In the dynamic landscape of manufacturing, the demand for efficient and reliable Aerosol Filling Machines continues to grow, driven by increasing consumer preferences for aerosolized products across various sectors including personal care, household cleaning, and industrial applications. According to a recent report by Market Research Future, the global aerosol filling machine market is projected to expand at a CAGR of 5.3% from 2021 to 2027, highlighting the critical role these machines play in meeting production needs. As businesses strive to enhance their operational efficiency, the selection of the right filling machine becomes paramount.

Industry expert David Thompson, a renowned consultant specializing in packaging technologies, emphasizes, “The choice of an aerosol filling machine not only impacts production speed but also ensures product integrity and quality. In an era where consumers are increasingly discerning, businesses cannot afford to overlook this essential equipment.” With advancements in technology and automation, modern aerosol filling machines have evolved to offer enhanced precision and flexibility, catering to the diverse requirements of various industries.

This article dives into the top 10 best aerosol filling machines available today, equipped to meet the unique needs of your business. By analyzing key features, advantages, and industry trends, we aim to guide you in making an informed investment that can boost your production capabilities while aligning with market demands.

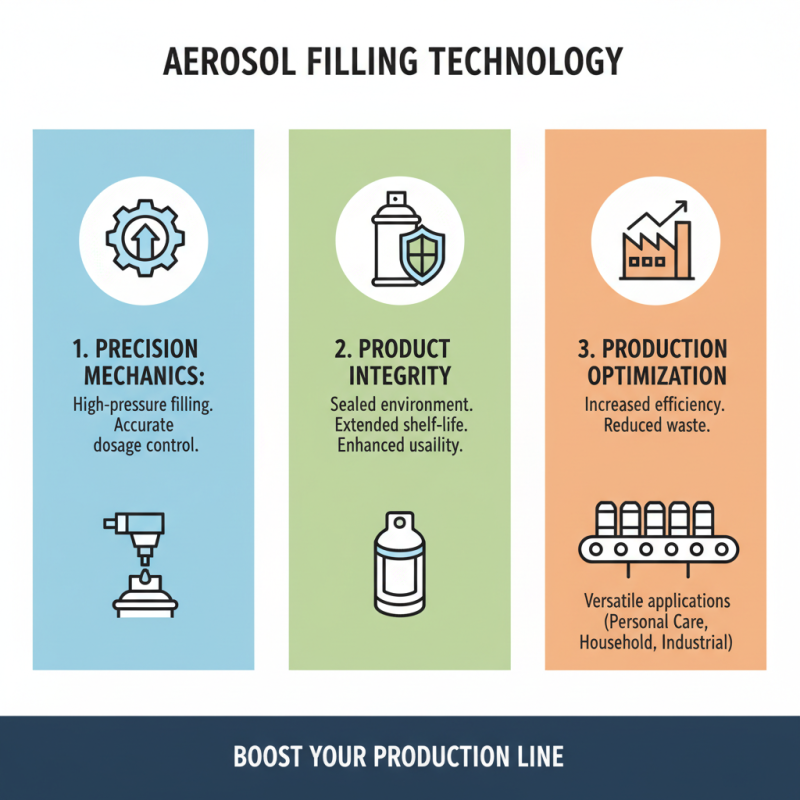

Aerosol filling machines play a critical role in various industries, ranging from personal care and household products to industrial applications. At the core of their functionality lies the ability to efficiently and precisely fill containers under high pressure while ensuring product integrity. This process not only enhances the shelf life of products but also improves their usability and consumer convenience. Therefore, understanding the mechanics of these machines is essential for any business looking to enhance its production line.

The significance of aerosol filling machines extends beyond mere efficiency; they are integral in maintaining safety standards and quality control throughout the filling process. By utilizing advanced technology, these machines minimize the risk of contamination and ensure accurate filling volumes, which is crucial for customer satisfaction. Moreover, as sustainability becomes an increasing priority, modern aerosol filling machines are designed with eco-friendly practices in mind, reducing waste and allowing for the use of recyclable materials. In essence, investing in the right aerosol filling machine not only augments a business's operational capabilities but also aligns with evolving market demands and environmental considerations.

When selecting the best aerosol filling machines for your business needs, it's crucial to focus on key features that enhance efficiency and precision. Look for machines with automated filling capabilities, which can significantly reduce labor costs and increase production speed. According to a report by Market Research Future, the aerosol packaging market is projected to grow at a CAGR of 4.76% between 2021 and 2027, highlighting the increasing demand for efficient filling solutions. A machine that incorporates advanced technology, such as programmable logic controllers (PLCs) and touch screen displays, can streamline operations and improve usability.

Another important consideration is the machine's adaptability to various product types. Many businesses require filling options for liquids, creams, gels, and other substances. Ensure the machine you choose offers adjustable filling volumes and nozzle types to cater to diverse product specifications. The ability to accommodate different container sizes is also critical, especially for companies aiming to diversify their product range.

**Tips:** Regularly maintain your aerosol filling machine to avoid costly breakdowns. Implementing a preventive maintenance schedule can prolong the lifespan of your equipment. Additionally, consider investing in training for your staff to ensure they are proficient in operating the machine, which can lead to increased productivity and reduced error rates.

This bar chart illustrates the filling speed of the top 10 aerosol filling machines, providing insight into their operational efficiency. Higher values indicate faster filling capabilities, which are crucial for optimizing production processes.

When selecting an aerosol filling machine, businesses must consider multiple factors to optimize efficiency and meet production needs. The market for aerosol filling machines is projected to grow significantly, with a CAGR of around 5.4% from 2021 to 2027, highlighting an increasing demand across various sectors such as personal care, household goods, and industrial applications. This growth is driven by the rising consumer preference for aerosol products due to their convenience and ease of use.

A comprehensive review of the top aerosol filling machines reveals essential features that can impact productivity and cost-effectiveness. Modern machines are equipped with advanced technologies such as automatic filling systems, which can enhance accuracy and reduce waste—a significant concern in any packaging process. Reports indicate that the efficiency of these systems can lead to an increase in output by up to 30% when compared to manual filling methods. Additionally, factors such as machine size, filling speed, and compatibility with various aerosol products are crucial in determining the ideal machine for specific business needs. By assessing these attributes, businesses can ensure they invest in equipment that not only meets their current requirements but also adapts to future growth and innovation in the aerosol market.

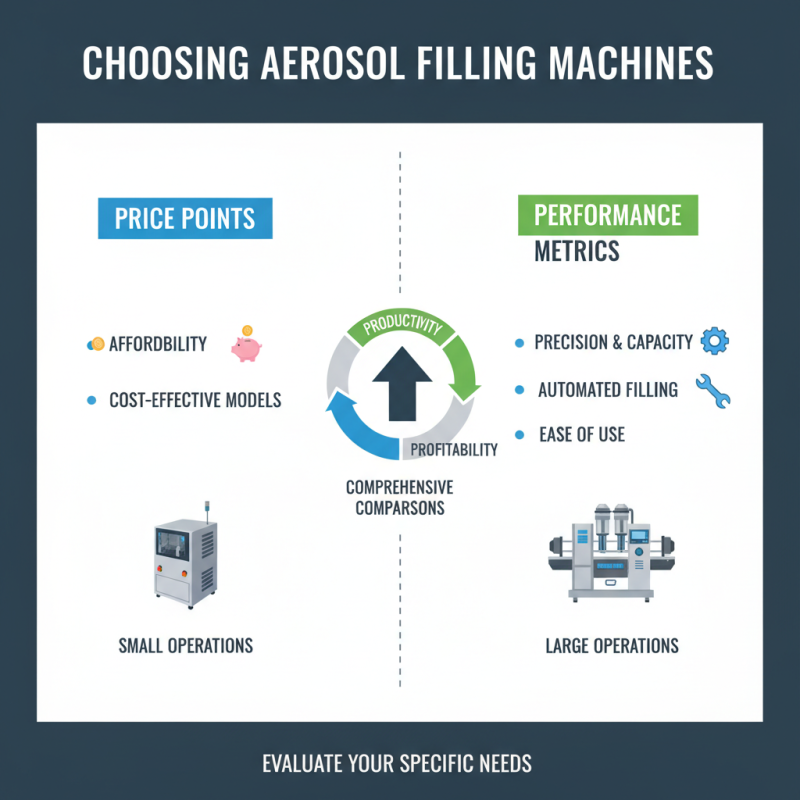

When considering the best aerosol filling machines for your business, it's essential to focus on both price points and performance metrics. The right machine can significantly impact your productivity and profitability, so conducting comprehensive comparisons is crucial. Some models may offer advanced features like automated filling, better precision, or higher capacities, while others may excel in affordability or ease of use. Evaluate your specific needs carefully; for example, if you run a small operation, a cost-effective, compact model may be the right choice, while larger operations might benefit from a robust, high-output machine.

When comparing models, look for machines that offer versatility in filling different sizes and types of aerosol containers. This feature can save costs in the long run as your business evolves. Additionally, consider maintenance requirements and the availability of parts, as these can affect operational downtime.

Tip: Always read customer reviews and case studies to gauge real-world performance. Actual user experiences can shed light on a machine's reliability and functionality, helping you make a more informed decision. Another tip is to request demonstrations or product trials whenever possible; this hands-on experience can clarify how well a machine will integrate with your production line.

Maintaining aerosol filling machines is crucial to ensure smooth operations and consistent product quality. Regular maintenance should include inspecting critical components such as valves, seals, and hoses for wear or damage. This proactive approach helps to prevent leaks and ensures optimal performance. It’s also essential to keep the machine clean, as residue buildup can cause malfunctions or contamination. Implementing a scheduled cleaning routine will enhance the longevity of the equipment and reduce the risk of downtime.

Best practices for operating aerosol filling machines involve training staff thoroughly on the proper use of the equipment. Employees should be instructed on how to handle the machines safely, including understanding the functions of various controls and emergency shutdown procedures. Additionally, keeping detailed logs of maintenance activities and production metrics is helpful for tracking performance trends over time, allowing for timely adjustments and improvements. Incorporating these maintenance and operational best practices will not only extend the life of the machines but also contribute to a more efficient and productive working environment.

| Machine Model | Filling Capacity (cans/min) | Type of Aerosol | Power Requirements | Maintenance Frequency | Best Practices |

|---|---|---|---|---|---|

| Model A | 30 | Foaming Agents | 220V, 50Hz | Monthly | Regularly check seals |

| Model B | 60 | Aerosol Paints | 380V, 3-phase | Weekly | Calibrate pressure settings |

| Model C | 45 | Cleaning Products | 240V, 1-phase | Bi-Weekly | Inspect for clogs |

| Model D | 90 | Automotive Sprays | 220V, 60Hz | Monthly | Perform routine cleaning |

| Model E | 75 | Personal Care Products | 220V, 50Hz | Weekly | Train operators regularly |

| Model F | 50 | Household Cleaner Sprays | 380V, 3-phase | Daily | Check for leaks |

| Model G | 25 | Lubricants | 220V, 50Hz | Monthly | Keep work area clean |

| Model H | 70 | Industrial Chemicals | 380V, 3-phase | Bi-Weekly | Verify safety switches |

| Model I | 35 | Fragrance Mists | 240V, 1-phase | Weekly | Monitor product levels |

| Model J | 55 | Aerosol Textiles | 220V, 60Hz | Monthly | Schedule downtime for checks |