The Bag on Valve (BOV) filling machine is revolutionizing the packaging industry by providing a safe, efficient, and environmentally friendly alternative for aerosol products. According to a recent report by Smithers Pira, the global aerosol market is projected to reach over $92 billion by 2025, highlighting a growing demand for innovative packaging solutions. The BOV technique allows for consistent product dispensing while keeping the contents free from propellant contamination and external environment, making it an attractive option for manufacturers aiming to enhance product integrity and shelf life.

Expert in packaging technology, Dr. Jane Thompson, emphasizes the significance of this innovation, stating, "The Bag on Valve filling machine not only improves the reliability of product delivery but also aligns with the industry's shift towards sustainable practices." This technology utilizes a flexible bag contained within a can, delivering the product without the use of traditional propellants, thus reducing environmental impacts and increasing consumer preference for eco-friendly options. As the market continues to evolve, the BOV filling machine stands out as a pivotal solution for brands looking to meet consumer demands while supporting sustainability.

A Bag on Valve (BOV) filling machine is a specialized device designed to fill pouches or bags that are fitted with a valve, allowing for the dispensing of products in a controlled manner. This technology has gained traction in various industries, including food and beverage, cosmetics, and pharmaceuticals, thanks to its ability to maintain product integrity and extend shelf life. According to recent industry reports, the BOV market is expected to grow significantly, driven by the increasing demand for aerosol and non-aerosol packaging solutions.

The BOV filling machine operates by sealing a flexible bag inside a rigid container, which is pressurized with a propellant. This method not only minimizes product waste during dispensing but also ensures that the product maintains its quality without exposure to external contaminants. Recent studies indicate that BOV technology can improve the preservation of sensitive formulations, such as those containing natural ingredients, by preventing contact with air. Furthermore, the global market for BOV filling machines is projected to witness a compounded annual growth rate (CAGR) of around 5.4% over the next several years, highlighting the efficiency and effectiveness of this innovative packaging method.

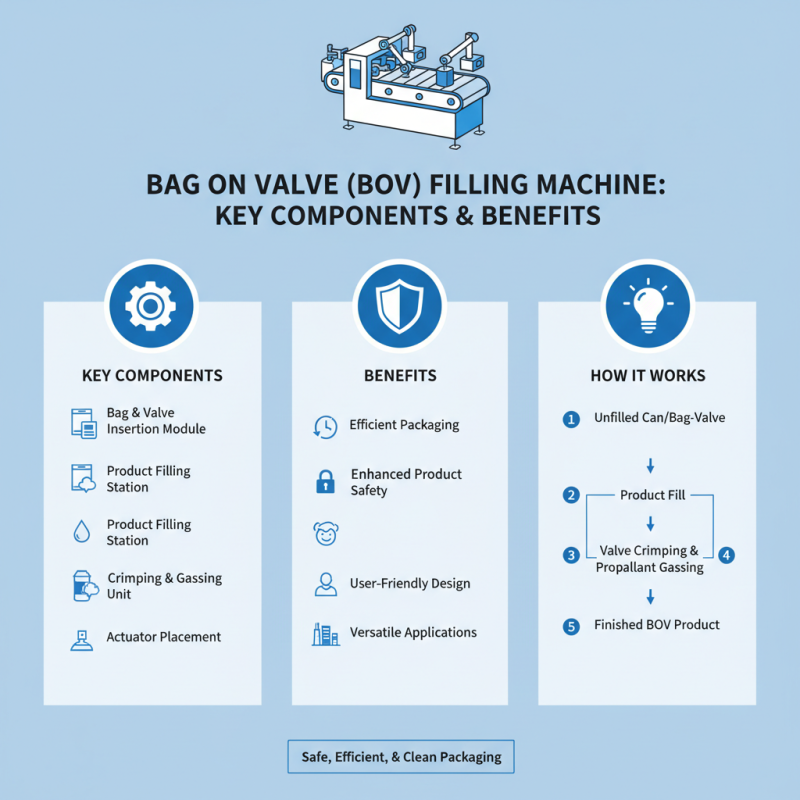

A Bag on Valve (BOV) filling machine is specifically designed for the packaging of products in an efficient, safe, and user-friendly manner. The key components of a BOV filling machine are crucial for its functionality and effectiveness in delivering high-quality packaging solutions. Understanding these components is vital for appreciating how this technology works and how it can be beneficial across various industries.

One of the primary components of a BOV filling machine is the product container, which houses the bag that holds the product. The bag is typically made from a flexible material that allows for efficient filling while minimizing contamination. The filling mechanism is another essential aspect, often utilizing a precision pump system to ensure accurate volume dispensing of the product into the bag. This mechanism allows for various viscosities and pressures, making it adaptable for a wide range of substances.

Additionally, the valve assembly is a significant part of the BOV system, ensuring that the product can be easily dispensed while preventing backflow and contamination. The valve is designed to allow for an effective seal, maintaining the integrity of the product inside the bag. Other components such as control panels and safety features further enhance the usability and reliability of the machine, allowing operators to efficiently monitor and adjust the filling process as needed. Overall, these components work together seamlessly to provide a reliable and efficient packaging solution.

The Bag on Valve (BOV) filling process is a sophisticated method widely used in packaging various products, particularly in the cosmetic and food industries. This technique involves filling a collapsible bag, which is housed within a can or aerosol container, with the desired product. The unique design allows for the product to be dispensed without coming into contact with the propellant, ensuring the purity and integrity of the contents. According to industry reports, the global Bag on Valve market is expected to reach approximately USD 1.5 billion by 2025, showcasing a compound annual growth rate (CAGR) of around 5.3% from 2020 to 2025, driven by increasing demand for eco-friendly packaging solutions.

The filling process itself begins by precisely placing the bag within the canister. A filling machine then injects the product into the bag under controlled pressure, ensuring optimal filling while minimizing product waste. Once filled, the valve is sealed tightly, ensuring that the contents remain uncontaminated and maintaining their quality over time. This method not only enhances the shelf life of the products but also provides consumers with a user-friendly experience. Recent advancements in filling technologies have led to greater efficiency and reduced operational costs, making BOV systems an attractive choice for manufacturers looking to modernize their packaging lines.

Bag on valve (BOV) filling machines have gained significant popularity in various industries due to their numerous advantages. These machines provide a unique packaging solution that separates the product from the propellant, ensuring better preservation of the product’s integrity. According to recent industry reports, the global demand for BOV filling machines is expected to grow at a CAGR of 4.5% from 2021 to 2028, driven by increased consumer preference for aerosol products that are eco-friendly and safe.

One major advantage of using bag on valve filling machines is the extended shelf life of the products they package. By isolating the product from the propellant, BOV systems mitigate the risk of contamination and oxidation. This is vital for industries such as cosmetics and food services, where preserving product quality is essential. Moreover, these machines enable the use of various types of propellants, including air and gases, making them versatile across applications. According to market research by the Packaging Industry Association, companies that implement BOV technology report a 30% increase in customer satisfaction due to improved product performance.

Tips for optimizing the use of bag on valve filling machines include regular maintenance checks to prevent mechanical failures and utilizing high-quality bags for filling. Proper calibration of the filling nozzle is also crucial to ensure accuracy and reduce waste. Additionally, training staff on the specific operational procedures can enhance efficiency, leading to faster production times and reduced downtime. By leveraging these strategies, companies can maximize the benefits of BOV technology and improve their bottom line.

Bag on Valve (BOV) technology has gained significant traction across various industries due to its innovative approach to packaging. This method offers a cleaner and more efficient way to dispense products. In particular, the BOV filling machine is widely utilized in the cosmetics, food and beverage, pharmaceutical, and household care sectors. According to a report by Market Research Future, the global Bag on Valve market is projected to reach approximately $1.2 billion by 2025, driven by the increasing demand for sustainable and environmentally friendly packaging solutions.

One of the primary applications of Bag on Valve technology is in the cosmetic industry, where it is used for products such as lotions, aerosols, and sprays. The design effectively separates the product from the propellant, ensuring that consumers receive a consistent and high-quality application without the risk of contamination. The food and beverage industry has also adopted BOV technology, particularly for products that require a high level of hygiene and shelf life, such as sauces and dressings. A study by Smithers Pira highlights that nearly 20% of packaging innovations in food applications now utilize this technology to enhance product integrity and consumer safety.

Moreover, BOV systems are prominent in pharmaceutical markets, particularly for inhalable medications and personal care products. The precise dosing and extended shelf life obtainable through this packaging method align well with the stringent compliance standards required in pharmaceutical applications. According to a recent report, the share of BOV in the pharmaceutical sector is expected to surpass 15% within the next few years, reflecting a growing trend towards advanced packaging technology that ensures safety and efficacy for consumers.

| Dimension | Description | Applications | Industries |

|---|---|---|---|

| Working Principle | A dual-chamber system where the product is kept separate from the propellant, ensuring purity and stability. | Aerosol products, food packaging, pharmaceuticals. | Food and Beverage, Personal Care, Healthcare. |

| Benefits | Extended shelf-life, reduced product contamination, optimal product dispensation. | Cosmetic sprays, anti-itch sprays, whipped cream dispensers. | Cosmetics, Pharmaceuticals, Automotive. |

| Types of Products | Lotions, creams, gases, foams. | Aerosolized medications, cleaning agents, hair sprays. | Household Products, Medical Products. |

| Filling Process | The product is filled into an inner bag, which is then placed in a container before the propellant is added. | Food items, personal care liquids, industrial lubricants. | Food Industry, Chemical Industry, Consumer Goods. |