When it comes to industrial processing, the choice of mixing vessels can drastically impact the quality and efficiency of production. As we look forward to 2025, understanding the various types of Stainless Steel Mixing Vessels becomes crucial for businesses seeking to enhance their operations. Expert in the field, Dr. Emily Carter, notes, "Selecting the right Stainless Steel Mixing Vessel is essential not just for operational efficiency but also for ensuring product integrity and safety." Her experience sheds light on how these vessels serve a wide range of industries, from pharmaceuticals to food processing, making them a vital resource.

In this exploration of the top Stainless Steel Mixing Vessel types for your business needs, we will delve into the innovative designs and functionalities available on the market. The versatility and durability of stainless steel make it the preferred choice for manufacturers, ensuring longevity and resilience against corrosive materials. As we analyze the best options for 2025, it’s essential to consider both the specific application requirements and trends shaping the future of mixing technology. This insight will empower businesses to make informed decisions, optimizing their mix operations to meet ever-evolving industry demands.

Stainless steel mixing vessels are essential tools in various industries, including food and beverage, pharmaceuticals, and chemicals. These vessels are designed to blend, mix, and homogenize different products effectively, making them invaluable for achieving consistent quality in production. Their durable nature, resistance to corrosion, and easy maintenance make them a preferred choice for many businesses. Different types of stainless steel mixing vessels can cater to specific applications, with each type designed for particular processes such as batch mixing, continuous mixing, or homogenization.

When selecting a stainless steel mixing vessel, it's important to consider factors such as capacity, the viscosity of the materials being mixed, and the required mixing speed. Certain vessels come with features like jacketed designs for temperature control or specialized agitators for achieving desired mixing results.

**Tips:** Always assess the specific needs of your production processes before investing in a mixing vessel. Customizable options may offer a better fit for unique applications. Additionally, regular maintenance and sanitation of your stainless steel vessels are crucial to uphold product quality and compliance with health regulations. Consider scouting for vessels with easy-access cleaning features to ensure efficiency in your operations.

Stainless steel mixing vessels are essential across various industries due to their durability, corrosion resistance, and hygiene.

In the food industry, jacketed mixing vessels are often utilized, allowing for precise temperature control while blending ingredients. This ensures the preservation of flavors and nutrients, making them suitable for processes such as sauces, dairy products, and baked goods. Their thermal properties facilitate heating or cooling, providing flexibility in food preparation and production.

In the food industry, jacketed mixing vessels are often utilized, allowing for precise temperature control while blending ingredients. This ensures the preservation of flavors and nutrients, making them suitable for processes such as sauces, dairy products, and baked goods. Their thermal properties facilitate heating or cooling, providing flexibility in food preparation and production.

In the pharmaceutical sector, high-purity stainless steel mixing vessels are critical for complying with stringent sanitary standards. These vessels are designed to minimize contamination and are often equipped with features like sanitary fittings and easy-to-clean surfaces. They are widely used for the production of vaccines, ointments, and liquid dosage forms, where the integrity of the product is paramount.

Additionally, in the chemical industry, robust and larger capacity mixing vessels are employed to accommodate various reactions, ensuring thorough mixing of raw materials while allowing safe handling of potentially hazardous substances.

Additionally, in the chemical industry, robust and larger capacity mixing vessels are employed to accommodate various reactions, ensuring thorough mixing of raw materials while allowing safe handling of potentially hazardous substances.

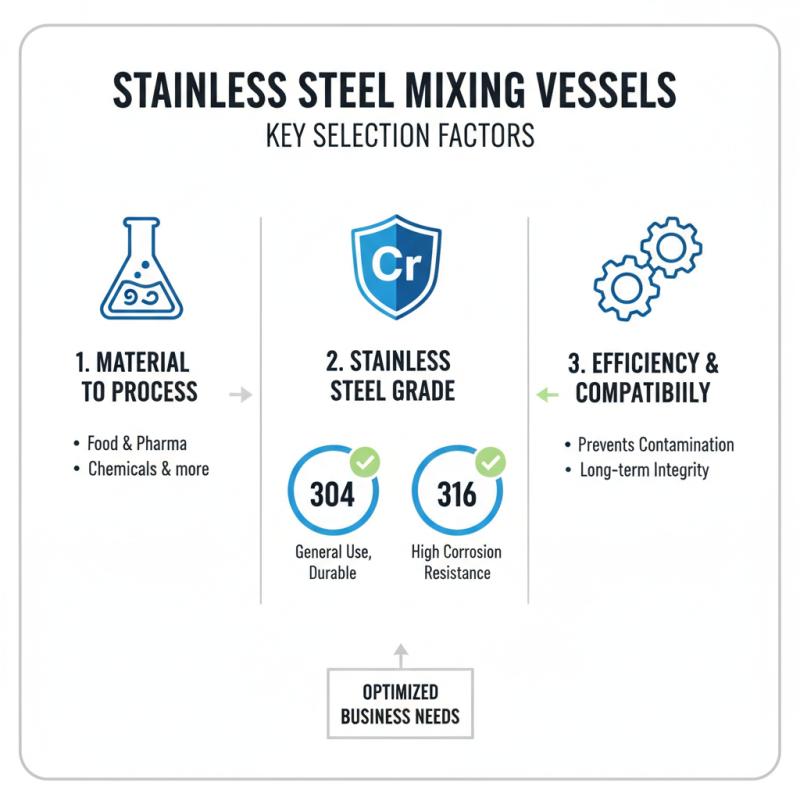

When selecting a stainless steel mixing vessel for your business needs, there are several critical factors to consider that can greatly impact overall efficiency and material compatibility. One of the primary considerations is the type of material the vessel will process. According to industry reports, specific grades of stainless steel, such as 304 and 316, are preferred for their corrosion resistance and durability, particularly in food and pharmaceutical applications. Choosing the right grade ensures that the vessel maintains its integrity over time while minimizing the risk of contamination.

Another essential factor is the vessel design and mixing mechanism. Different mixing applications—such as blending, emulsifying, or dispersing—require specific vessel designs. For instance, report data indicates that vessels with dual-axial or tri-axial agitators provide better mixing and efficiency for viscous materials. Additionally, the vessel size and capacity should align with production scale; a balance is necessary between space efficiency and operational requirements. Understanding these parameters will help businesses optimize their mixing processes and achieve desired outcomes effectively.

Stainless steel has become a preferred material for the manufacturing of mixing vessels across various industries, including food and beverage, pharmaceuticals, and chemical processing. One key benefit of stainless steel is its exceptional resistance to corrosion and rust, allowing it to maintain product integrity in hostile environments. According to a report by the Global Stainless Steel Market, the increasing application of stainless steel in various industrial processes is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is attributable to the unique properties of stainless steel, which not only meet hygiene standards but also extend the lifespan of mixing vessels, ultimately leading to reduced operational costs over time.

In addition to durability, stainless steel mixing vessels offer superior thermal conductivity, which is essential for processes that require precise temperature control. A study conducted by the American Society of Mechanical Engineers emphasizes that stainless steel's ability to efficiently conduct heat allows for uniform mixing and prevents hot spots, thus ensuring consistent product quality. Furthermore, its non-reactive nature ensures that the mixing process does not alter the composition of the materials being processed, which is crucial in industries where product purity is paramount. This makes stainless steel not only a practical choice but also a strategic investment for businesses looking to enhance their operational efficiency and product quality.

| Vessel Type | Capacity (Liters) | Mixing Speed (RPM) | Material Grade | Applications | Benefits |

|---|---|---|---|---|---|

| Agitated Mixing Vessel | 500 | 150 | 316L | Chemical Processing | High durability, corrosion resistance |

| Batch Mixing Vessel | 1000 | 120 | 304 | Food Industry | Easy cleaning, sanitary |

| Tank Mixing Vessel | 2000 | 80 | 316 | Pharmaceuticals | High resistance to rust and chemicals |

| Continuous Mixing Vessel | 1500 | 200 | SUS 304 | Petrochemical | Efficient for large production runs |

| High-Shear Mixing Vessel | 750 | 300 | 316L | Cosmetics | Creates emulsions, fine particle dispersions |

When it comes to maintaining stainless steel mixing vessels, regular upkeep is essential for ensuring their longevity and optimal performance. One of the most critical practices is thorough cleaning. After each use, it is important to wash the vessel with warm, soapy water to remove residues and prevent corrosion. For stubborn stains or deposits, using a mixture of vinegar and baking soda can effectively break down contaminants without damaging the stainless steel surface.

Additionally, periodic inspections play a pivotal role in maintenance. Regularly check for any signs of wear and tear, including scratches or dents that may compromise the vessel's integrity. Promptly addressing minor issues can prevent them from escalating into more significant problems. Furthermore, ensuring that gaskets and seals are in good condition will help maintain airtight closure, preventing contamination of the mixing process and ensuring product quality over time.

Finally, proper storage is crucial for prolonging the life of stainless steel mixing vessels. When not in use, it is best to store them in a clean and dry environment, away from harsh chemicals or abrasive materials. Covering the vessel can also protect it from dust and environmental factors that may lead to tarnishing or damage. By adhering to these maintenance strategies, businesses can ensure that their stainless steel mixing vessels serve effectively for years to come.