Choosing the right bag on valve filling machine is crucial for production efficiency. Many factors influence this decision. The right bag can enhance product preservation and ensure user convenience.

Quality is a primary concern. A well-designed bag can prevent leaks and maintain product integrity. Consider the material. It should fit with your product’s needs. Different products may require different bag materials, such as plastic or aluminum.

Cost is another important factor. Sometimes, cheaper options may lead to more significant issues later. Think about the long-term investment. The right machine can save money and improve quality. Evaluate your options carefully. This choice impacts your overall success.

When selecting bags for valve filling machines, several key considerations come into play. The material of the bag is critical. Polyethylene and polypropylene are popular choices, as they provide strength and flexibility. Industry reports indicate that proper material selection can lead to a 30% reduction in product waste. This highlights the importance of choosing the right bag to maintain efficiency.

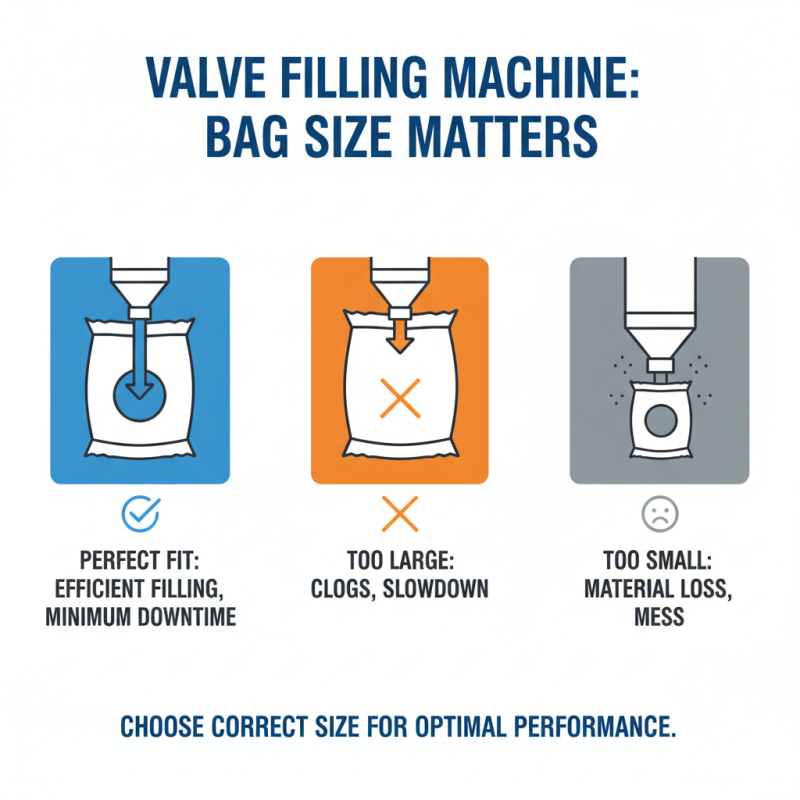

Size and dimensions are another vital consideration. Bags must fit the filling machine precisely. A poorly sized bag can cause jams or spillage, leading to downtime. Studies show that 20% of companies experience operational delays due to improper bag dimensions. It's crucial to measure and verify before making a choice.

Another factor to reflect upon is sealing techniques. The seal quality can directly affect shelf life and product integrity. While heat seals are common, cold seals may offer advantages for delicate products. However, a 2022 report found that 15% of users faced challenges with weaker cold seals. This inconsistency raises questions about the best sealing method. Balancing these factors is essential in optimizing the filling process and ensuring product safety.

Choosing the right bag for valve filling machines is crucial. Various types of bags can impact efficiency and product quality. One popular option is the stand-up pouch. These bags have a flat bottom and can hold their shape, making them ideal for various products. They work well for powders and granules.

Another viable choice is the gusseted bag. These bags can expand when filled, allowing them to hold more volume. This feature is great for bulk products. However, they can sometimes be challenging to seal properly. It’s important to test different sealing techniques to avoid product leakage.

Kraft paper bags are also common for valve filling. They provide excellent durability and are biodegradable. Still, they might not be suitable for all products due to moisture sensitivity. It’s essential to consider the nature of the product when choosing. Balancing material properties with filling requirements is key for optimal performance.

Choosing the right bag for your valve filling machine is critical. Material strength plays a vital role in ensuring durability. Ideal materials include polyester, polyethylene, or nylon. Each has unique properties. For instance, polyester is known for its resistance to wear and tear.

Compatibility with the product being filled is equally important. The bag must withstand various pressures and temperatures. A mismatch can lead to issues. It’s essential to test different materials to assess their performance. Sometimes, even small changes in the material can make a significant difference.

Consider the environment in which the bags will be used. Will they face harsh conditions? This factor can influence your choice. A bag may appear sturdy but fail under certain conditions. Don’t overlook these practical details. Reflecting on past choices can help improve future decisions. Balancing strength and compatibility is not always straightforward. It requires careful consideration and sometimes trial and error.

When selecting bags for a valve filling machine, size is crucial. The bag must fit the filling spout perfectly to avoid spills. A proper fit ensures that the filling process is efficient and minimizes downtime. If the bag is too large, it might cause clogs. A bag that’s too small could lead to material loss.

Take into account the thickness and flexibility of the bag material as well. Thicker bags resist punctures but can be harder to fill. Flexible bags may be easier for filling but can get damaged easily. Testing various sizes can help identify the perfect combination for your application. Adjusting sizes based on your specific needs can save time and resources in the long run.

It's essential to review your filling environment, too. Factors like temperature and material viscosity can affect bag performance. Consider that not every bag works well in every setting. What may be efficient in one scenario could lead to frustrations in another. Flexibility in choosing the right bag can lead to continuous improvement in your filling process. Adaptability is key.

Choosing the right bag for a valve filling machine involves careful consideration of cost and quality. Striking a balance is crucial. Bags that are too cheap might fail during the filling process, leading to waste. Conversely, high-quality bags can significantly increase costs. Finding that middle ground is key.

When selecting bags, consider their materials. Some bags are made from lightweight plastics, while others use more robust options. Lightweight materials might save money. However, they can compromise strength. Ask yourself if the savings are worth the potential risks.

Here are some tips: Evaluate the bag's thickness. Thicker bags generally offer better durability. Assess their barrier properties too. Do they protect against moisture and oxygen? Test samples before making a commitment. Their performance will reveal a lot. Remember, this choice impacts product quality and operational efficiency.