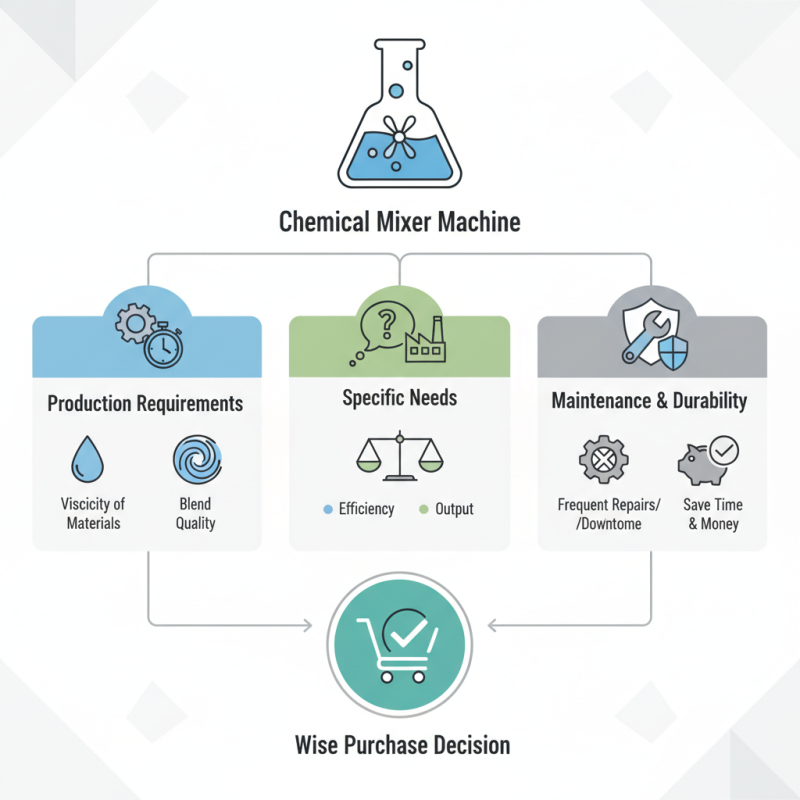

Choosing the right Chemical Mixer Machine can seem daunting. Many factors influence the decision-making process. It’s not just about price; understanding your specific needs is crucial.

A suitable Chemical Mixer Machine should fit your production requirements. Think about the viscosity of your materials and the desired blend quality. These details impact your efficiency and output.

However, one might overlook maintenance and durability. Some mixers may need frequent repairs, leading to downtime. Reflect on these factors before making a purchase. Ensuring you choose wisely can save time and money in the long run.

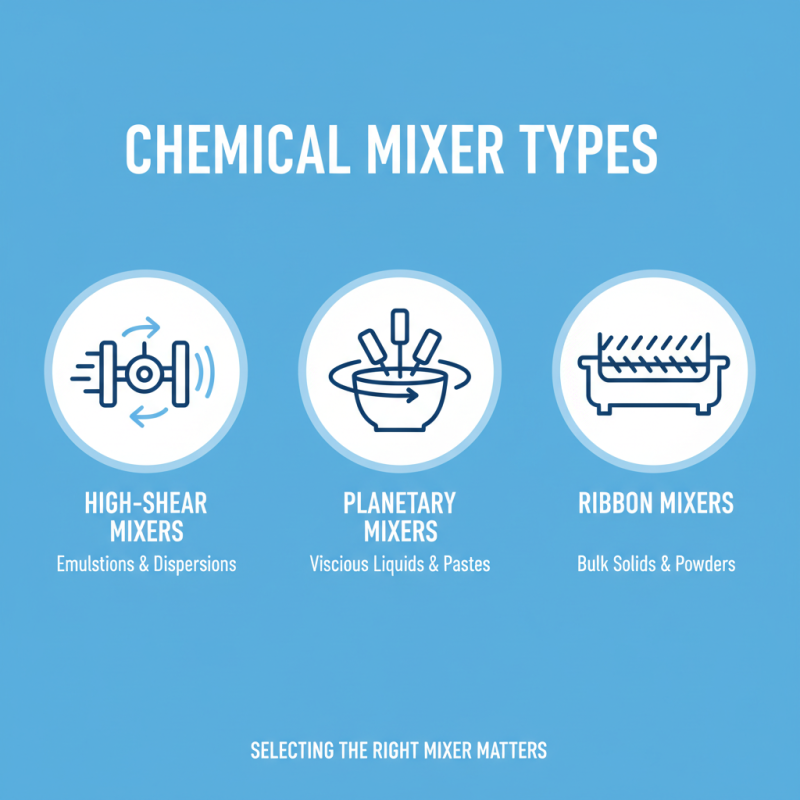

When selecting a chemical mixer machine, understanding the different types available is vital. There are several categories of mixers, including high-shear, planetary, and ribbon mixers. Each type serves specific purposes and can significantly affect the mixing process. For instance, high-shear mixers are excellent for emulsions and dispersions, while ribbon mixers are ideal for bulk solids.

High-shear mixers operate using high speeds to break down particles. They excel at creating uniform mixtures quickly. In contrast, planetary mixers rotate around a central point, ensuring a thorough blend. This type is often used for viscous materials. Ribbon mixers, on the other hand, utilize a helical ribbon that moves material toward the center and then pushes it outward. They are great for blending powders and granules but may not achieve the same level of uniformity in wet mixtures.

Choosing the right mixer can require some trial and error. Not every project will go as planned. For example, a ribbon mixer might not adequately blend a liquid-heavy formulation, leading to clumps. It's crucial to test different machines and configurations before making a final decision. Observing the mixing process and outcomes can reveal hidden issues, helping to refine your choice.

Choosing the right chemical mixer machine is essential for efficiency. It's crucial to consider several key factors when making your selection. One significant aspect is the mixer type. Different processes may require specific mixers, such as batch or continuous types. Evaluate the material being mixed as well. Some materials may need a gentle touch, while others require high shear.

Another factor is the mixer size and capacity. It's vital to ensure the size matches your production needs. An oversized mixer can waste energy, while an undersized one may not meet demand. Think about your available space, too. A machine that’s too large for your facility can lead to major workflow issues.

When reviewing options, don’t forget maintenance. A machine that’s difficult to clean or service can create downtime. Even user-friendliness is important. If operators find the mixer confusing, it can lead to mistakes. Tinkering with settings might improve outcomes, but it can also complicate processes. Keep workflows smooth and efficiency high. After careful consideration, feel confident in your choice.

Choosing the right chemical mixer machine requires careful consideration of mixer capacity and efficiency. The capacity directly impacts your production volume. If the mixer is too small, you may face delays. In contrast, an overly large mixer can lead to inefficiencies and wasted resources. Assessing your specific mixing tasks is crucial. The material type, viscosity, and desired homogeneity are key factors.

Efficiency is another important aspect. A mixer that operates slowly may not meet your deadlines. On the other hand, a machine that works too quickly can cause damage to delicate materials. It's vital to strike a balance. Often, users underestimate the need for a thorough evaluation. Frequently, the chosen machine may not be the most suitable for all tasks.

Test runs can reveal much. They can highlight flaws in mixing performance. Additionally, be aware of maintenance requirements. A machine requiring frequent repairs can lead to downtime. Always think critically about your choice. Knowing the limitations of your selected machine is essential for optimal performance.

Choosing the right chemical mixer involves understanding material compatibility and safety considerations. Different materials behave uniquely under various conditions. A report by the Processing Industry Association estimates that improper material pairing accounts for 30% of equipment failures.

Compatibility can affect the efficiency of the mixer. For example, corrosive substances may degrade certain mixer components. Materials like stainless steel are often resistant to corrosion. However, even stainless steel can fail if mixed with highly acidic solutions. Conduct proper research on materials before selection.

Safety should never be overlooked. The hazards associated with chemicals vary widely. A study shows that 40% of workplace accidents occur because of inadequate safety measures. Always consider the specific properties of chemicals involved. They may require special handling or storage conditions. Regular maintenance and inspections are essential to reduce risks. Remember, your choice in a mixer can significantly impact both performance and safety outcomes.

The following bar chart illustrates the importance of material compatibility and safety considerations when selecting a chemical mixer machine. Each aspect is critical to ensure optimal performance and minimize risks.

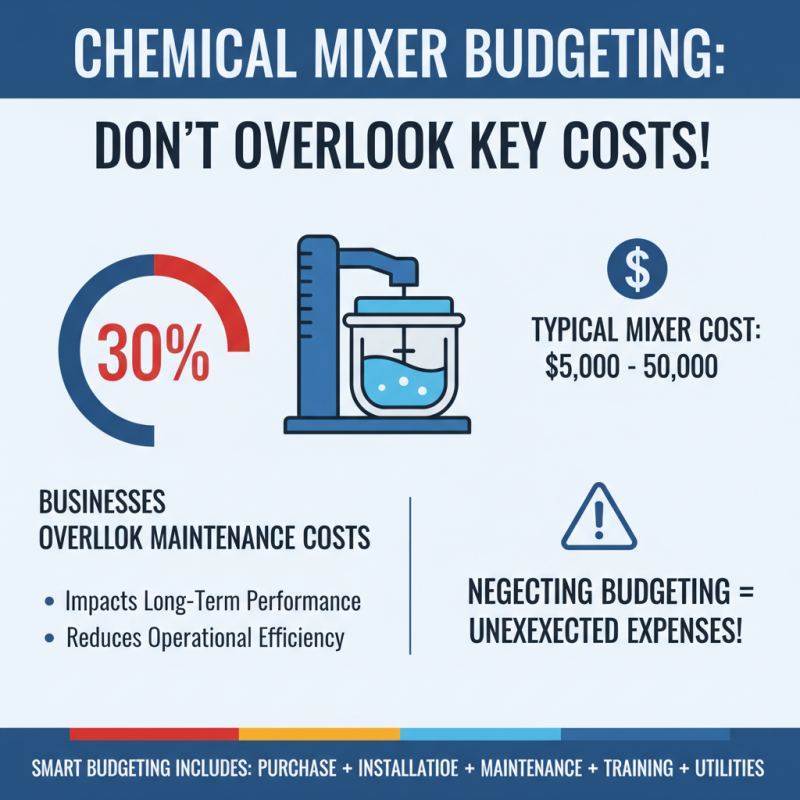

Budgeting for a chemical mixer machine can be challenging. Industry reports indicate that 30% of businesses overlook maintenance costs. These costs can significantly impact long-term performance and operational efficiency. A typical mixer may range from $5,000 to $50,000. However, neglecting proper budgeting can lead to unexpected expenses down the line.

Regular maintenance is crucial for ensuring longevity. According to a study, well-maintained equipment can last 20-30% longer. Simple tasks, like checking seals and lubrication, are often ignored. This oversight can lead to costly repairs. Companies should allocate a clear portion of their budget for routine checks. Aim for at least 10% of the initial mixer cost to ensure effective maintenance.

Many operators focus solely on the purchase price. This approach limits their understanding of the total cost of ownership. Hidden costs, such as energy consumption and downtime, add to overall expenses. Investing in high-quality machines may seem expensive but can save money over time. Reflecting on these aspects is essential for better financial decisions.