When it comes to selecting a Stainless Steel Mixing Vessel for your specific needs, the decision can be both exciting and challenging. This essential equipment plays a critical role in various industries, including food processing, pharmaceuticals, and chemical manufacturing. As the demand for high-quality mixing solutions continues to rise, understanding the key features and factors that influence the selection of a stainless steel mixing vessel becomes paramount.

In this guide, we will explore the fundamental aspects to consider when choosing the right stainless steel mixing vessel. From tank size and shape to the types of mixing mechanisms, each element contributes to the overall efficiency and effectiveness of your mixing processes. Additionally, we will discuss the importance of material quality and design specifications that ensure durability and hygienic standards. With the right knowledge, you can make informed decisions that align with your operational needs and enhance productivity in your facility.

When selecting the right stainless steel mixing vessel for your needs, there are several key factors to consider to ensure optimal performance and functionality. Firstly, the size and capacity of the vessel should align with the volume of material you plan to mix. Assessing the scale of your operations will help you determine whether you need a small laboratory-scale vessel or a larger industrial unit.

Additionally, consider the mixing process itself. Different materials and applications may require varying degrees of agitation and mixing efficiency, which can be influenced by the vessel's design and shape.

Another crucial factor is the type of stainless steel used in the construction of the vessel. The grade of stainless steel can affect the vessel's durability, corrosion resistance, and suitability for specific applications. For instance, higher grades offer better resistance to chemicals and high temperatures, which is essential in industries like food processing or pharmaceuticals. Furthermore, features such as insulation, heating or cooling capabilities, and ease of cleaning should also be evaluated, as they can significantly impact operational efficiency and maintenance costs.

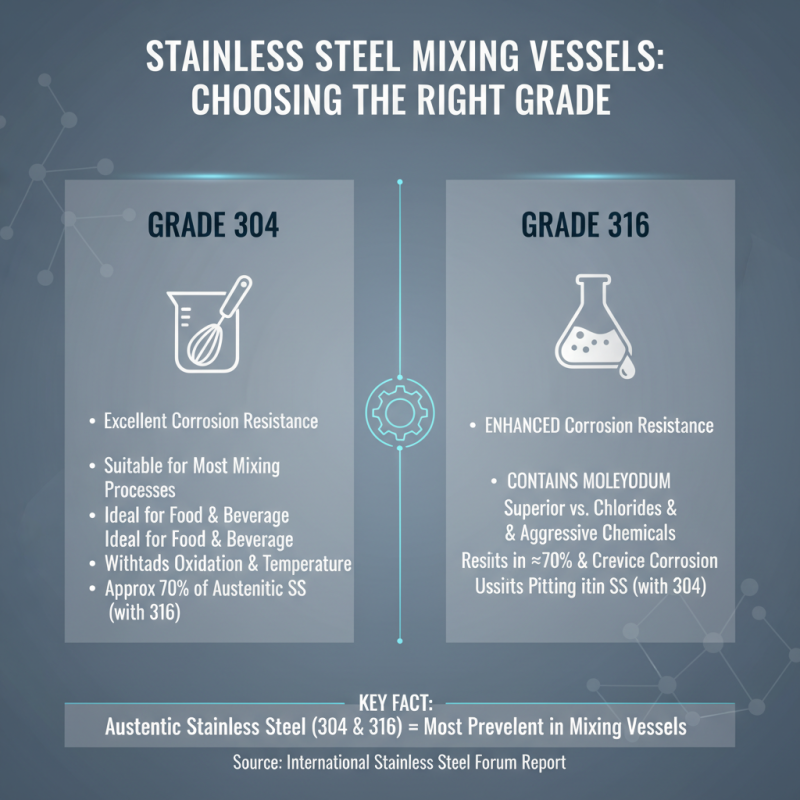

When selecting the appropriate stainless steel mixing vessel, it is crucial to understand the different grades of stainless steel and their inherent properties. The most commonly used grades in mixing applications are 304 and 316 stainless steel. Grade 304 offers excellent corrosion resistance and is suitable for most mixing processes, especially in food and beverage industries, due to its ability to withstand oxidation and maintain structural integrity at varying temperatures. However, for applications that involve exposure to chlorides or more aggressive chemicals, grade 316, which contains molybdenum, provides enhanced resistance against pitting and crevice corrosion. According to a report by the International Stainless Steel Forum, approximately 70% of the stainless steel produced globally is of the austenitic type, with 304 and 316 being the most prevalent grades used in mixing vessels.

Another significant factor to consider is the vessel's surface finish. A polished surface can reduce the risk of contamination and facilitate easier cleaning, which is vital in industries requiring stringent sanitation standards. The surface roughness can impact the vessel's performance, contributing to the overall durability and longevity of the equipment. A study published in the Journal of Materials Science indicated that vessels with a higher surface finish showed a considerable reduction in bacterial adhesion, an essential consideration for pharmaceutical and food processing applications. Therefore, when choosing a mixing vessel, it is imperative to evaluate both the stainless steel grade and the surface finish to ensure optimal performance for your specific operational needs.

When selecting a stainless steel mixing vessel, understanding your volume requirements is crucial. Start by assessing the total amount of material you need to mix. Consider not only the required final volume but also the necessary headspace to accommodate mixing without overflow. Typically, a good rule of thumb is to fill the vessel to around 70-80% of its capacity to allow for proper mixing and avoid spillage.

Tips: To calculate the optimal size for your mixing vessel, account for both the density of the materials and any pre-mixing conditions. For instance, if you work with thick pastes or powders, they may occupy more space and require a larger vessel than liquids.

Moreover, think about the scalability of your operations. If you plan to increase production in the future, it may be wise to opt for a larger vessel than you currently need. This approach not only saves you from having to invest in new equipment shortly after your initial purchase but also enables you to meet rising demand efficiently. Always remember that an appropriate vessel size can significantly impact mixing efficiency, consistency, and overall project success.

| Application | Volume (Liters) | Recommended Vessel Size | Material Thickness (mm) |

|---|---|---|---|

| Food Processing | 200 | 250L | 2.0 |

| Chemical Mixing | 500 | 600L | 3.0 |

| Pharmaceuticals | 100 | 150L | 2.5 |

| Brewery | 300 | 350L | 3.5 |

| Cosmetics | 50 | 75L | 1.5 |

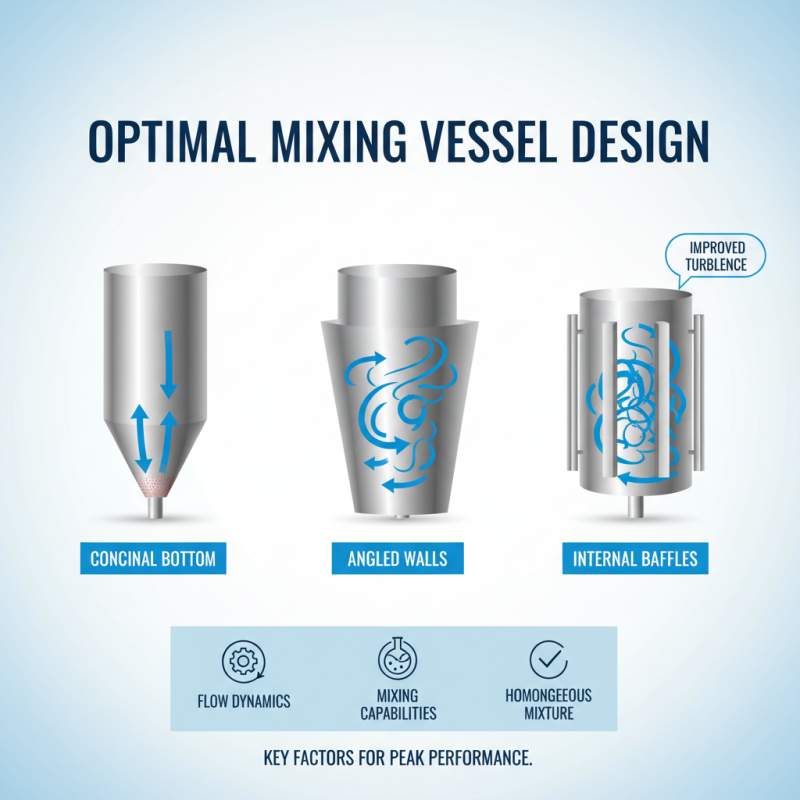

When selecting a stainless steel mixing vessel, the design of the vessel plays a crucial role in achieving optimal mixing efficiency and performance. Factors such as the vessel shape, size, and internal features directly impact the flow dynamics and mixing capabilities. For instance, a conical bottom design may enhance drainage and minimize dead zones, while an angled vessel wall can improve turbulence, allowing for a more homogeneous mixture.

Tips: Consider the specific properties of the materials you will be mixing. For viscous materials, a vessel with an agitator specifically designed to handle such consistencies can significantly enhance mixing performance. Similarly, the inclusion of baffles can enhance the mixing process by promoting wave motion and reducing vortex formation.

Another important aspect of vessel design is the choice of mixing equipment. The type of agitator used must be compatible with the vessel's design and the materials being processed. For example, a high-shear mixer is ideal for dispersing solids into liquids, while a paddle mixer might be more appropriate for blending bulk solids. Always evaluate your mixing requirements carefully to ensure the vessel is equipped with the right features to achieve your desired outcomes.

When selecting a stainless steel mixing vessel, balancing cost and quality can significantly impact the efficiency and longevity of your operations. According to a report by the International Stainless Steel Forum, the price of stainless steel has fluctuated between $1,700 to $3,000 per ton over the past five years, influencing production costs for mixing vessels. While it might be tempting to opt for cheaper alternatives to save upfront costs, inferior quality materials can lead to increased maintenance expenses and shorter lifespans. In fact, a study published in the Journal of Manufacturing Science and Engineering found that investing in higher-quality stainless steel mixing vessels could reduce maintenance costs by up to 30% in a five-year period.

Moreover, the specific requirements of your process must align with your budget considerations. Factors such as the vessel's capacity, the nature of materials being mixed, and compliance with industry standards all play crucial roles in determining overall cost. The American Society for Testing and Materials emphasizes that materials capable of withstanding specific temperatures and pressures not only enhance operational safety but also contribute to longer equipment life. Investing in quality vessels tailored to your operational demands can ultimately yield better returns, as industry analysis indicates that companies often save significantly on operational costs over time when they prioritize durability and functionality in their equipment purchases.

This chart illustrates the cost comparison of stainless steel mixing vessels across three quality levels: Low Cost, Mid Range, and High Quality. As indicated, the average cost significantly increases with higher quality, emphasizing the importance of evaluating both budget and quality when making a purchasing decision.