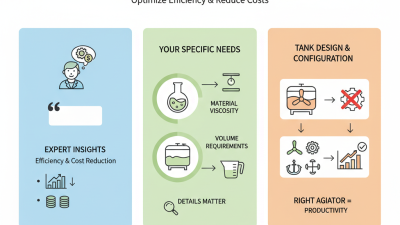

Choosing the right Agitator Mixer Tank can be a challenging task. With various options available, each with specific features, it’s easy to feel overwhelmed. The choice depends on your unique needs. Understanding the purpose of the tank is essential. Different industries demand distinct mixing solutions.

When selecting an agitator mixer tank, consider factors like size, material, and mixing speed. The tank's size must match your production requirements. Each industry, whether food, pharmaceuticals, or chemicals, has unique specifications. Sometimes, users forget this and choose inadequately sized tanks.

Evaluate the agitator design as well. It plays a crucial role in achieving the desired mixing quality. Certain designs may perform better than others for specific applications. Reflecting on past choices might help identify what’s missing now. Your needs might have changed since the last purchase. A thoughtful approach can lead to better results with an agitator mixer tank.

When selecting an agitator mixer tank, it's essential to understand the different types available. There are several categories, each catering to specific applications. For instance, a paddle mixer is ideal for gentle mixing and is often used in food processing. It helps in blending materials without causing damage. However, it might not achieve the uniformity needed in some industrial applications.

On the other hand, a high-shear mixer is excellent for thick liquids or pastes. This type uses a rotor-stator system to create intense shear forces, making it perfect for emulsifying and homogenizing products. However, the complexity of operation can sometimes lead to maintenance challenges. It's necessary to consider whether your workforce has the skills to manage such equipment.

Another option is the turbine mixer. This is effective for larger batches and can handle a variety of viscosities. However, it may struggle with very dense materials. Understanding the limitations of each type is crucial. Careful consideration will help ensure that the chosen mixer tank aligns well with production goals.

When selecting an agitator mixer tank, several key factors demand attention. The tank's size matters significantly. A tank that is too small might not accommodate your mixing needs. Conversely, a larger tank may require excessive space and resources. It’s essential to assess the volume of material you plan to mix regularly. Understand your operation better by analyzing what's typical for your processes.

The design and shape of the tank come next. Different shapes provide varying mixing efficiencies. A taller, narrower tank can create a distinct flow pattern compared to a wider, shallower one. Think about the type of mixing required. Are you blending liquids, solids, or both? Mixing speed and the type of agitator are also crucial for achieving the desired consistency. Testing a few variations might highlight unexpected challenges.

Finally, material compatibility is vital. Not all tanks can handle every substance without deterioration. Corrosive materials may require special coatings or materials. Reflecting on these elements will guide you. Consider your specific requirements. Each detail may seem minor but has the potential to impact your operation greatly.

Choosing the right agitator mixer tank is crucial for your specific process. Understanding your mixing requirements is the first step. Different processes require different mixing intensities and types. For example, a report from the Mixing Technologies Association (MTA) highlights that over 40% of mixing issues stem from improper agitator selection. This statistic emphasizes the need for precise measurement of viscosity and density in your materials.

Tips: Assess your material properties carefully. Key variables include flow characteristics, temperature, and reaction times. These factors can significantly influence the choice of agitator type. It’s also essential to consider your tank's volume and shape, as these will affect mixing efficiency. Ensure you test and evaluate various configurations.

Some processes need gentle mixing, while others require high shear. The type of mixer strongly influences the outcome. A lack of understanding in this area could lead to inconsistent product quality. Rethink your choices if you experience issues with mixing uniformity or stability. It’s worth noting that even small changes in the mixer design can lead to substantial improvements in performance.

When choosing an agitator mixer tank, the materials and construction are crucial factors. Stainless steel is popular due to its durability and resistance to corrosion. It’s ideal for mixing chemicals or liquids that may cause wear. However, it can be costly and not always necessary. For less demanding applications, carbon steel may suffice. It’s cheaper but requires proper coatings to avoid rust.

Consider the tank’s design as well. A well-constructed tank ensures efficient mixing and stability. Look for features like reinforced seams for additional strength. The thickness of the tank walls also matters. Thinner walls may lead to leaks or fail under pressure. If you're mixing substances that generate heat, you might need insulated tanks. This adds complexity and cost, so think through your requirements carefully.

It's vital to reflect on your specific needs. Often, we overlook the long-term implications of our choices. What seems perfect now may not work later. Switching materials or designs post-purchase can be frustrating. Assess your processes thoroughly before making a decision. Choose wisely to avoid potential pitfalls down the line.

When working with agitator mixers, maintenance is key. Regular checks can prevent unexpected failures. Monitor the seals and bearings closely. A minor leak can lead to bigger issues if ignored. Listen for unusual noises during operation. They may indicate wear or misalignment. These are early warnings that shouldn't be overlooked.

Operational considerations are equally important. Ensure your tank is the right size for your needs. An oversized tank may waste energy. It's crucial to match the mixer speed to the viscosity of the materials. A too fast speed can lead to foam formation, leading to inefficiency. It's a delicate balance. Regular calibration of your equipment is advised. Miscommunication between operators can lead to mistakes.

Don’t forget to train your staff. Even experienced workers can overlook basics. Encourage them to share observations on performance. A small change can make a significant difference. Create a culture of continuous improvement. After all, the goal is to maximize efficiency and lifespan.