Choosing the right Agitator Mixing Tank for your needs is a critical decision that can significantly impact the efficiency and effectiveness of your mixing processes. With a variety of options available on the market, selecting the ideal tank requires a careful assessment of several key factors, including your specific application, the properties of the materials being mixed, and the desired end results. Understanding these elements will guide you in making an informed choice that aligns with your operational requirements.

Agitator Mixing Tanks come in different sizes, designs, and configurations, each tailored to different industries and applications. Whether you're involved in pharmaceuticals, food production, or chemical manufacturing, the right tank can enhance mixing performance, improve product quality, and optimize production times. In this guide, we will explore crucial considerations that will aid you in selecting the best Agitator Mixing Tank to meet your unique needs, ensuring that your mixing processes are both efficient and effective.

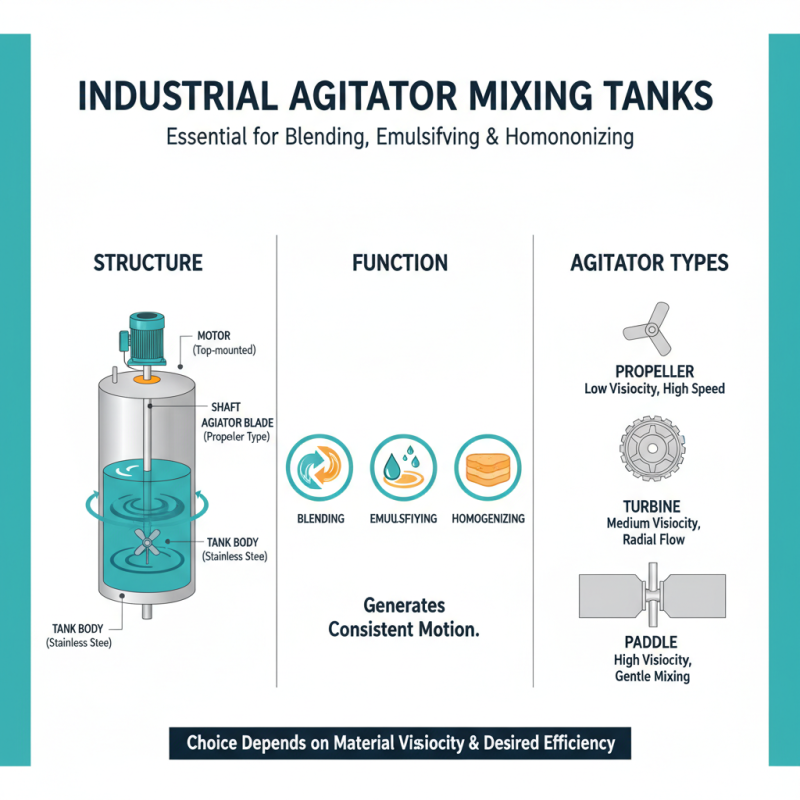

Agitator mixing tanks are essential tools in various industrial processes, designed to blend, emulsify, and homogenize different materials effectively. Understanding their structure and function is crucial for selecting the right tank for your specific needs. Typically, these tanks feature an agitator or mixer at the top, capable of generating consistent motion within the liquid medium. The choice of agitator design—whether it's a propeller, turbine, or paddle—depends on the viscosity of the materials being mixed and the desired mixing efficiency.

Considerations such as tank material, size, and configuration play a critical role in achieving optimal mixing results. For instance, stainless steel tanks are preferred in food and pharmaceutical industries due to their corrosion resistance and ease of cleaning. Additionally, the tank's capacity must align with the volume of the materials to be processed, ensuring that the mixing operation is both effective and economical. Moreover, understanding the principles of fluid dynamics can assist in optimizing the agitation process, allowing for better control over mixing times and product uniformity.

When selecting the right agitator mixing tank for your processes, it's essential to consider several key factors that can greatly affect your operational efficiency. First and foremost, assess the physical properties of the materials you'll be mixing. Factors such as viscosity, density, and temperature sensitivity will determine the type of mixer required. For instance, high-viscosity materials may necessitate a tank with a more powerful agitator design to ensure proper mixing.

Additionally, the tank's size and configuration are crucial elements to consider. Evaluate your production volume needs and the space available in your facility. A tank that is too small may lead to inefficiencies in mixing, while one that is unnecessarily large could result in wasted resources. Furthermore, consider the tank’s design features, such as baffles or the shape of the tank, as these can influence the mixing process significantly.

**Tips:** Always consult with mixing specialists to determine the best agitator type for your specific application. Testing pilot-scale models before full-scale production can also help avoid costly mistakes. Finally, don't forget to factor in maintenance needs; selecting a tank that is easy to clean and service can save time and labor in the long run.

| Factor | Description | Considerations |

|---|---|---|

| Tank Material | The material of the tank should withstand the properties of the liquid being mixed. | Corrosion resistance, temperature tolerance, compatibility with chemicals. |

| Agitation Type | Different applications may require specific agitation methods (e.g., radial, axial). | Mixing efficiency, shear sensitivity of the liquid, desired flow pattern. |

| Capacity | Tank capacity should align with production needs. | Expected volume, available space, growth projections. |

| Agitator Speed | The speed at which the agitator operates affects mixing quality. | Optimal speed for the product, variable speed options, energy consumption. |

| Heating/Cooling Options | Some processes may need temperature control during mixing. | Requirements for temperature range, heating/cooling efficiency, insulation properties. |

| Safety Features | Identification of potential hazards during operation. | Emergency shut-off, monitoring systems, explosion-proof designs. |

| Regulatory Compliance | Compliance with industry standards and regulations. | FDA, GMP, and environmental regulations. |

When selecting the right agitator mixing tank, understanding the various types of agitators and their applications is crucial. There are generally three primary categories of agitators:

axial flow, radial flow, and mixed flow.

Axial flow agitators are designed to minimize mixing dead zones, making them ideal for applications requiring high fluid circulation, such as in the chemical and pharmaceutical industries.

According to industry reports, these agitators can reduce energy consumption by up to 25% in large-scale mixing operations.

Radial flow agitators, on the other hand, are most effective for promoting suspension in heavy and viscous fluids, often found in mining and waste treatment applications.

Their ability to create shear forces allows for improved particle dispersion and better process efficiency.

Data from market analyses indicate a growing demand for radial flow systems, particularly within the environmental sector, projected to increase by 30% between 2023 and 2025 as more facilities seek to optimize their operational capabilities.

Mixed flow agitators provide a balance between axial and radial flow characteristics, making them suitable for applications that require both mass transfer and shear.

They are frequently utilized in the food and beverage industries, where maintaining product quality while ensuring thorough mixing is vital.

Reports highlight that adopting mixed flow designs can lead to a significant improvement in processing times and product consistency, enhancing overall production efficiency by as much as 20%.

Understanding these types and their specific applications allows businesses to make informed choices that cater to their unique mixing needs.

When selecting an agitator mixing tank, one of the most crucial factors to consider is material compatibility. The type of materials being mixed can significantly influence not only the efficiency of the mixing process but also the longevity and maintenance of the tank itself. According to industry reports, approximately 30% of mixing issues stem from inappropriate material choices, leading to premature wear and chemical reactions that can compromise both the product and equipment integrity. It's imperative to thoroughly assess the chemical properties of the substances involved, such as viscosity, density, and corrosiveness, and choose a tank material that can withstand these conditions.

Tips: Always consult material compatibility charts and perform compatibility tests when possible. For instance, stainless steel is often the preferred material for non-corrosive substances, while high-density polyethylene (HDPE) can be suitable for certain chemical processes. Additionally, consider the tank's design and mixing mechanism, as these can affect the tank's performance based on the mixed materials’ properties.

Another critical aspect to evaluate is the temperature and pressure conditions during the mixing process. Certain materials may degrade or change state under specific temperature conditions, which could potentially lead to safety hazards or product inconsistencies. Recent studies show that maintaining optimal temperature ranges can enhance mixing efficiency by up to 20%, underscoring the importance of selecting a tank that can accommodate these parameters while ensuring material compatibility.

Tips: Always factor in the operational environment, including temperature variations and pressure fluctuations, when choosing your mixing tank material. Investing time in this assessment can save costs and downtime in the long run.

When selecting the right agitator mixing tank, determining the size and capacity requirements is paramount for efficient mixing. The process begins with an analysis of the material properties, including viscosity and density, which directly influence the mixing efficiency. According to industry reports, using a tank that is too small can lead to inadequate mixing and increased processing times, while an oversized tank may result in wasted resources and energy. The optimal tank size should accommodate the volume necessary for your specific application, typically calculated based on the batch size and frequency of production.

Furthermore, tank capacity is crucial in maximizing operational efficiency. A recent study by market analysts highlights that properly sized mixing tanks can increase productivity by up to 30%, primarily by minimizing downtime between batches. To determine the required capacity, businesses should consider not only the current production demands but also anticipated future growth. Direct industry data suggests that companies should anticipate a 10-20% increase in capacity needs over the next five years, ensuring that their mixing solutions remain scalable and adaptable. Assessing both current and projected needs will ultimately guide companies in investing in the right agitator mixing tank, aligning with their operational goals while fostering efficiency.