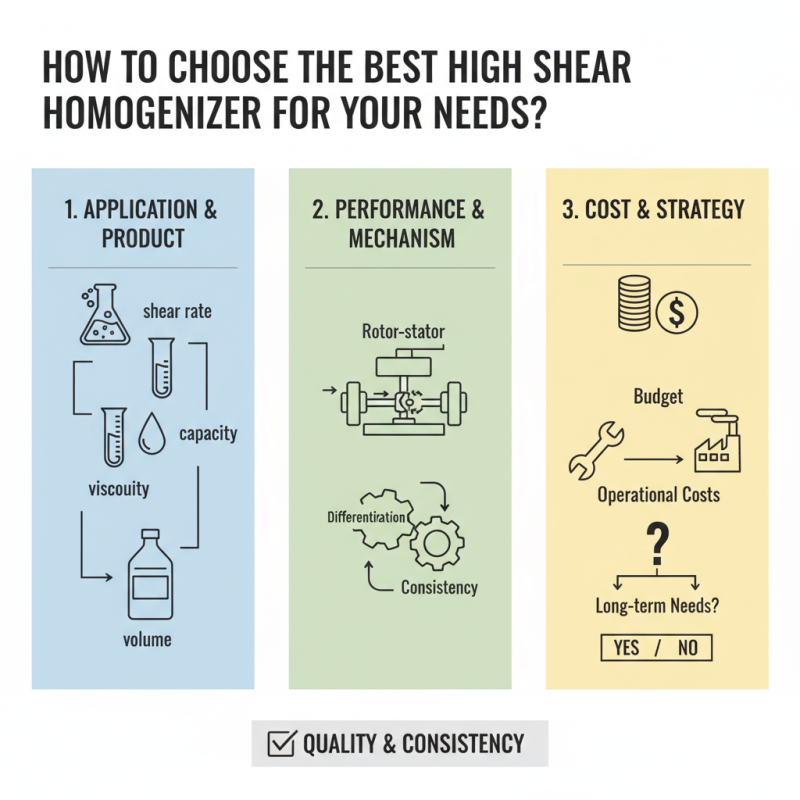

Choosing the right High Shear Homogenizer is crucial for your specific needs. These devices are essential in industries like food, pharmaceuticals, and cosmetics. The right homogenizer ensures quality and consistency in products.

When selecting a High Shear Homogenizer, consider the application. Different processes require varying shear rates and capacities. Understand your product's viscosity and volume. Not all homogenizers perform the same way.

Additionally, reflect on the budget. Some models may seem ideal but come at a high cost. Think about maintenance and operational costs too. It’s important to ask yourself if the equipment will meet your long-term needs. This decision is not just technical; it’s strategic.

High shear homogenizers play a crucial role in various industries, including food, pharmaceuticals, and cosmetics. These machines provide efficient mixing and particle size reduction. A report from the International Journal of Pharmaceutical Sciences noted that high shear homogenizers can reduce particle sizes to less than 10 microns. This is vital for ensuring product consistency and stability.

In food applications, high shear homogenizers help achieve emulsions and dispersions that are smoother and more uniform. A study in the Journal of Food Engineering highlighted that proper homogenization can improve the mouthfeel and taste of products. However, achieving the right shear rate requires careful consideration. Not every product demands the same intensity. Over-processing can lead to degradation of sensitive ingredients.

The selection of a high shear homogenizer depends on your specific needs. Understanding the viscosity and temperature sensitivity of materials is essential. For example, some formulations may require lower shear rates, while others need aggressive mixing. It's essential to balance energy input and output. Choosing the wrong machine can compromise product quality and lead to inefficient production. Conducting thorough testing is crucial to avoid mistakes.

This bar chart illustrates the efficiency of various high shear homogenizer models in reducing viscosity. The data represents the percentage of viscosity reduction achieved by each model, which is crucial for selecting the right homogenizer based on specific application needs.

Choosing the right high shear homogenizer involves several key factors. The application is critical. Are you working with emulsions, suspensions, or something else? Each application has unique requirements. Your choices will deeply affect product quality.

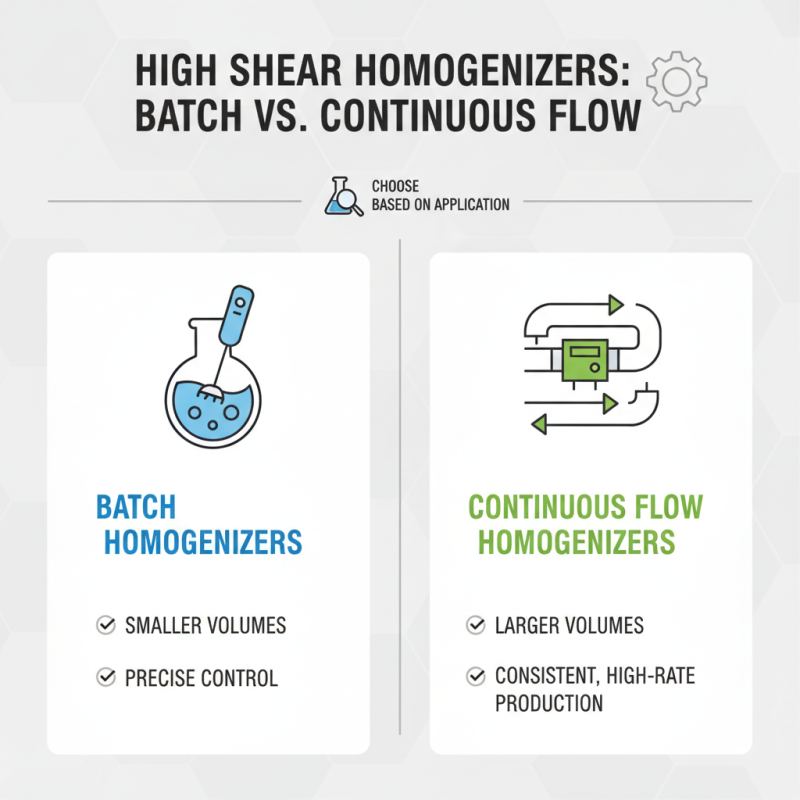

Consider the size of your batches. A smaller batch may need a different model than a large one. Easy-to-clean features can save time and improve efficiency. Think about where you will use the homogenizer. Will it be in a lab or a manufacturing setting? This can influence your decision.

Pay attention to the materials used in the homogenizer. Corrosion-resistant materials are vital for certain products. Evaluate the energy consumption of different models. A more efficient unit could save money. Lastly, don’t forget to reflect on customer support. If something goes wrong, how easy is it to get help? Don't skip this step, as it can impact your experience.

When comparing different types of high shear homogenizers, it’s crucial to consider your specific application. Batch homogenizers work well for smaller volumes. They often offer precise control over the mixing process. Continuous flow homogenizers are better for larger volumes. They provide consistent results and are more efficient for high production rates.

It’s also important to think about the shear rate required for your materials. Some products need gentle mixing, while others demand intense shear forces. The design of the homogenizer impacts performance. Rotor-stator systems are common. They provide high shear rates but may not be suitable for heat-sensitive materials.

Consider maintenance needs too. Regular cleaning and part replacements may be burdensome. Finally, always reflect on the initial cost versus long-term investment. Cheaper options might save money upfront but lead to higher operational costs in the future. Scrutinizing these factors helps you make an informed choice. The most effective homogenizer balances performance, cost, and usability for your unique requirements.

When selecting a high shear homogenizer, performance specifications are crucial. Key factors include shear rate, flow rate, and energy consumption. The shear rate should match your process requirements. A higher shear rate often leads to finer emulsions. According to recent industry reports, optimal shear rates can range from 3,000 to 20,000/sec for various applications.

Flow rate is another critical metric. Your production volume will dictate minimum and maximum flow rates. For instance, small-scale operations might require a flow rate as low as 1 L/h, while larger processes can exceed 500 L/h. A mismatch here can lead to inefficiencies and inadequate processing.

Consider energy consumption as well. Not all high shear homogenizers are designed for efficiency. Some may consume excessive power, leading to higher operational costs. Reports suggest that modern homogenizers can achieve desired results with significantly lower energy consumption, impacting both cost and sustainability. Be mindful of these factors, as overlooking them could hinder your processing quality. Assessing these specifications will help you make a more informed decision.

When considering a high shear homogenizer, budgeting plays a crucial role. Prices can vary dramatically based on features, capacity, and brand. A basic model may start around $1,000, while advanced machines can exceed $10,000. Understanding your requirements beforehand can help prevent overspending.

According to a recent industry report, around 60% of users believe they overpaid for their homogenizers. Many failed to consider ongoing costs such as maintenance, parts replacement, and operational efficiency. These factors can add up quickly and impact your overall budget.

**Tip:** Always calculate the total cost of ownership. It’s not just about the initial purchase price.

Consider the scale of your operations. If you typically process small batches, a larger unit could be excess and wasteful. Conversely, if your needs grow, an undersized unit can lead to inefficiencies. Balancing upfront costs with the potential for future growth is essential.

**Tip:** Think about your long-term needs, not just immediate ones.

Many buyers overlook the importance of energy consumption. This can become a significant factor over time. A more energy-efficient model may have a higher upfront cost but can save money in the long run. Be diligent and plan accordingly.

| Homogenizer Type | Power (HP) | Price Range ($) | Max RPM | Application Suitability |

|---|---|---|---|---|

| Laboratory Homogenizer | 0.5 - 2 | 1,000 - 3,000 | 5,000 - 30,000 | Small batches, research applications |

| Pilot-Scale Homogenizer | 2 - 5 | 5,000 - 15,000 | 10,000 - 40,000 | Medium-scale production, formulation |

| Industrial Homogenizer | 5 - 50 | 15,000 - 100,000 | 20,000 - 60,000 | Large-scale production, food and pharma |