As the demand for aerosol products continues to rise, selecting the right Aerosol Filling Machinery has never been more crucial. According to a market research report by Grand View Research, the global aerosol market is expected to reach $182.5 billion by 2027. This growth underscores the importance of efficient filling technology. Businesses must confront several challenges when choosing machinery, including varying product viscosities and container types.

When considering Aerosol Filling Machinery, the efficiency of your production line can either enhance or hinder success. A poorly chosen machine may lead to increased downtime and waste. For instance, even a 1% increase in production efficiency can result in significant cost savings over time. It is essential to ask the right questions and conduct thorough research. Understanding regulatory compliance and machine maintenance will aid in making a more informed decision.

Investing in quality Aerosol Filling Machinery does not come without its own set of challenges. For example, the initial cost may be daunting. However, the long-term benefits often outweigh the upfront investment. Carefully evaluating your business needs will guide you toward the best machinery for your specific applications. Failure to do so could leave you with inefficiencies that impact your bottom line.

When selecting aerosol filling machinery, understanding the various types available is crucial. There are several machines designed for different applications. For instance, gravity fillers work well for thicker products, while pressure fillers are ideal for lighter liquids. Each type has its pros and cons. Research shows that about 60% of businesses struggle by not assessing their specific needs beforehand.

It's essential to consider automated versus manual systems. Automated machines increase efficiency and reduce labor costs. According to industry reports, around 75% of companies that implemented automation saw a 20% rise in production. However, manual machines may be better for smaller operations. They require less capital investment but could lead to inconsistent filling.

When evaluating the options, think about your production capacity. High-speed lines may seem attractive. But not every business needs that level of output. A mismatch here can result in wasted resources and lower ROI. Also, maintenance costs can be overlooked. Some machines are costly to maintain over time, affecting overall profitability. Evaluate these factors carefully to make an informed decision.

When selecting aerosol filling machinery, understanding your production capacity needs is crucial. An industry report indicates that businesses should assess their expected output levels, as efficiency can vary significantly across machinery types. For instance, a machine designed for high-speed production may achieve 300 bottles per minute. However, this approach could lead to complications if your demand peaks at 1,000 units per day.

Furthermore, consider the scalability of your operation. A study by the Flexible Packaging Association found that 65% of businesses aim to expand production within three years. If your machinery can't adapt to future growth, investing in it might be a mistake. Opt for machines that allow adjustments to filling speeds and settings. Keeping your equipment flexible could save costs down the line.

Assessing specific needs is essential. A gap in understanding production levels can lead to over-investment or under-capacity issues. For example, a company may choose an economical model but later struggle to meet demand. Inadequate machinery can hinder growth and hurt customer satisfaction. Analyze your current and projected volumes to choose equipment wisely. Avoid decisions driven purely by price; effectiveness matters.

When selecting aerosol filling machinery, evaluating the quality and reliability of manufacturers is crucial. A trustworthy manufacturer not only provides better machinery but also ensures smoother operations. Look for manufacturers with a solid reputation in the industry. Check their history and customer reviews to gauge success and reliability.

Tip 1: Consider machinery certifications. Certifications demonstrate a commitment to quality and safety. They also reflect the manufacturer’s adherence to industry standards. A well-certified machine often ensures fewer defects and mechanical failures.

Tip 2: Request a demonstration. Observing the machinery in action can reveal its performance dynamics. It’s an opportunity to assess the operational efficiency. Machines might look polished, but they could have hidden flaws impacting productivity.

Visit manufacturing sites if possible. Watching their processes helps you understand their commitment to quality. However, be aware; not all manufacturers show their best side. Scrutinize the materials and craftsmanship. Even minor details can affect overall performance.

Understanding your needs is just as vital. Evaluate the machine’s capacity to meet your production goals. A machine with high efficiency might seem appealing, but it could exceed your current demands. Balance between performance and practicality is essential.

| Tip No. | Essential Tip | Criteria for Evaluation | Manufacturers' Reliability Rating |

|---|---|---|---|

| 1 | Assess Production Capacity | Output per hour and scalability | High |

| 2 | Check Automation Level | Degree of automation and manual intervention | Medium |

| 3 | Evaluate Ease of Maintenance | Availability of parts and service | High |

| 4 | Assess Safety Standards | Compliance with international safety regulations | High |

| 5 | Check After-Sales Support | Availability and quality of customer service | Medium |

| 6 | Evaluate Machine Customization Options | Flexibility to adapt to specific production needs | Low |

| 7 | Review User Feedback | Customer reviews and case studies | High |

| 8 | Analyze Operational Costs | Total cost of ownership and efficiency | Medium |

| 9 | Investigate Supplier Financial Stability | Company history and market presence | High |

| 10 | Ensure Compliance with Industry Standards | Industry certifications and quality assurance | High |

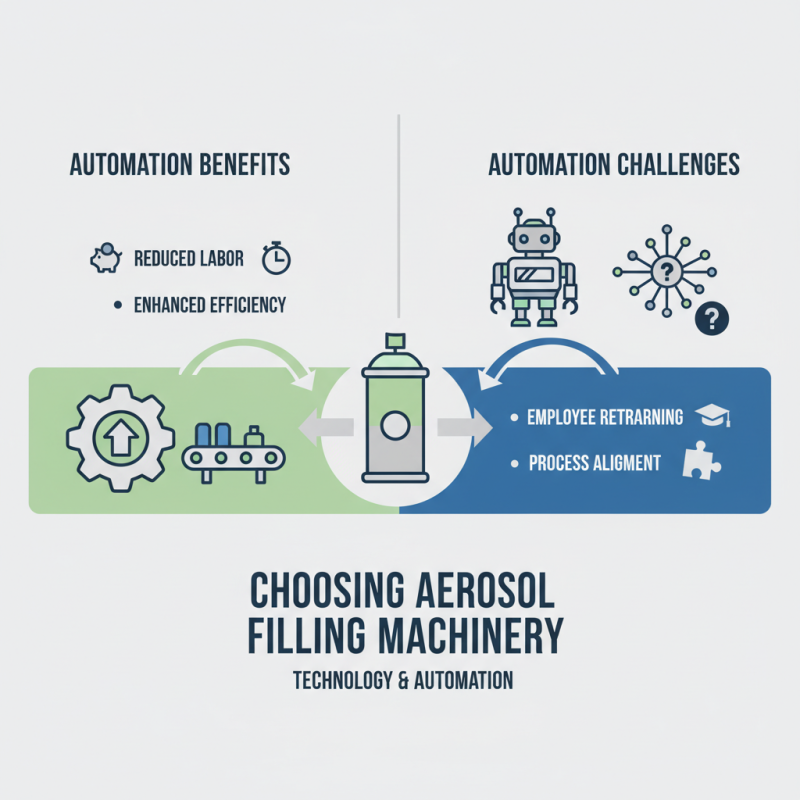

Choosing the right aerosol filling machinery involves understanding automation and technology. Automation can streamline your production. It reduces labor costs and enhances efficiency. However, automation also brings challenges. The transition may require employee retraining. Furthermore, you will need to ensure that your current processes align with new technology.

Integration of advanced technology is crucial. Look for machines with smart features. These can monitor performance in real-time and help prevent errors. Consider machinery that allows data collection for analysis. This information can lead to informed decisions. However, not all technology fulfills its promise. Sometimes, the initial setup costs are high. Balance the investment with potential returns.

When assessing machinery, think about scalability. Your business may grow, and your machines should adapt. If they can't keep up, you might face production delays. Choosing the right machinery is a reflection of your business goals. It is essential to reflect on your needs carefully. Don't rush this process. A hasty decision can cost more in the long run.

When selecting aerosol filling machinery, safety standards and compliance requirements play a crucial role. These regulations ensure the machinery operates without endangering workers or violating environmental laws. Proper certification is essential. Check if the equipment meets the required safety standards. Manufacturers should provide documentation outlining compliance. This documentation can protect businesses from penalties.

Consider the specific safety features of the machinery. Emergency shut-off switches, pressure relief valves, and proper ventilation systems are vital. Sometimes, manufacturers overlook these elements. It could lead to serious workplace accidents. Regular maintenance is necessary, but even well-maintained machines can have issues. Assessing risk factors can help businesses stay ahead of potential problems. Always prioritize safety, even if it increases initial costs.

Training employees on safety procedures is equally important. Ensure that the team understands how to operate the equipment safely. Misunderstandings can lead to dangerous situations. Regular safety drills can reinforce this knowledge. Sometimes, companies neglect this aspect. They might view it as unnecessary, but it can save lives. инвестируйте в безопасность machinery to protect your workforce.