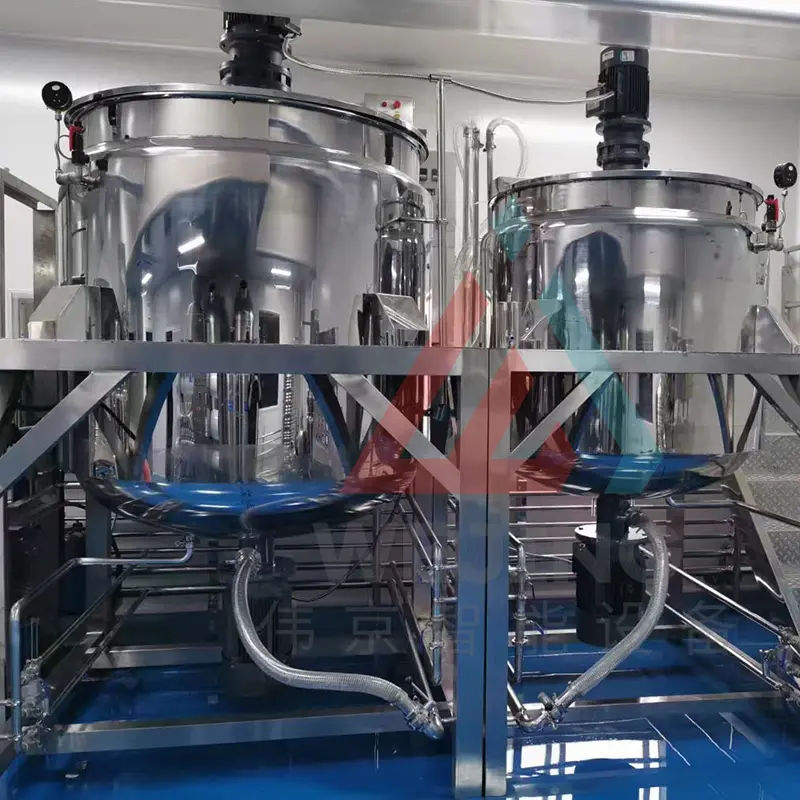

Blending Mixing Tank with Agitator

Mixing Tank With AgitatorPRODUCT PARAMETERS

|

Model |

Capacity (L) |

Mixing |

Homogenization |

||

|

Power (kW) |

Speed (RPM) |

Power (kW) |

Speed (RPM) |

||

|

WJ-M50 |

50 |

0.55 |

0-60 |

1.5 |

0-3000 |

|

WJ-M100 |

100 |

0.75 |

0-60 |

1.5 |

0-3000 |

|

WJ-M200 |

200 |

1.5 |

0-60 |

3 |

0-3000 |

|

WJ-M300 |

300 |

2.2 |

0-60 |

4 |

0-3000 |

|

WJ-M500 |

500 |

2.2 |

0-60 |

5.5 |

0-3000 |

|

WJ-M1000 |

1000 |

4 |

0-60 |

11 |

0-3000 |

|

WJ-M2000 |

2000 |

5.5 |

0-60 |

15 |

0-3000 |

|

WJ-M3000 |

3000 |

7.5 |

0-50 |

18.5 |

0-3000 |

|

WJ-M5000 |

5000 |

11 |

0-50 |

22 |

0-3000 |

Mixing

The material is completely stirred in the container by the rotation of the mixer. Blenders are usually driven by motors, and the speed and mixing method can be adjusted as needed.

Cutting

Blenders in uniform mixers usually have special designs such as blades and impellers. D. Shear force can be generated on the material. This shear force can destroy material particles and make them smaller.

Dispersion

During the mixing and shearing process, the material particles gradually disperse and are evenly distributed throughout the entire system.

Heating and cooling system

steam or electric heating, circulating water or coolant cooling.

Homogenization

Through continuous mixing, shearing, and dispersion, the material particles gradually become smaller and more evenly distributed, thereby achieving homogenization effect.

Product Advantages

1. Efficient homogenization: It can achieve the ideal state of material particles, greatly improving product quality and stability.

2. Precise control: The stirring speed and time can be precisely adjusted according to the processing needs of different materials.

3. Easy to operate: Humanized design, easy to operate, reducing labor costs and learning time.

4. Widely applicable: Suitable for industries such as food, chemical, pharmaceutical, etc., with strong universality.

5. Durable and reliable: The equipment has a sturdy structure, reliable quality, and long service life.

6. Support personalized services.

2. Precise control: The stirring speed and time can be precisely adjusted according to the processing needs of different materials.

3. Easy to operate: Humanized design, easy to operate, reducing labor costs and learning time.

4. Widely applicable: Suitable for industries such as food, chemical, pharmaceutical, etc., with strong universality.

5. Durable and reliable: The equipment has a sturdy structure, reliable quality, and long service life.

6. Support personalized services.

Product Applications

The uniform mixer for liquid detergent has extensive applications.

For the daily chemical industry, it can be used in the manufacturing of a variety of liquid detergents, such as those for laundry, dishwashing, as well as shampoos and shower gels.

It is applicable in the cosmetics industry, serving in the production of lotions, creams, toners, and other products within this field.

In the pharmaceutical industry, this mixer can be used for the production of liquid preparations including oral liquids and lotions.

For the daily chemical industry, it can be used in the manufacturing of a variety of liquid detergents, such as those for laundry, dishwashing, as well as shampoos and shower gels.

It is applicable in the cosmetics industry, serving in the production of lotions, creams, toners, and other products within this field.

In the pharmaceutical industry, this mixer can be used for the production of liquid preparations including oral liquids and lotions.