In the realm of industrial mixing, the significance of an Agitator Mixing Tank cannot be overstated. These tanks serve as pivotal tools in numerous sectors, ranging from food and beverage to pharmaceuticals, providing optimal blending and ensuring uniformity in product quality. According to industry expert Dr. Jane Smith, a leading researcher in mixing technology, "The proper utilization of an Agitator Mixing Tank can dramatically enhance operational efficiency while reducing production time." This insight emphasizes the transformative potential of these tanks in various applications.

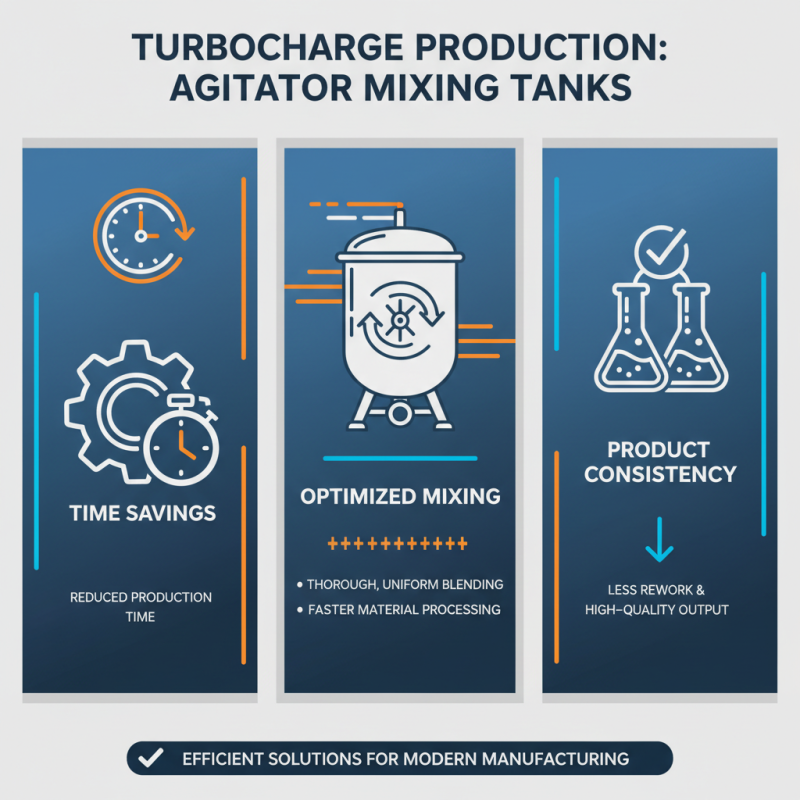

The benefits of using Agitator Mixing Tanks extend beyond mere mixing capabilities; they streamline processes, improve homogeneity, and increase production efficiency. Moreover, with technological advancements, modern agitator tanks are designed to cater to specific needs, accommodating a diverse range of materials and viscosities. Companies that prioritize the adoption of these innovative mixing solutions are not only enhancing their production capabilities but also gaining a competitive edge in the market. As we delve into the top 10 benefits of Agitator Mixing Tanks, it becomes clear why they are an essential component in the quest for efficient and effective mixing solutions.

Agitator mixing tanks are essential in various industries for their ability to provide enhanced homogeneity during the mixing process. One of the primary benefits of these tanks is their capacity to ensure that all components of a mixture are uniformly blended, which is crucial for achieving consistent product quality. This uniformity helps in reducing batch-to-batch variation, ensuring that each output meets the required standards without significant discrepancies.

Tips for achieving optimal mixing in agitator tanks include adjusting the agitation speed according to the viscosity of the materials being mixed. Higher viscosity often requires slower speeds to prevent damage to the product and ensure even blending. Additionally, using the correct impeller design can significantly enhance mixing efficiency; for instance, certain designs are better suited for specific applications, like dispersing solids or emulsifying liquids.

Maintaining proper tank design is also vital for enhanced homogeneity. Ensure that the tank has adequate shape and size based on the volume of materials processed. A well-designed tank minimizes dead zones, where materials can stagnate, leading to uneven mixtures. Regular maintenance and monitoring of the mixing process also contribute to the overall efficiency and effectiveness of the operation, further promoting homogeneity in the final product.

Agitation technology plays a crucial role in enhancing process efficiency within various industries, specifically through the use of agitator mixing tanks. These tanks facilitate thorough mixing of components, which is essential for achieving uniformity and consistency in products.

By promoting better interaction among ingredients, agitation minimizes the time and energy required for mixing, leading to increased productivity. The improved flow dynamics created by agitator mixing tanks ensure that even the most challenging materials achieve the desired homogeneity, thereby optimizing the entire production process.

Moreover, the implementation of advanced agitation techniques directly impacts the quality of the final product. With precise control of mixing parameters, such as speed and duration, manufacturers can tailor the process to meet specific requirements.

This adaptability not only enhances product quality but also reduces waste and improves yields. As industries seek to streamline operations and cut costs, investing in agitator mixing tanks with effective agitation technology emerges as a strategic choice for fostering innovation and driving efficiency.

In the fast-paced world of manufacturing, time is of the essence, and efficient mixing solutions can significantly reduce production time. Agitator mixing tanks are designed to optimize mixing processes, ensuring materials are blended thoroughly and uniformly in a shorter amount of time. This efficiency is not just about speed; it's also about achieving consistency in the final product, which minimizes the need for rework or adjustments later in the production cycle.

Moreover, agitator mixing tanks allow for better control of mixing parameters, such as speed and duration, which can be tailored to specific processes and materials. This adaptability enables manufacturers to streamline operations and respond quickly to market demands. The result is a smoother workflow, reduced downtimes, and ultimately, faster turnaround on production schedules. By investing in efficient mixing solutions, companies can enhance their productivity and maintain a competitive edge in their respective industries.

Agitator mixing tanks are indispensable tools across a variety of industries, significantly enhancing operational efficiency and product quality. In the chemical processing sector, agitator tanks facilitate the homogenous blending of materials, ensuring consistent product specifications. According to a report by Grand View Research, the global industrial mixing technology market is projected to reach $5.96 billion by 2027, highlighting the growing reliance on advanced mixing solutions like agitator tanks. Their ability to mix solids, liquids, and gases makes them a versatile choice in sectors ranging from pharmaceuticals to food and beverage production.

In the food processing industry, for example, agitator mixing tanks are crucial for creating uniform mixtures, whether in the production of sauces, creams, or dairy products. A recent study published in the Journal of Food Engineering notes that effective mixing can reduce processing time by up to 30%, which translates to significant cost savings and improved product shelf life. Furthermore, the pharmaceutical industry employs these tanks for precise mixing of active ingredients, which is essential for maintaining the efficacy and safety of medications. The versatility of agitator mixing tanks demonstrates their critical role in improving productivity and product quality across diverse sectors.

| Benefit | Description | Industry Applications | Efficiency Rating |

|---|---|---|---|

| Enhanced Mixing Performance | Ensures homogeneous blending of materials. | Food Industry, Chemical Production | 9/10 |

| Versatile Applications | Suitable for various phases of mixing such as solids, liquids, and pastes. | Pharmaceutical, Cosmetics | 8/10 |

| Reduced Processing Time | Faster mixing leads to shorter production cycles. | Paints & Coatings, Adhesives | 9/10 |

| Cost-Effective | Minimizes waste and optimizes the use of raw materials. | Automotive, Recycling | 7/10 |

| Consistent Quality | Maintains product quality through uniform mixing. | Beverage Industry, Dairy Processing | 10/10 |

| User-Friendly Design | Ease of use and maintenance with modern controls. | Construction, Waste Management | 8/10 |

| Energy Efficient | Designed to reduce energy consumption during operation. | Mining, Oil & Gas | 9/10 |

| Scalability | Flexible design allows for scaling up production. | Chemical Engineering, Biotech | 8/10 |

| Safety Features | Built-in safety measures to protect operators. | Pharmaceuticals, Food Processing | 10/10 |

| Improved Material Handling | Easier handling of viscous and challenging materials. | Plastic Manufacturing, Textile Industry | 7/10 |

The cost-effectiveness of utilizing

agitator mixing tanks

in operations is a critical consideration for industries seeking to optimize their processes.

According to a report by Grand View Research, the global mixing technology market is expected to reach

$6.20 billion by 2025, showcasing a growing demand for efficient mixing solutions like

agitator mixing tanks. These tanks offer reduced operational costs through lower energy consumption and minimized processing times,

allowing companies to allocate resources more effectively.

Furthermore, agitator mixing tanks enable bulk production, which significantly decreases per-unit costs. The inherent design of these tanks promotes faster mixing and thorough blending of materials,

resulting in shorter batch times. A study published in the Journal of Chemical Engineering highlights that businesses leveraging

high-efficiency mixing systems can increase production rates by up to

30%, translating into tangible savings.

Tips: To maximize cost benefits, invest in a quality agitator that matches your specific mixing needs,

as this can lead to more efficient energy use. Additionally, regular maintenance of your mixing equipment will ensure

prolonged lifespan and reliability, further enhancing your operational cost savings.

Keeping an eye on innovative mixing technologies can also provide opportunities for savings and efficiency in the long run.