Choosing the right Agitator Mixing Tank can be a daunting task. Industry expert John Smith says, "The right tank can enhance efficiency and reduce operational costs." His insights highlight the importance of proper selection.

When evaluating Agitator Mixing Tanks, consider your specific needs. Think about the viscosity of the materials you’ll be mixing. Also, consider the volume required for your applications. Details matter here.

Many overlook the design and configuration of these tanks. A poorly chose tank can lead to inefficiencies. Not all agitators are created equal. Mistakes in selecting the right one can impact productivity. Reflecting on these factors is essential for success.

Agitator mixing tanks are essential for various industries. They ensure that materials are homogeneous and meet required specifications. Understanding how these tanks work is crucial for making informed choices.

Different agitator designs serve specific functions. For instance, a high-shear mixer is great for emulsifying substances quickly. Conversely, a tank with a simple propeller may be more suitable for blending low-viscosity liquids. According to a recent industry report, proper agitation can improve mixing efficiency by up to 40%. This statistic highlights the importance of selecting the right equipment for your needs.

Tips: Always consider the viscosity of your materials. Higher viscosity requires more power to mix effectively. Don’t overlook tank shape; it significantly affects flow patterns. Sometimes, a larger tank isn't better. If your application requires precision, a smaller, well-designed tank might be more effective.

Choosing the right agitator tank can be complex. You must evaluate your specific mixing needs carefully. Sometimes, trial and error is unavoidable. Remember, not all solutions are one-size-fits-all. A deep understanding of agitation can aid in optimizing processes and improving overall productivity.

| Tank Size (Gallons) | Material Type | Agitator Type | Motor Power (HP) | Applications |

|---|---|---|---|---|

| 50 | Stainless Steel | Anchor Agitator | 2 | Paints, Coatings |

| 100 | Carbon Steel | Turbine Agitator | 5 | Food & Beverage |

| 200 | Polypropylene | Paddle Agitator | 10 | Chemicals |

| 500 | FRP | Gear Agitator | 15 | Wastewater Treatment |

| 1000 | Stainless Steel | Hydraulic Agitator | 20 | Pharmaceuticals |

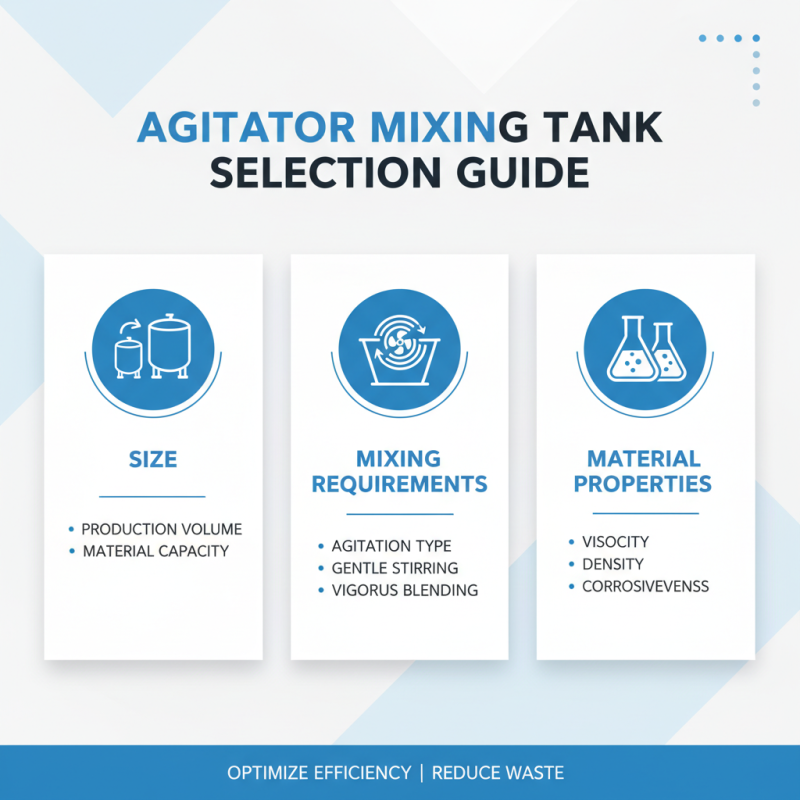

When selecting an agitator mixing tank, it's crucial to assess your specific mixing requirements and applications. Start by identifying the type of materials you will mix. Are they viscous or liquid? Will you need a gentle or vigorous mixing action? These factors play a significant role in the design and type of agitator you should consider.

Next, think about the desired outcome of your mixing process. Are you aiming for homogeneity or a specific particle size reduction? This is where a detailed understanding of your application becomes essential. Sometimes, choosing the right tank may not be straightforward. You might need to experiment with several configurations to see what works best. Keep in mind that trial and error could lead to unexpected results.

Finally, don’t overlook tank capacity. A tank that is too small might lead to frequent batch changes. Conversely, a tank that is too large can waste resources and energy. Reflecting on these points can help in making a more informed decision. Always remember that an ideal solution often requires a balance of various factors specific to your unique mixing task.

When selecting an agitator mixing tank, several key factors come into play. The size is crucial. Think about your production needs. A tank that is too small will cause inefficiencies. Alternatively, a tank that is too large may waste resources. Consider the volume of material you handle. Understand your mixing requirements. Different processes need different types of agitation. Some require gentle stirring, while others need vigorous mixing.

The material of the tank is another important aspect. Corrosion resistance is vital for durability. Stainless steel is popular, but not always necessary. It depends on the nature of your products. Additionally, the design of the agitator affects performance. Paddle, turbine, or anchor types each have specific functions. Choose one based on your application. Sometimes, a less common design works better for unique situations.

Lastly, examine the power of the agitator. The motor's specifications will determine its efficiency. Often, underpowered units struggle to mix effectively. Moreover, overpowered units can introduce air bubbles, complicating the process. It’s essential to find a balance. Test different setups when possible. This trial and error can lead to better outcomes. Selecting the right agitator tank is not merely a mechanical choice; it's a critical decision that impacts efficiency and quality.

When selecting an agitator mixing tank, understanding the types of agitators is crucial. Different agitator designs can significantly influence mixing efficiency. For instance, a recent industry report highlighted that turbine agitators can achieve a 65% faster mixing time compared to other types. This is pivotal for processes that rely on quick and uniform blending.

The choice of agitator depends heavily on the material being mixed. For highly viscous fluids, helical ribbon agitators are often recommended. These can provide a more effective flow pattern and reduce dead zones. Studies indicate that using the wrong agitator can lead to inefficiencies, impacting yield. In one study, mismatched agitators resulted in a 30% increase in batch processing time.

However, it's not just about speed. Mixing uniformity is essential too. Some designs, like anchor mixers, may offer slower but more uniform results. A balance between speed and consistency is necessary. Overemphasis on one aspect might lead to suboptimal mixing quality. It's important to reflect on these factors while choosing the right agitator. The implications of poor decisions in this area can be significant for production.

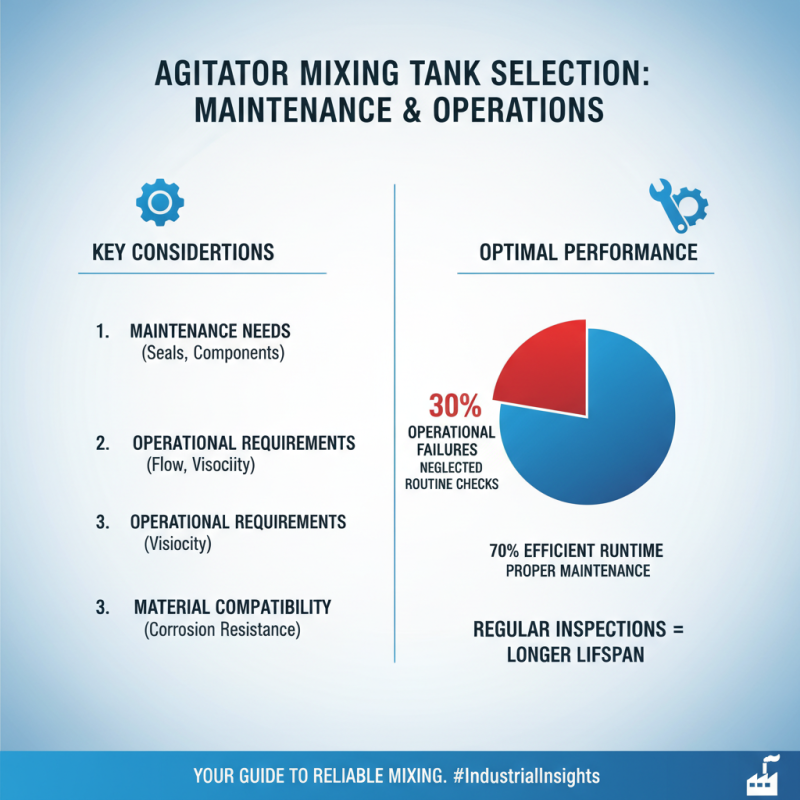

Choosing the right agitator mixing tank involves careful consideration of maintenance and operational needs. Regular maintenance is crucial for optimal performance. According to industry reports, 30% of operational failures stem from neglecting routine checks. Inspect seals and components frequently to avoid leaks.

Tips: Schedule monthly inspections. Look for wear on agitator blades. Replace them when needed.

Operational efficiency can be affected by improper mixing. Ineffective mixing leads to product inconsistencies. In fact, studies show that up to 25% of a batch may be rejected due to poor mixing quality. Proper tank size and agitator design play significant roles here.

Tips: Ensure your tank matches your production volume. A tank too small can cause agitation issues.

Maintaining accurate temperature and viscosity is also vital. Equipment must be calibrated regularly. Failure to do so can lead to safety risks and product loss. Even small discrepancies can significantly alter product outcomes.

Tips: Document temperature and viscosity checks. Set reminders for calibration schedules.