In the rapidly evolving landscape of manufacturing and processing industries, the role of a Liquid Mixer Machine has become increasingly pivotal. As noted in a recent report by the International Society for Mixing Technology, the global liquid mixing market is projected to reach approximately $4 billion by 2025, highlighting the critical importance of these machines in various applications, from food production to chemical processing. The efficiency and effectiveness of a Liquid Mixer Machine can significantly impact product quality, consistency, and overall operational performance.

Industry expert Dr. Emily Turner, a leading authority on mixing technologies, emphasizes the transformative potential of these machines, stating, "A Liquid Mixer Machine not only enhances product uniformity but also optimizes energy consumption, providing manufacturers with a competitive edge." As industries strive for higher productivity and quality, understanding the mechanics and functionalities of Liquid Mixer Machines becomes essential. This article aims to provide insights into the workings of these machines, their various applications, and how they can be tailored to meet specific operational needs, thereby helping businesses achieve their production goals in a cost-effective manner.

A liquid mixer machine is an essential piece of equipment used across various industries to ensure the homogeneity of liquid products. It typically comprises a mixing tank, an agitator or mixer blade, and an energy source. These machines can handle a wide range of liquids, including viscous substances, emulsions, and suspensions.

According to industry reports, the global liquid mixer market is anticipated to grow significantly, reaching a valuation of approximately USD 4 billion by 2025, driven by increasing demand in sectors such as food and beverages, pharmaceuticals, and chemicals.

The operation of a liquid mixer machine can vary based on the complexity needed for the mixing process. In general, the mixer creates turbulence, allowing different liquids to blend effectively. The efficiency of this process is crucial; for instance, studies show that proper mixing can reduce processing time by up to 30%, maximizing productivity.

Furthermore, the configuration of the mixer blades and the design of the tank play a critical role in achieving the desired consistency and properties of the final product. Manufacturers must take into account the specific viscosity and density of the materials to optimize their mixing technology for better results.

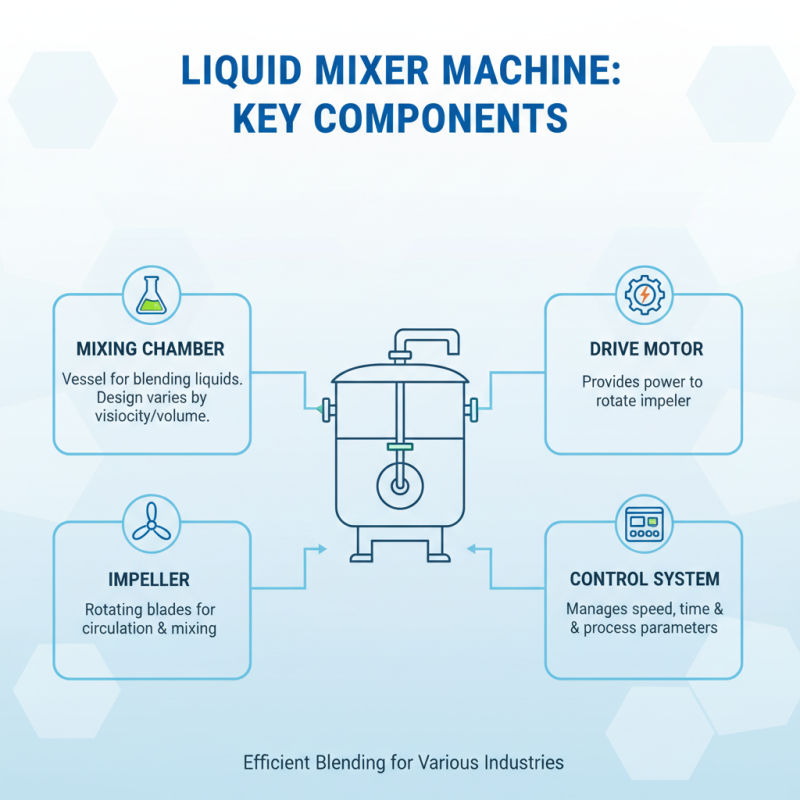

A liquid mixer machine is an essential piece of equipment in various industries, designed to blend different liquids efficiently. Understanding the key components of this machinery is crucial for maximizing its functionality and performance. The primary elements typically include the mixing chamber, impeller, drive motor, and control system. The mixing chamber serves as the vessel where liquids are combined, allowing for the effective blending of ingredients. Its design can vary depending on the viscosity and volume of the materials involved.

The impeller is a vital part of the liquid mixer, responsible for creating fluid motion within the chamber. Different types of impellers can be utilized depending on the mixing requirements, such as axial flow for gentle mixing or radial flow for more intense processes. The drive motor powers the impeller and can be adjusted to change the speed and intensity of the mixing, catering to the specific needs of different applications. Lastly, the control system plays a crucial role in monitoring and adjusting the mixing parameters for optimal performance.

Tips: When selecting a liquid mixer machine, consider the type of materials you will be mixing and the desired end product characteristics. Ensuring compatibility between the mixer components and the liquids is vital. Regular maintenance of the equipment is also essential for sustaining its efficiency and prolonging its lifespan.

Liquid mixer machines play a crucial role in various industries by efficiently blending liquids to achieve desired consistency and homogeneity. These machines operate on the principle of mechanical mixing, which involves the use of impellers or agitators to create movement within the mixture, facilitating uniform distribution of components. The specific design of the impeller can greatly influence the mixing process, impacting factors such as shear rates and flow patterns, which are essential in applications ranging from food and beverage production to chemical processing.

According to industry reports, the global liquid mixer market is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 5.7% from 2021 to 2026. The effectiveness of liquid mixers is often measured by their ability to reduce mixing time and improve product quality. Advanced liquid mixer machines incorporate technologies such as variable speed drives and automated control systems, allowing for precise adjustment of mixing parameters. Studies indicate that optimizing these parameters can lead to a 30% reduction in energy consumption while enhancing operational efficiency.

Liquid mixer machines also employ various mixing techniques, including batch and continuous mixing, each suited for different applications. Batch mixers are ideal for smaller volumes where product variability is essential, while continuous mixers are designed for high-volume production, providing consistent results over an extended period. By understanding the distinct operational capabilities of these machines, businesses can better meet their processing needs and improve their overall production efficiency.

This chart compares the performance metrics of two different liquid mixer machines. The parameters include capacity in liters, mixing speed in RPM, power consumption in kW, and weight in kg. Choose the right mixer based on your specific operational needs.

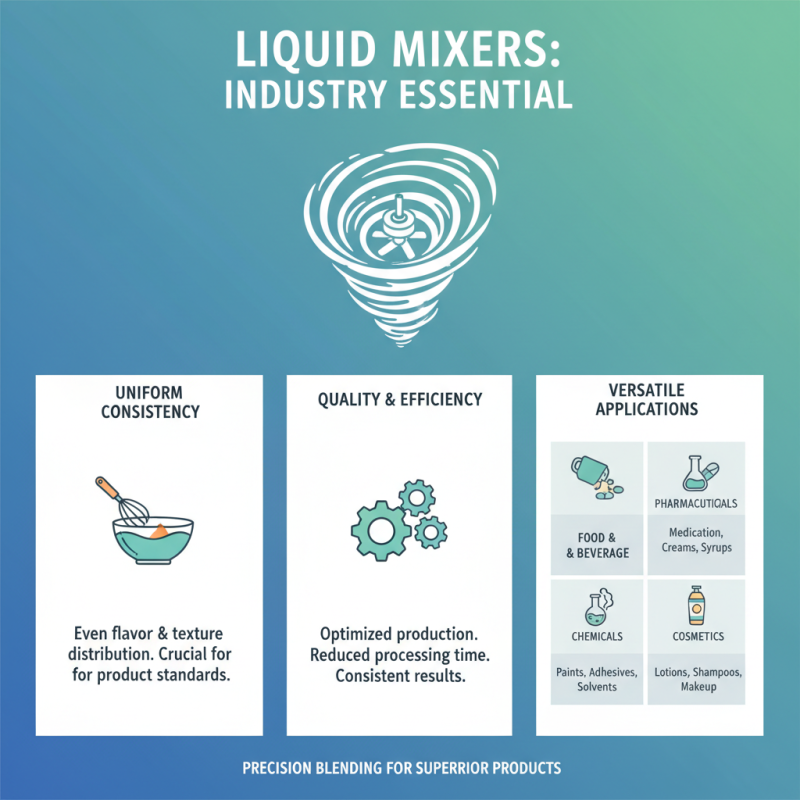

Liquid mixer machines play a vital role across a multitude of industries, enhancing the quality and efficiency of production processes. In the food and beverage sector, these machines are essential for achieving uniform consistency in products like sauces, dressings, and beverages. By effectively blending ingredients, liquid mixers ensure that flavors and textures are evenly distributed, which is crucial for meeting consumer expectations and maintaining product standards. The precise mixing capabilities also enable manufacturers to achieve specific formulations, catering to dietary requirements or preferences.

In the chemical industry, liquid mixer machines are used to create homogenous mixtures of solvents, additives, and reactants. This is particularly important in processes such as pharmaceuticals and cosmetic production, where the stability and efficacy of the final product depend on thorough mixing. Additionally, in the agricultural sector, these machines assist in creating liquid fertilizers and pesticides, ensuring that active ingredients are evenly dispersed for optimal effectiveness. The versatility of liquid mixer machines makes them indispensable in various applications, driving innovation and efficiency across different fields.

Liquid mixer machines play a crucial role in various industries, particularly for blending liquids to achieve desired consistency and homogeneity. One of the primary benefits of using a liquid mixer machine is its efficiency in processing large volumes of liquids. According to a report by Grand View Research, the global mixer market size is expected to reach USD 7.5 billion by 2025, propelled by the rising demand in the food and beverage sector, where consistent product quality is vital. The automation of mixing processes can significantly reduce labor costs and production time, allowing manufacturers to respond quicker to market demands.

Furthermore, liquid mixers enhance product quality and consistency by ensuring thorough blending, which is essential in maintaining the taste and texture of food products, as well as the effectiveness of chemical formulations. The Fidgeon Group highlighted in their analysis that many industries benefit from reduced waste and improved product uniformity when employing liquid mixers, leading to increased customer satisfaction and loyalty. Additionally, advanced technologies in mixer design, such as stirring mechanisms and adjustable speed controls, allow for greater precision in mixing, catering to specific formulation requirements across various applications.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Mixing Capacity | Ranges from small batches to large industrial quantities. | Versatile for different production scales. | Food processing, pharmaceuticals, cosmetics. |

| Types of Mixers | Includes paddle mixers, ribbon mixers, and turbine mixers. | Customized mixing solutions for various materials. | Industrial mixing, chemical processing. |

| Energy Efficiency | Designed to use less energy while providing optimal mixing. | Reduces operational costs. | Manufacturing, agrochemicals. |

| Maintenance | Easy to clean and maintain, ensuring durability. | Minimizes downtime and maintenance costs. | Cosmetology, food additive production. |

| Mixing Speed | Variable speeds to accommodate different mixing requirements. | Enhances mixing efficiency and product consistency. | Pharmaceuticals, beverages. |