Selecting the right Chemical Mixer Machine is crucial for efficiency and productivity in various industries. According to a recent market report, the global demand for chemical mixers is expected to increase by 6.5% annually. This growth stems from sectors like pharmaceuticals, food processing, and cosmetics, where consistent mixing quality is vital.

When choosing a Chemical Mixer Machine, consider key features such as capacity, blending speed, and material compatibility. A mismatched machine can affect product quality and production costs. Industry experts suggest that improper selection could lead to a 20% increase in operational expenses.

Additionally, proper maintenance and operation are essential for maximizing the lifespan of your mixer. Many facilities overlook this, which can lead to frequent downtimes. Evaluating the market can be overwhelming, and not all manufacturers offer reliable equipment. Therefore, thorough research is necessary to avoid costly mistakes in your investment.

When selecting a chemical mixer machine, several factors should be considered. The type of materials you plan to mix is crucial. Different chemicals have varying properties. A machine that works well with one type may not work effectively with another. Pay attention to viscosity levels. Some substances are thicker than others, requiring specialized equipment.

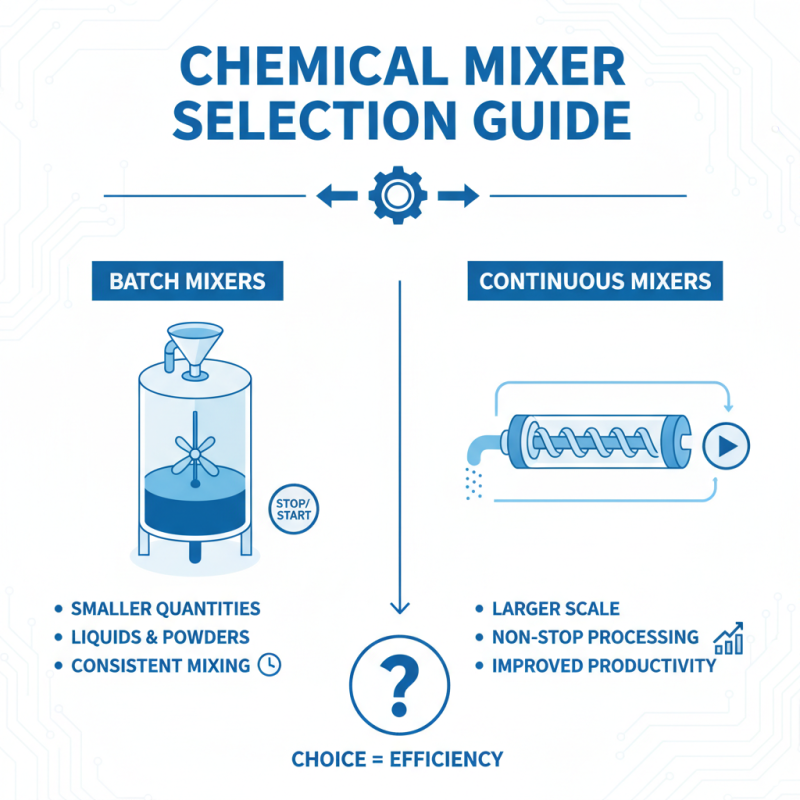

Another important factor is the mixing method. Options include batch mixing and continuous mixing. Batch mixers are great for smaller quantities. However, they might not be ideal for large-scale operations. Continuous mixers offer efficiency for greater volumes but could have a higher initial cost.

Finally, consider the machine's maintenance requirements. Some mixers demand frequent upkeep, which can lead to downtime. Think about the technical support and spare parts availability. A reliable machine with good support is essential for smooth operations. Sometimes, overlooked details can have significant impacts on productivity, so don’t rush this decision.

| Factors | Description | Recommended Features |

|---|---|---|

| Mixing Capacity | The volume of material that the mixer can accommodate at one time. | Choose based on production needs, typically measured in liters or gallons. |

| Type of Mixer | The particular design of the mixer that affects mixing efficiency. | Consider paddle mixers, ribbon mixers, and high-shear mixers based on application. |

| Material Compatibility | The ability of the mixer to handle various chemical compositions safely. | Select materials that resist corrosion and can withstand chemical reactions. |

| Power Requirements | The energy needed for operation, often tied to the mixer’s speed and efficiency. | Evaluate energy consumption and choose energy-efficient models. |

| Ease of Maintenance | How easy it is to clean and maintain the machine for long-term use. | Look for mixers with simple disassembly and easy access to parts. |

| Safety Features | Integrated safety measures to protect operators and equipment. | Select mixers with emergency shutdown systems and protective enclosures. |

| Cost | The total investment required for purchase and installation. | Consider both upfront costs and long-term operational savings. |

Choosing the right chemical mixer machine is crucial for operational efficiency. Various types of mixers are available, each designed for specific applications. For instance, batch mixers are ideal for smaller quantities. They ensure consistent mixing of liquids and powders. Continuous mixers, however, cater to larger-scale operations. They process materials non-stop, which improves productivity.

According to a recent industry report, the global chemical mixing market is projected to reach $5 billion by 2025. This growth indicates the importance of selecting the right equipment. Ribbon blenders are popular for powder mixing tasks. They efficiently combine different materials while minimizing segregation. On the contrary, high-shear mixers are preferred for emulsifying and dispersing applications. They ensure uniformity in products like lotions.

However, choosing a mixer requires careful consideration of your needs. The volume of production and the types of materials play significant roles. Oversizing can lead to inefficiencies. Yet, selecting equipment that is too small may compromise quality. Many companies struggle with this balance. Regular assessment of mixer performance is essential for long-term success.

When assessing capacity and size requirements for a chemical mixer machine, several factors come into play. The volume of materials to be mixed is a primary consideration. According to industry reports, the typical mixing volume can vary widely, ranging from a few liters to thousands of liters. It’s crucial to analyze your production goals. If your demand fluctuates, a versatile mixer with adjustable capacity could be beneficial.

Additionally, the physical attributes of your operation space are essential. The machine must fit well in your existing setup. Measure the area not just for the mixer but also for ancillary equipment. Industry standards suggest leaving ample space for maintenance and operation, typically at least 1 meter around the machine. Overcrowding can lead to inefficiencies and potential safety hazards.

Choosing the correct size can impact mix quality. A mixer that is too small will struggle with uniformity. Conversely, an oversized mixer may waste resources. A study indicated that poorly sized mixers could decrease efficiency by up to 20%. Continuously monitor and adjust based on your outcomes. Effective sizing is an ongoing process that requires reflection on production needs and changing constraints.

This bar chart illustrates the capacity requirements for different types of chemical mixers based on their applications. The data represents the average mixing capacities suitable for various industries.

When evaluating mixer performance and efficiency standards, several key factors come into play. The mixing time is crucial. Industry reports indicate that optimal mixing can reduce time by up to 30%. This increases productivity significantly. In many processes, energy consumption is another major point. A mixer designed for high efficiency may use up to 40% less energy compared to standard models. This not only saves money but also reduces environmental impact.

Another important aspect is the mixer’s ability to handle different viscosities. Some reports suggest that mixers can struggle with materials over a certain viscosity, leading to inefficiencies. Operators need to ensure the mixer can adapt. Also, maintenance issues can arise unexpectedly. A study revealed that over 20% of downtime in production is attributed to mixer failures. Regular maintenance checks can mitigate this, but companies often overlook this necessity.

Finally, consider the scalability of the mixer. A well-performing mixer in a small batch process might not yield the same results in large-scale production. Some designs do not scale well. This mismatch can lead to wasted resources and inefficiencies. Companies should analyze specific needs before finalizing a purchase. Evaluating these performance metrics carefully can lead to better operational decisions.

When selecting a chemical mixer machine, maintenance and support options are crucial. A study from the Global Mixers Market Report shows that improper maintenance can lead to 30% more downtime. Regular checks and proper upkeep are essential. Many operators overlook this aspect, assuming mixers require little attention. However, machinery can fail without routine inspection.

Understanding the support options is equally important. Some vendors offer on-site assistance while others focus on remote support. According to research, 40% of companies prefer immediate onsite assistance during failures. This highlights the need for timely communication and reliable service channels. Yet, some mixers come with limited manuals, causing confusion when issues arise. Users often struggle to interpret guidelines that could prevent costly repairs.

Investing in a reliable maintenance plan can save money in the long run. A report suggests that organizations implementing robust maintenance strategies see a 25% increase in efficiency. However, many still undervalue this aspect and face unexpected challenges. Awareness of maintenance needs can enhance operational performance and longevity of the mixers. Ignoring these elements could result in wasted resources and missed production opportunities.