The Agitator Mixing Tank plays a crucial role in various industries, from food production to chemical manufacturing. This tank combines different substances effectively, creating a homogeneous mixture. Its design features an agitator, which stirs the contents, ensuring uniformity and quality.

Inside the Agitator Mixing Tank, components are combined under specific conditions. The agitator's motion generates turbulence, promoting interaction among materials. However, the efficiency of mixing may vary based on factors like speed and viscosity. Sometimes, achieving the desired blend requires adjustments and careful observation.

While the Agitator Mixing Tank offers many benefits, it is not without its flaws. Poorly maintained tanks can lead to ineffective mixing or contamination. Understanding these challenges is essential for optimal operation. Overlooking such details may result in subpar products and wasted resources.

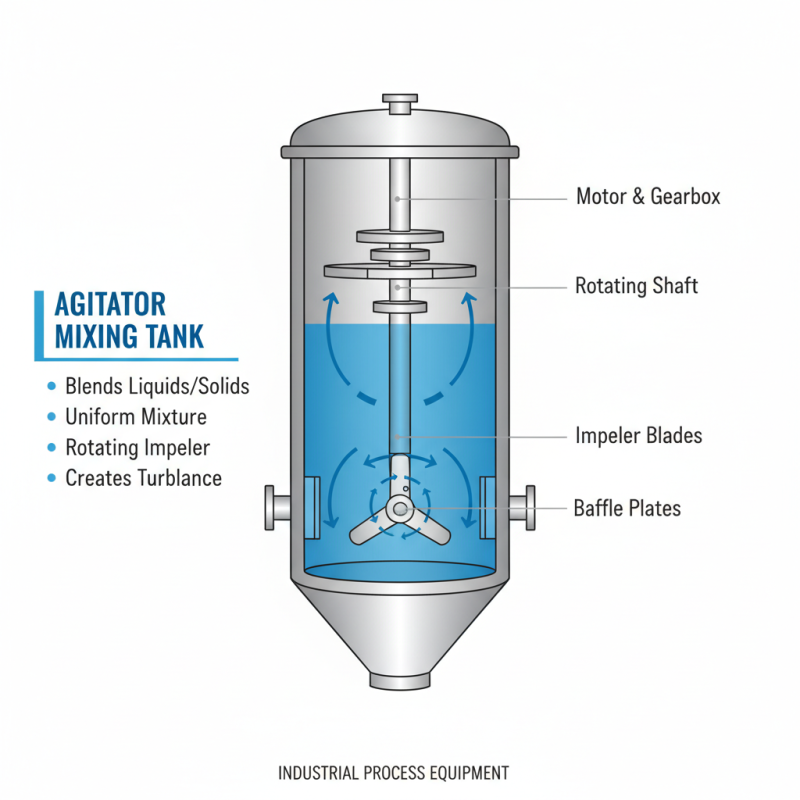

An agitator mixing tank is a crucial piece of equipment in various industries. It is designed to blend different liquids or solids into a uniform mixture. Typically, these tanks are cylindrical in shape. They have a rotating agitator or impeller inside. This component creates turbulence, helping to mix materials effectively.

The construction of an agitator tank varies. It can be made from stainless steel, glass, or plastic. The choice of material often depends on the substances involved. For instance, corrosive chemicals require specific materials to prevent damage. The size of the tank also matters. A larger tank can accommodate bigger batches, but it may be harder to clean.

Using an agitator mixing tank has its challenges. Sometimes, the materials might not mix evenly. This can be frustrating for operators. Adjusting the speed of the agitator can help, yet it may not always solve the problem. Proper maintenance is essential to ensure consistent performance. A well-maintained tank lasts longer and works more efficiently. However, overlooking small issues can lead to bigger headaches down the road.

An agitator mixing tank is essential in many industrial processes. Its primary role is to ensure uniform mixing of different substances. The effectiveness of these tanks largely depends on their key components. Understanding these components can enhance operational efficiency significantly.

One crucial part is the agitator itself. This device stirs and blends materials. Studies show that the type and design of the agitator can impact mixing efficiency by up to 40%. Another component to consider is the tank design. Tanks come in various shapes, such as cylindrical or conical. Each shape affects flow patterns differently. For instance, a conical tank may promote better solids suspension than a cylindrical counterpart.

The motor and drive system are also vital. They determine the speed and torque of the agitator. An inadequate motor can lead to poor mixing results. Such shortfalls can affect production output, leading to costly delays. Moreover, the choice of materials for constructing the tank must not be overlooked. Certain chemicals can corrode specific materials, creating safety hazards. A good approach is to review performance data from previous projects. This can help in making informed decisions about design and materials for the agitator mixing tank.

Agitator mixing tanks are essential in various industries, including food, pharmaceuticals, and chemicals. They utilize mechanical agitation to blend materials efficiently. The principle of operation relies on creating a vortex, which ensures uniform distribution of ingredients. When immersed in a liquid, the agitator creates turbulence and shear forces. This promotes faster mixing and reduces processing time.

According to industry reports, an efficient agitation system can enhance mixing quality by up to 30%. The size and speed of the agitator play crucial roles in the mixing process. Slow agitation may not achieve desired results, while excessive speed can cause foam or aeration issues. These challenges necessitate careful design and operation. Understanding the characteristics of the materials being mixed is equally important.

Sometimes, operators overlook specific parameters, leading to suboptimal performance. For instance, the wrong choice of impeller type can hinder mixing efficiency. Regular assessment of mixing effectiveness is vital. This can be done through visual checks or more sophisticated methods like particle size analysis. Investing in proper training for personnel can mitigate these issues and enhance the overall operation of agitator mixing tanks.

Agitator mixing tanks are essential in various industries. They rely on different types of agitators to blend materials efficiently. Some of the most common agitators include turbine mixers, paddle mixers, and helical mixers. Each type serves a unique purpose, depending on the material properties and the desired mixing outcome.

Turbine mixers are popular due to their high shear capabilities. They create a strong flow pattern that enhances the mixing of viscous liquids. Studies estimate that using turbine agitators can increase mixing efficiency by up to 40% compared to other types. On the other hand, paddle mixers are preferred for delicate materials, as they provide a gentler mixing action. They are effective for both solids and liquids, yet they may require longer processing times.

Helical mixers are gaining traction in industries that deal with powders. They can effectively mix dry ingredients, achieving a homogenous blend in shorter time frames. However, their design can sometimes lead to inefficient mixing in batches, especially with high-density materials. It's crucial for operators to regularly evaluate the performance of these agitators and make necessary adjustments. Without proper monitoring, inefficiencies can lead to inconsistent product quality.

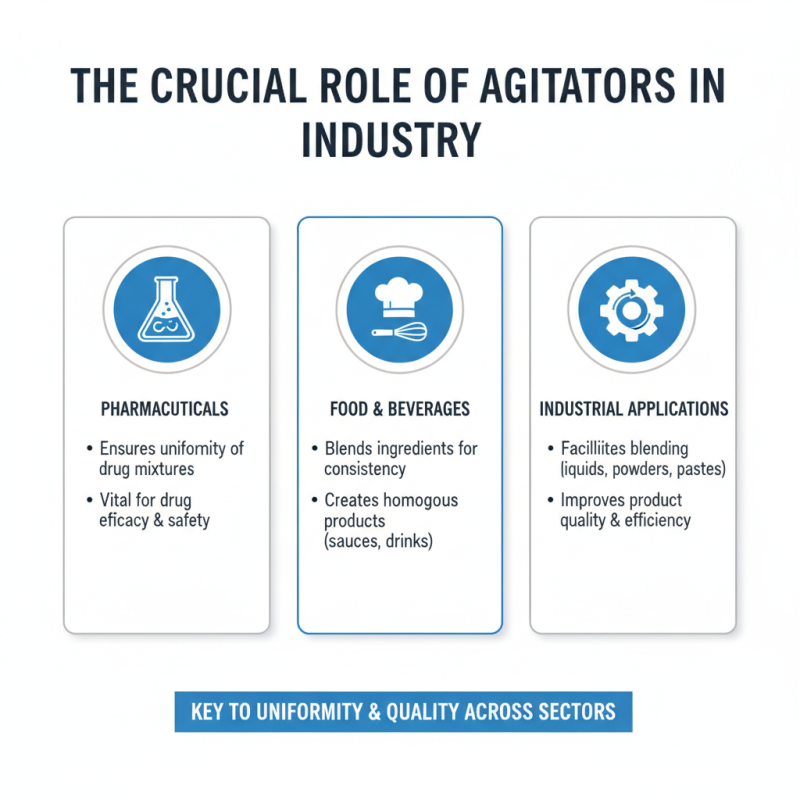

Agitator mixing tanks play a crucial role in various industries. They facilitate the blending of liquids, powders, and pastes. In pharmaceuticals, these tanks ensure the uniformity of mixtures. This consistency is vital for drug efficacy. Food and beverage industries also rely on agitators for mixing ingredients. They create homogenous products, from sauces to beverages.

In chemical processing, agitator mixing tanks aid in reactions. They maintain temperature and pressure, ensuring efficient chemical transformations. The versatility of these tanks allows for custom designs to meet specific needs. However, users must consider potential challenges. Improper mixing can lead to inconsistent products. Regular maintenance is key to avoid breakdowns.

**Tip:** Always monitor the mixing speed. Too fast may cause splashing, while too slow may not mix properly. Another tip: inspect seals and gaskets regularly. A small leak can cause significant issues. Additionally, training operators is essential. Familiarity with the tank's operation can prevent mistakes.