In the world of emulsification, the High Shear Homogenizer stands out as a powerful tool. It’s essential for industries like pharmaceuticals, food processing, and cosmetics. According to a recent report by the International Institute of Food Engineering, approximately 40% of products require high shear mixing to achieve their desired consistency and stability. This highlights the critical role of high shear technology in enhancing product quality.

Dr. Emily Hayes, a renowned expert in food technology, emphasizes, "Understanding the use of a High Shear Homogenizer can significantly improve product formulation." Her perspective underscores the importance of proper techniques in achieving optimal results. Yet, many users overlook some key operational aspects. It's not only about selecting the right equipment but also about understanding its limitations.

Misjudging the shear rate or processing time can lead to inefficiencies. Overprocessing can cause ingredient degradation. Aspiring to perfect results often leads to frustration. Therefore, it is vital to reflect on practical experiences and adjust methods accordingly. Mastering the High Shear Homogenizer is a continuous journey, requiring patience and practice.

High shear homogenization technology plays a crucial role in many industries, including food processing, pharmaceuticals, and cosmetics. This method improves product stability and quality. It does this by reducing particle size and ensuring uniform dispersion of ingredients. Studies show that high shear homogenizers can achieve particle sizes as small as one micron, significantly enhancing ingredient absorption.

Understanding the basics is essential for optimal results. Homogenizers use high-speed rotor-stator systems to create strong vortices. This action applies mechanical shear forces to the sample. As a result, larger particles break down. This technology not only maximizes product efficacy but can also save production time. Data indicates that optimizing shear rates can lead to up to a 30% increase in product consistency.

However, it's crucial to consider some limitations. Excessive shear can heat sensitive materials, potentially leading to degradation. Monitoring temperature during this process is vital. Operators must also think about the viscosity of the mixture. Not all formulations respond equally to shear forces. Fine-tuning these parameters is necessary for the best outcomes. Understanding the intricacies of this technology can lead to improved performance and better product results.

| Parameter | Description | Optimal Value |

|---|---|---|

| Shear Rate | The speed at which the fluid is subjected to shear; determines particle size reduction. | 5000 - 25000 s-1 |

| Viscosity | Resistance to flow; affects how the product homogenizes. | < 2000 cP |

| Temperature | The thermal condition of the material; can affect consistency and processing time. | Room Temperature (20-25°C) |

| Processing Time | Duration for which material is processed. | 5 - 15 minutes |

| Batch Size | Volume of material to be homogenized in one run. | 1 - 1000 liters |

A high shear homogenizer is essential for achieving uniformity in mixtures. Its key components include a rotor, stator, and motor. The rotor spins at high speeds, generating shear forces that break down particles and create a smooth emulsion or suspension. The stator surrounds the rotor, guiding the fluid flow and enhancing the mixing efficiency. The motor powers the rotor and needs to be robust enough for the task.

Tips for selecting the right shear rate are crucial. It impacts the final texture of your product. A high shear rate can create finer emulsions, while a lower rate may retain some larger particles. Experimenting with different settings is vital. Keep in mind that not every batch requires the same approach. Observe the mixture carefully to adjust the parameters.

Consistency is essential, but sometimes it can be elusive. Variations in material properties can lead to different outcomes. Keeping a detailed log of settings and results can help troubleshoot these issues. Be open to revisiting your methods, as minor changes can significantly impact the final product. Balancing efficiency and quality often requires careful consideration.

Selecting the right homogenization parameters is crucial for achieving optimal results with a high shear homogenizer. The viscosity of the material is a key factor. Materials with high viscosity require adjustments in shear force and processing time. For example, a study highlighted that a slight increase in shear rate can improve particle dispersion significantly, achieving even particle sizes down to 1 micron. However, this may also lead to overheating, which can alter the material properties.

Another important consideration is the frequency of homogenization cycles. Research indicates that multiple cycles can be beneficial. Each cycle breaks down the particles further, but there's a diminishing return. After a certain point, additional cycles may cause more damage than improvement. Manufacturers often recommend adjusting parameters iteratively based on the material's specific response.

Moreover, mixing times should not be uniform across all materials. Some materials require longer mixing to achieve uniformity, while others can be homogenized quickly. It's important to monitor the process closely and validate results. A poorly set parameter can lead to inconsistency, which can impact the final product quality. Make sure to document each trial and learn from deviations.

This bar chart illustrates the suggested parameters for achieving optimal results when using a high shear homogenizer. Key factors include Speed (RPM), Time (min), Viscosity (mPa·s), and Temperature (°C).

Operating a high shear homogenizer effectively requires attention to detail. For optimal results, maintaining the right shear rate is crucial. Studies show that shear rates between 5,000 to 20,000 s⁻¹ yield the best homogenization for emulsions. This range ensures uniform size distribution, which impacts product stability.

Tip: Always monitor the viscosity of your material. Higher viscosity can lead to ineffective mixing and increased wear on the machine.

Temperature control is another important factor. Keeping the process temperature stable enhances the quality of the final product. When the temperature rises, it may affect the viscosity and lead to challenges in emulsification. Research indicates that variations in temperature can result in inconsistencies in the final product.

Tip: Use a thermometer or temperature sensor to track changes in real-time. This ensures you can make immediate adjustments.

Regular maintenance checks can prevent issues before they arise. Failing to clean the homogenizer frequently can lead to product contamination or performance degradation. Reports suggest that weekly cleaning enhances longevity and performance efficiency.

Tip: Develop a cleaning schedule. Stick to it to avoid last-minute scrambles that can compromise quality.

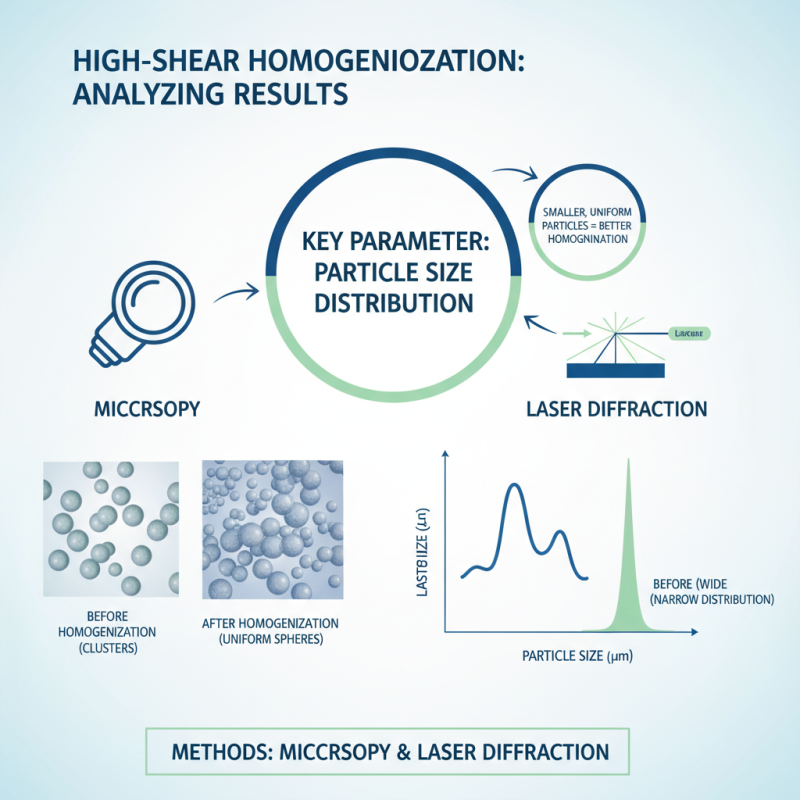

When using a high shear homogenizer, analyzing results is crucial. Several parameters can help assess homogenization success effectively. Particle size distribution is key. Smaller, uniform particles mean better homogenization. The process can be observed through microscopy or using laser diffraction techniques.

Viscosity changes should also be noted. A successful homogenization reduces viscosity, making mixing easier. However, if you notice unexpected viscosity levels, it might indicate inadequate processes or a need to adjust shear rates. Keep track of these details. They help understand whether your method is effective or needs adjustment.

Tips: Always calibrate the homogenizer before use. This helps ensure consistency in your results. Monitor temperature during the process too. High temperatures can affect sample integrity. Lastly, document your settings and outcomes clearly. This reflection can guide future experiments. Adjusting parameters allows for continuous improvement in homogenization techniques.