In today's rapidly evolving industrial landscape, the significance of Chemical Mixer Machines cannot be overstated. These essential devices play a critical role in ensuring the uniform incorporation of various substances, which is vital across myriad sectors, from pharmaceuticals to food production. As global markets continue to expand and diversify, the demand for advanced mixing solutions rises, prompting manufacturers to innovate and adapt their technologies to meet the unique challenges posed by different applications. This blog delves into the diverse features and applications of the best Chemical Mixer Machines available today, highlighting their transformative impact on efficiency and product quality. By exploring the latest advancements and market trends, we aim to provide insights into the future of these machines and their pivotal role in shaping industrial processes worldwide.

Choosing the right type of chemical mixer machine is crucial for achieving optimal results in various industrial applications. Different mixing processes require specific types of mixers, each designed to handle particular materials and achieve desired consistency. Factors such as viscosity, temperature sensitivity, and the nature of the ingredients play significant roles in determining which mixer is most suitable. For instance, a high-viscosity product may necessitate a planetary mixer, while a more fluid formula might be best served by a continuous mixer.

Furthermore, understanding the scale of production is vital. Batch mixers are ideal for smaller quantities or when frequent changes in formula are needed, while continuous mixers may be more efficient for large-scale production. Additionally, the materials used in the construction of the mixer should be considered, as they impact durability and compatibility with different chemicals. By carefully evaluating these factors, businesses can ensure they select a mixer that not only meets their current needs but also supports future growth and innovation in their operations.

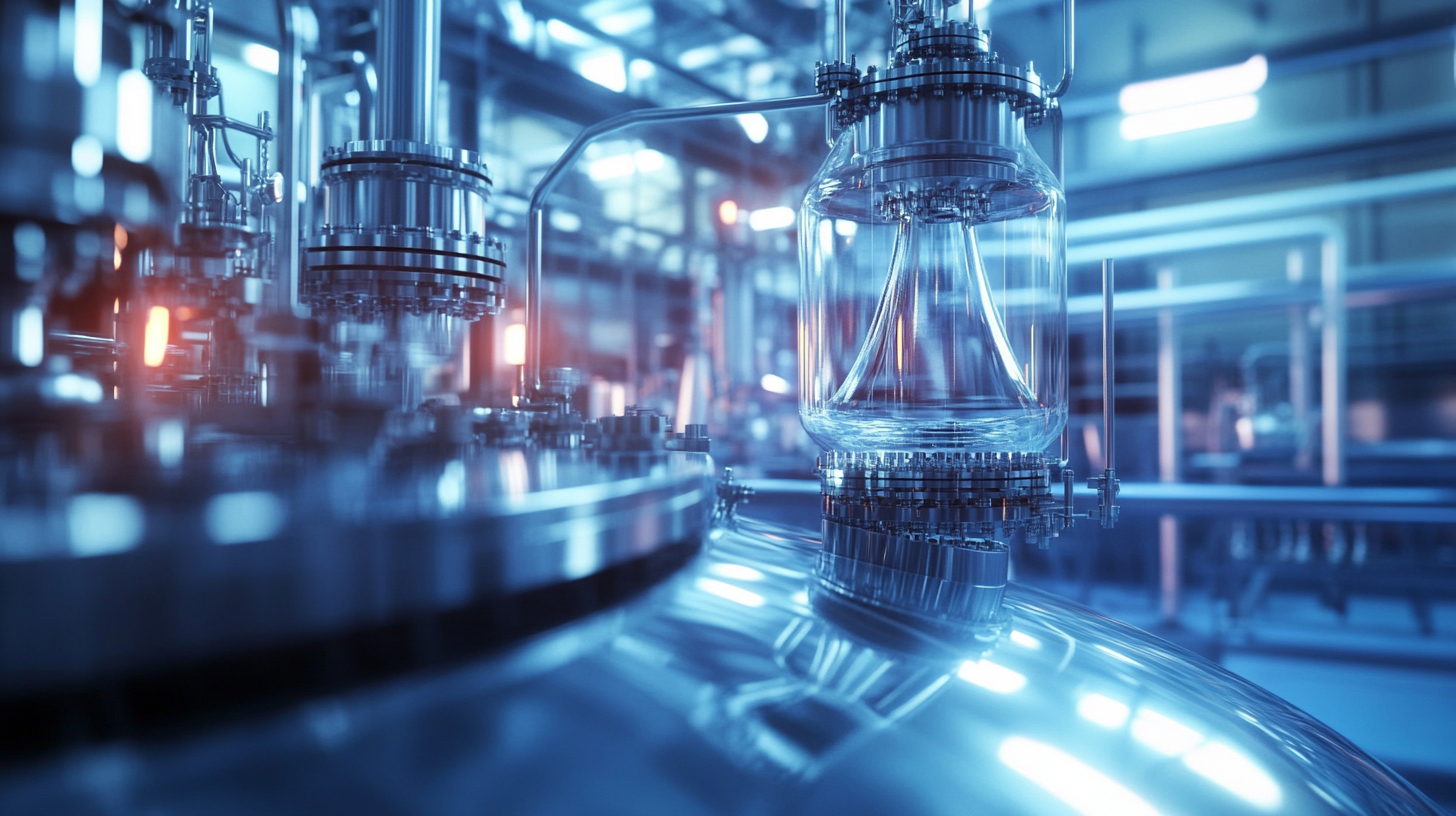

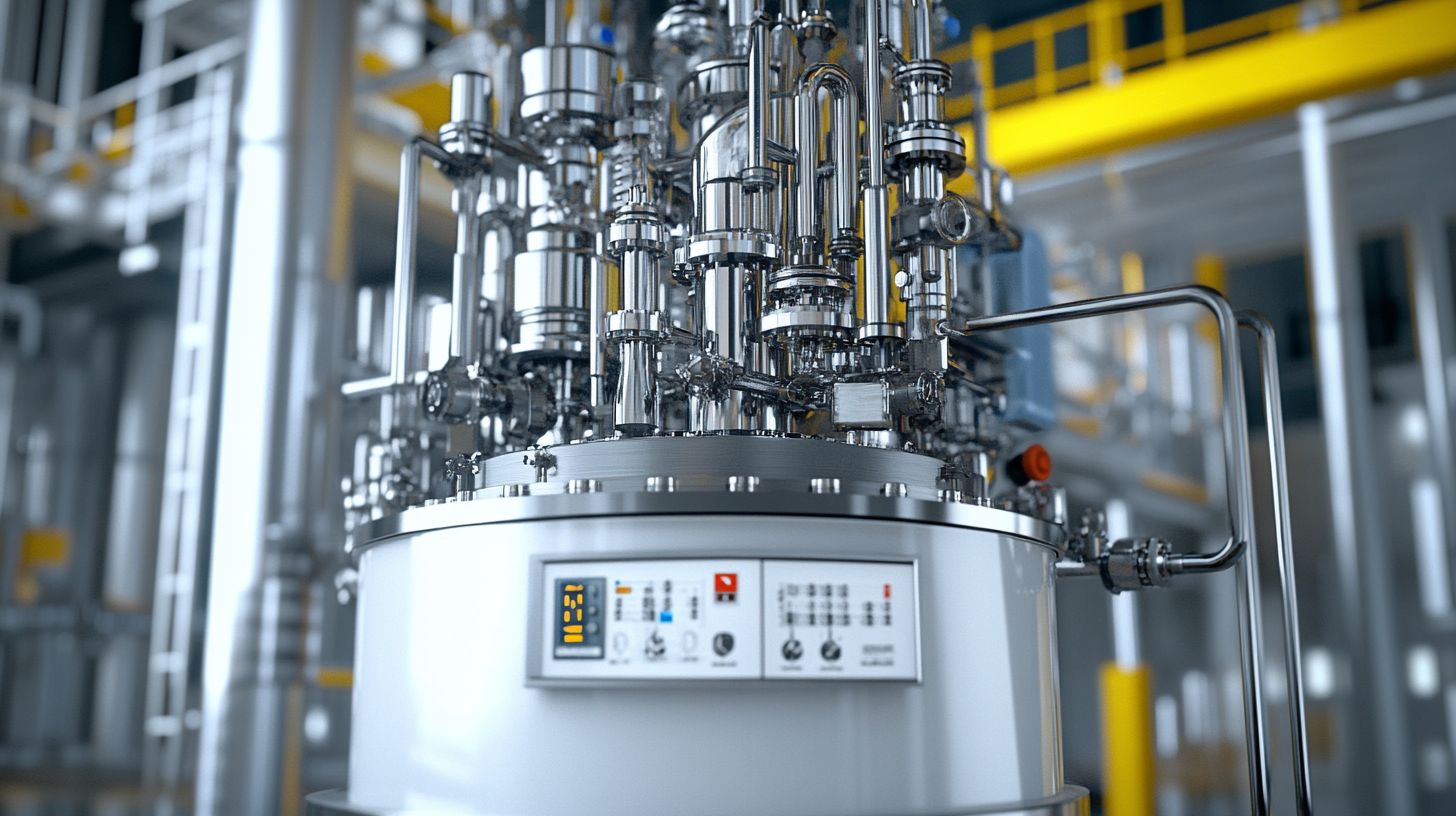

When selecting a chemical mixer machine, several key features should be taken into consideration to ensure optimal performance and efficiency. First and foremost, the mixer’s capacity and power should align with the scale of your operations. Machines with adjustable speed settings allow for greater flexibility in processing different materials, accommodating varying viscosities and ensuring a thorough mix. It's essential to assess the design of the mixing blades as well—specific shapes and configurations can significantly impact the mixing efficiency and prevent issues like dead zones where material may not be properly blended.

Another critical factor is the construction material of the mixer. Stainless steel is often preferred due to its durability, resistance to corrosion, and ease of cleaning, particularly in industries where hygiene is paramount, such as pharmaceuticals and food production. Additionally, features such as ease of maintenance, automation capabilities, and the ability to integrate with existing systems can greatly enhance operational efficiency. Ultimately, understanding the specific requirements of your application will help you make an informed choice in selecting the best chemical mixer machine available in the global market.

Chemical mixers play a crucial role across a myriad of industries, facilitating the blending of various substances to create uniform mixtures essential for production and quality control. In the pharmaceutical sector, for instance, chemical mixers are employed to combine active ingredients with excipients, ensuring proper drug formulation and efficacy. The precision and consistency provided by these machines are vital for meeting strict regulatory standards and enhancing patient safety.

In the food and beverage industry, chemical mixers are utilized to emulsify dressings, mix ingredients for sauces, and blend various flavors, contributing to the texture and taste of products. They help in achieving the desired viscosity and homogeneity, which are integral to food quality and customer satisfaction. Additionally, the cosmetic industry relies on these machines to create smooth creams and lotions, ensuring that active ingredients are evenly distributed for optimal performance.

Moreover, the agricultural sector also benefits from advanced chemical mixing technology, where mixers are used to prepare fertilizers and pesticides, ensuring even distribution of nutrients and chemicals for effective crop management. This diverse range of applications demonstrates the essential role of chemical mixers in today's global markets, enhancing efficiency and innovation across multiple sectors.

The demand for chemical mixers is closely linked to various sectors, including the global crop protection chemicals market, which is projected to reach USD 98.5 billion by 2032, growing at a CAGR of 4.3%. This increasing demand for agricultural chemicals drives the need for efficient mixing equipment to ensure uniformity and effectiveness of formulations. Different types of chemical mixers, such as high-shear mixers and ribbon blenders, play an essential role in this process, accommodating the diverse physical properties of the materials being mixed.

In the dairy processing equipment market, expected to grow from USD 10.7 billion in 2023 to USD 14.4 billion by 2028 at a CAGR of 6.2%, the application of specialized mixers enhances product consistency and quality. The ability to quickly adjust mixing parameters is vital in industries with stringent quality requirements, further underscoring the importance of selecting the right mixer type. This trend is mirrored across other markets, such as the ready-mix concrete and cocktail mixers sectors, where tailored mixing solutions are essential for meeting specific industry demands and maintaining competitive advantage.

The future of chemical mixer technology is poised for significant advancements, driven by innovative solutions aimed at enhancing efficiency and performance. As industries demand higher productivity and better quality control, manufacturers are exploring smart technology integration into mixer designs. For instance, the incorporation of Internet of Things (IoT) devices allows real-time monitoring and data collection, enabling operators to optimize mixing processes and achieve consistent results. This shift not only improves operational efficiency but also reduces material waste, aligning with the growing emphasis on sustainability in chemical manufacturing.

Another trend shaping the landscape is the development of advanced materials for chemical mixers, which enhance durability and reduce maintenance. The use of corrosion-resistant alloys and composite materials ensures that mixers withstand harsh chemical environments while maintaining peak performance. Furthermore, the rise of modular designs allows for greater flexibility and customization, enabling users to adapt their equipment to specific applications. This forward-thinking approach is revolutionizing the industry, making chemical mixer machines not only more versatile but also more aligned with the emerging needs of global markets.