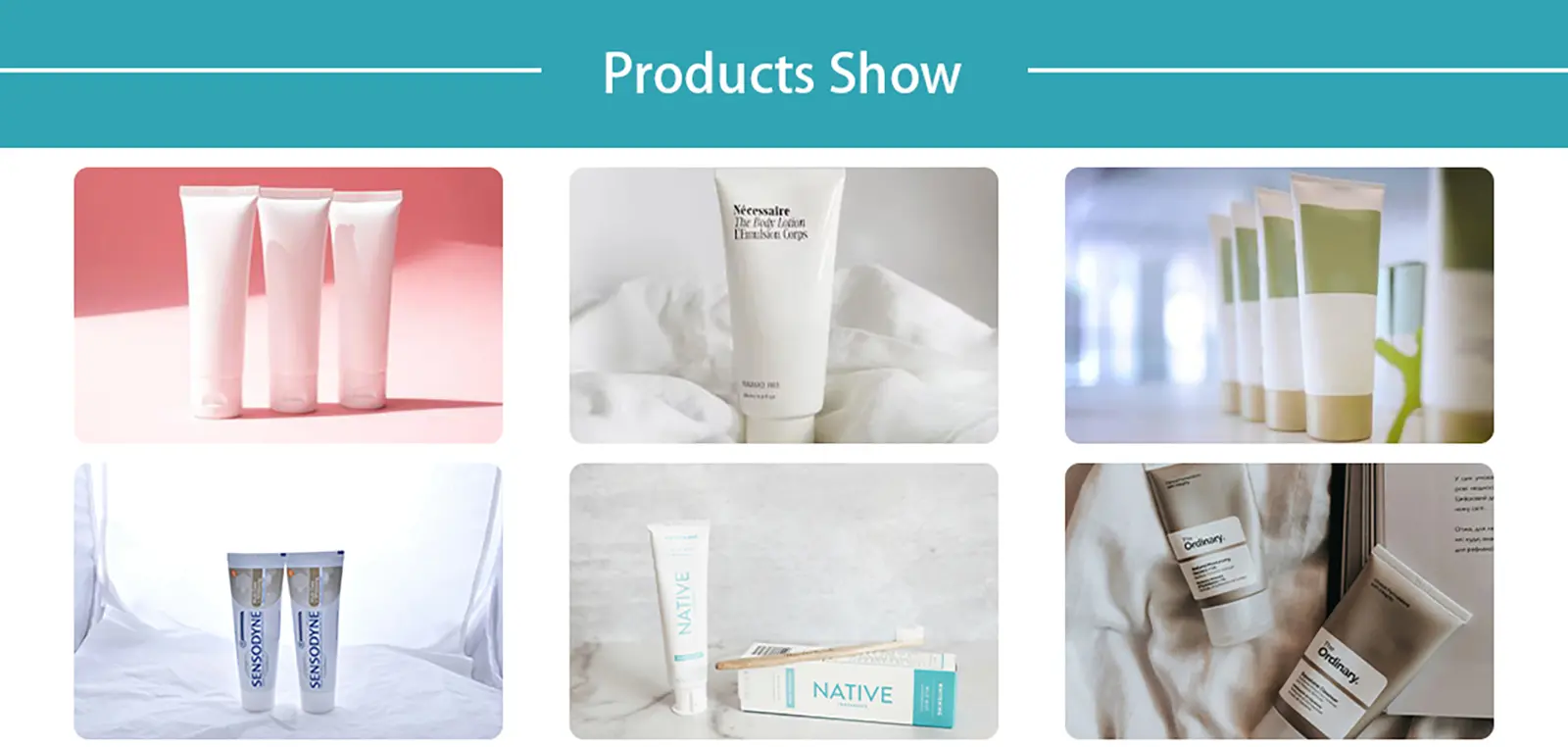

Product Applications

The fully automatic filling and sealing machine is an efficient packaging equipment. It combines filling and sealing functions on one machine, which can automatically complete various flexible tube packaging operations. This device adopts advanced technology to ensure filling accuracy, and the tail seal is durable and beautiful. Widely used in industries such as cosmetics, pharmaceuticals, and food, it has improved production efficiency, reduced labor costs, and brought huge economic benefits to enterprises.