In the rapidly evolving landscape of industrial manufacturing, the significance of efficient mixing processes cannot be understated, particularly when it comes to the performance of the Chemical Mixer Machine. According to recent industry reports, the global market for chemical mixing equipment is projected to reach over $7.5 billion by 2025, growing at a CAGR of 4.5%. As industries strive for enhanced productivity and reduced operational costs, the optimization of chemical mixing processes presents a vital opportunity. Advanced Chemical Mixer Machines equipped with cutting-edge technology can improve consistency and quality while minimizing waste, thereby reinforcing their pivotal role in sectors such as food, pharmaceuticals, and materials. By uncovering the secrets behind these sophisticated machines, organizations can harness their potential to drive industrial efficiency and gain a competitive edge in the market.

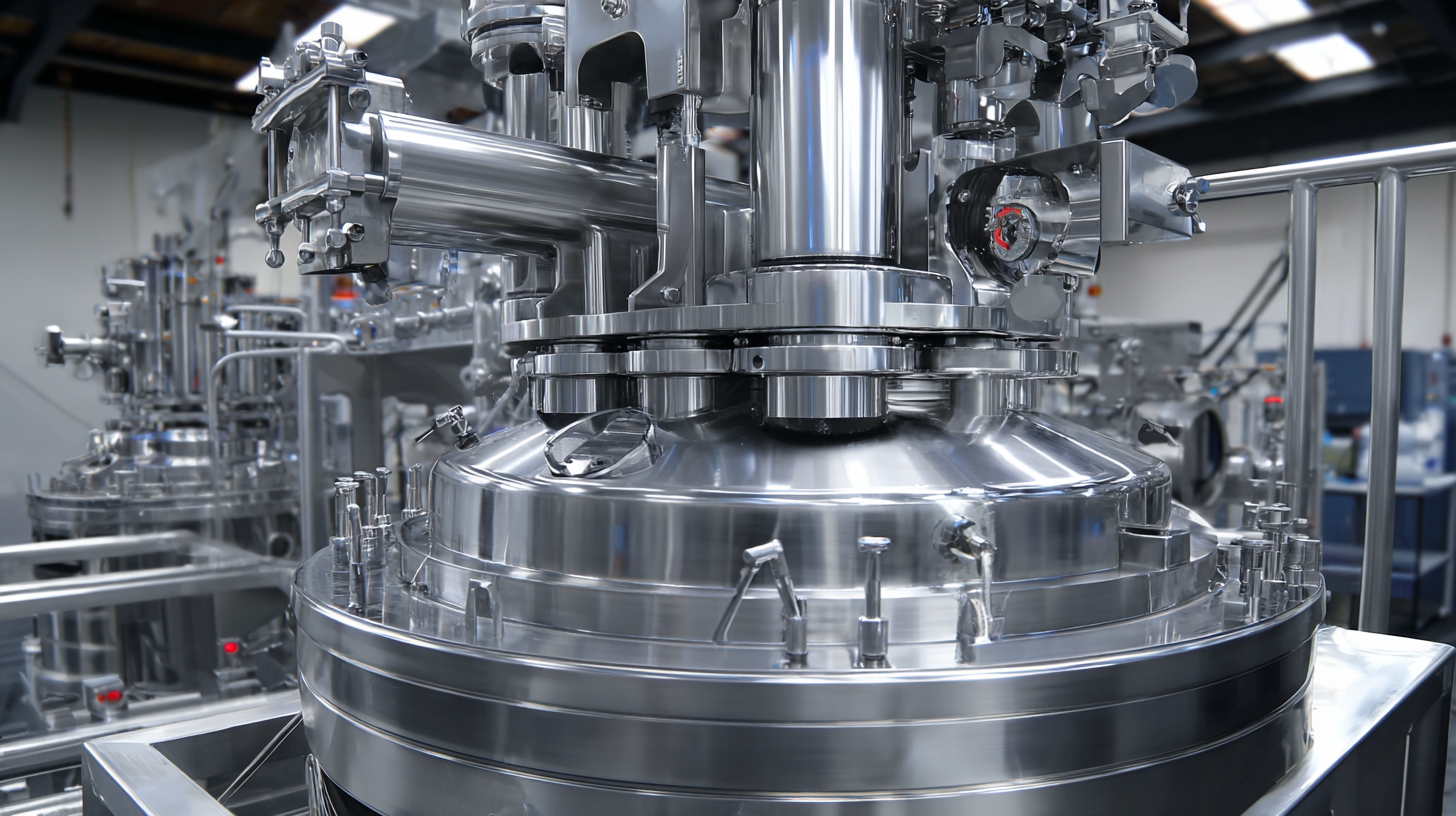

Chemical mixer machines play a crucial role in various industries, from pharmaceuticals to food processing, making the understanding of their basic components essential for optimizing production efficiency. The primary components include the mixing chamber, agitation system, and drive mechanism. The mixing chamber is designed to accommodate different viscosities and volumes, with common configurations like batch or continuous mixers. According to a recent report from Research and Markets, the global market for industrial mixers is projected to reach $9.92 billion by 2025, reflecting the growing demand for efficient mixing solutions.

Chemical mixer machines play a crucial role in various industries, from pharmaceuticals to food processing, making the understanding of their basic components essential for optimizing production efficiency. The primary components include the mixing chamber, agitation system, and drive mechanism. The mixing chamber is designed to accommodate different viscosities and volumes, with common configurations like batch or continuous mixers. According to a recent report from Research and Markets, the global market for industrial mixers is projected to reach $9.92 billion by 2025, reflecting the growing demand for efficient mixing solutions.

The agitation system, often comprising blades, paddles, or impellers, is central to achieving uniform mixtures. The choice of agitation type directly impacts mixing efficiency, as different designs allow for variations in shear, flow patterns, and energy consumption. In fact, a study by the American Institute of Chemical Engineers revealed that optimizing mixer design could enhance process efficiency by up to 25%, leading to significant cost savings. Lastly, an effective drive mechanism ensures that the agitation system operates smoothly at the desired speeds and torque levels, essential for maintaining product quality and consistency across batches. Understanding these components and their interactions not only aids in selecting the right mixer but also plays an integral role in boosting overall industrial productivity.

The effective mixing of materials is crucial for achieving optimal outcomes in various industrial applications. Recent industry reports highlight that proper mixing techniques can reduce production costs by up to 30%, while simultaneously enhancing the quality of the final product. According to a study conducted by the International Journal of Chemical Engineering, approximately 60% of production issues stem from inadequate mixing, indicating a pressing need for businesses to adopt advanced mixing methods.

Among the most effective mixing techniques is the use of high-shear mixers, which have gained popularity in industries ranging from pharmaceuticals to food processing. These mixers improve the uniformity of the final product and can reduce mix time by nearly 50%. Furthermore, the integration of digital monitoring systems allows for real-time adjustments, ensuring consistency and higher yield rates. The 2023 Global Mixing Equipment Market Report predicts that the adoption of sophisticated mixing technologies will grow annually by 5.7%, emphasizing the importance of staying updated with these techniques to maintain competitive advantage in the marketplace.

Optimizing operating parameters in chemical mixer machines is crucial for enhancing mixing efficiency and ultimately improving overall industrial productivity. According to a report by Research and Markets, the global market for mixing equipment is expected to grow significantly, reaching $5.28 billion by 2025. A key factor driving this growth is the demand for efficient mixing processes that minimize waste and reduce energy consumption. A well-tuned mixer can lead to a reduction in processing times by up to 30%, allowing industries to meet increasing production demands without sacrificing quality.

One of the critical operating parameters to consider is the agitation speed, which can significantly affect the homogeneity of the mixture. A study published in the Journal of Chemical Engineering revealed that varying the mixing speed by just 10% could result in a 25% improvement in mixing uniformity. Additionally, the configuration of the mixer, including blade design and tank geometry, plays a vital role in achieving optimal results. High-efficiency mixers designed with advanced materials and technologies can operate at lower speeds while delivering superior mixing performance, thereby reducing energy requirements.

By fine-tuning these parameters, industries can enhance the performance of their chemical mixer machines and achieve better outcomes in their production processes.

Maintaining chemical mixer machines is crucial for enhancing industrial efficiency and extending equipment lifespan. According to a report by the International Society for Pharmaceutical Engineering, proper maintenance can increase equipment utilization rates by over 30%. Regular checks on components such as impellers and seals ensure optimal performance and prevent costly downtimes. It is recommended to implement a predictive maintenance schedule that utilizes data analytics to foresee potential failures, thus addressing issues before they escalate.

Additionally, lubrication is a key aspect of maintenance that should not be overlooked. The Machinery Lubrication article notes that inadequate lubrication can lead to a significant increase in wear and tear, reducing the life of mechanical parts by up to 50%. Adopting lubrication best practices, including the use of high-quality lubricants and following manufacturer guidelines, can vastly improve operational efficiency. Furthermore, routine cleaning of mixer parts helps prevent contamination that can adversely affect product quality, making it a fundamental part of maintenance protocols in the chemical industry.

In recent years, innovative technologies have emerged to revolutionize the chemical mixing processes, leading to significant enhancements in industrial efficiency. Advanced automation and control systems have enabled precise monitoring of mixing conditions, ensuring that recipes are followed with pin-point accuracy. These systems utilize sensors and real-time data analytics to optimize the mixing parameters, such as speed, temperature, and time, thereby minimizing human error and maximizing productivity.

Moreover, the integration of artificial intelligence in chemical mixer machines is transforming how industries approach formulation and quality control. AI algorithms can predict mixing outcomes based on historical data, enabling manufacturers to make informed adjustments to processes quickly. Furthermore, new materials and designs in mixer construction are contributing to better performance and less downtime. The development of high-shear and inline mixers allows for faster and more effective blending of a diverse range of materials, thus driving innovation and efficiency in various sectors from pharmaceuticals to food processing.