In the world of manufacturing, the "Chemical Mixer Machine" plays a vital role. These machines integrate various materials efficiently, ensuring consistent quality. According to Dr. Lisa Chen, an expert in industrial mixing technologies, “The right mixer can transform production capabilities.” Her insights highlight the importance of understanding these machines.

Chemical Mixer Machines come in different types, from batch mixers to continuous mixers. Each type serves specific purposes. Yet, not every machine is perfect for every application. Exploring the nuances can lead to improved processes. Not all mixers handle materials uniformly, which can affect the final product's quality.

Furthermore, operator training is crucial for efficiency. Without proper knowledge, even the best machines can fall short. The intricacies of mixing technology demand attention and expertise. Each mixer has strengths and weaknesses. Identifying these can lead to better outcomes in production lines. Understanding these facts is essential for anyone involved in this industry.

Chemical mixer machines play a critical role in various industries, including pharmaceuticals, food, and chemicals. These machines blend materials to achieve homogeneity, which is essential for product quality. According to a recent market report, the global chemical mixer market is projected to grow at a CAGR of 4.8% over the next five years. This reflects a rising demand in sectors that require precise mixing processes.

The purpose of chemical mixer machines is to enhance the consistency of products. They are crucial in producing paints, coatings, and adhesives. A well-mixed batch leads to improved performance and customer satisfaction. However, improper use can lead to various issues, including separation and a lack of uniformity in final products.

Understanding optimal mixing time and speed is vital, as too much energy can degrade sensitive materials.

In addition, these machines require regular maintenance to function effectively. Neglecting upkeep can result in downtime, affecting production schedules. It's essential for operators to have training and understanding of the equipment's intricacies.

Data shows that over 20% of operating costs can be attributed to mechanical failures, highlighting the need for diligence in machine care. Balancing efficiency and quality control remains a challenge, but it is necessary for sustainable operations.

Chemical mixer machines play an essential role in various industries. Understanding their types and functions can help you choose the right one for your needs. There are several types of chemical mixers, including batch mixers and continuous mixers. Batch mixers are used for small production runs. They mix materials in fixed quantities. Continuous mixers provide a steady flow of materials. They are suitable for large-scale production.

Another common type is the ribbon mixer. This machine has a helical ribbon that ensures uniform mixing. It is effective for powders and granules. Planetary mixers are also noteworthy. They mix materials by rotating and orbiting simultaneously. This type is ideal for viscous substances.

Tip: Always consider the material characteristics. This affects the choice of mixer type. For highly viscous materials, a planetary mixer may be ideal.

Chemical mixers require regular maintenance. Sometimes, users overlook this, leading to performance issues. You should also ensure the mixer is cleaned properly between uses. This prevents contamination of different batches.

Tip: Keep a maintenance schedule. Regular checks can save time and costs down the line. Don't ignore unusual noises or vibrations. They can be signs of trouble.

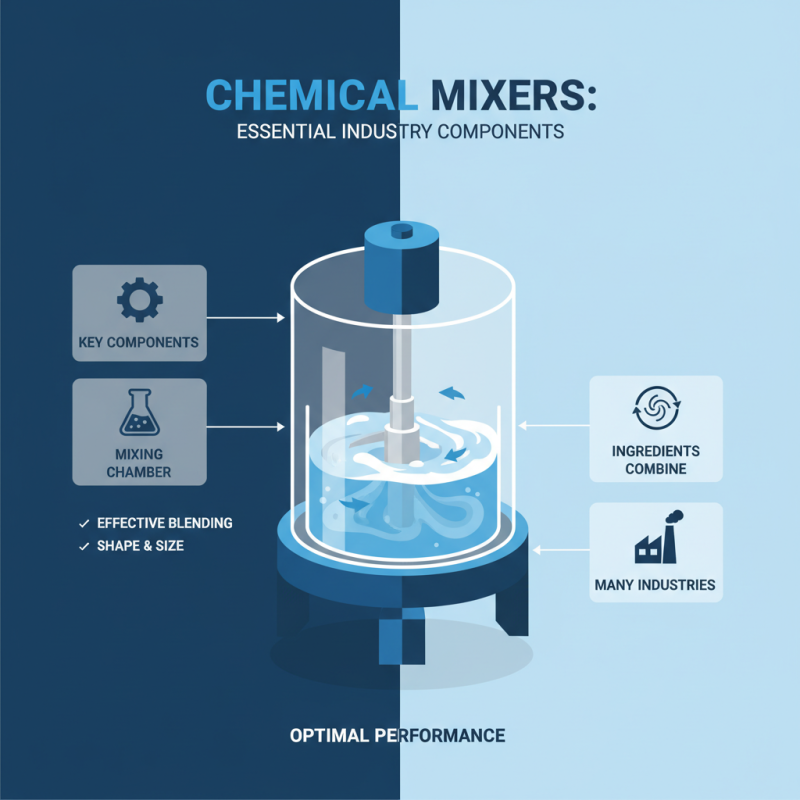

Chemical mixer machines are essential in many industries. Key components of these machines play crucial roles in their performance. The mixing chamber is where ingredients combine. This part should be designed for effective blending. It's important to consider its shape and size.

The motor powers the entire machine. A reliable motor ensures consistent mixing. If the motor fails, production halts. Proper maintenance is necessary. Regular checks can prevent breakdowns. Replace worn parts to extend the machine's life.

Mixing blades are critical too. Their design impacts the mixing quality. Different blade shapes achieve varying results. Experimenting with blade styles can lead to better outcomes. Sometimes, you may find the wrong blades are used, affecting the end product.

Tip: Always keep a maintenance log. Tracking repairs and replacements helps in planning. Another tip is to test different mixing speeds. This can dramatically change the efficiency of your process. Pay attention to how changes affect your final product.

When selecting a chemical mixer machine, several factors are crucial for optimal performance. Capacity is one of the key considerations. You need to determine the volume of material to be mixed. This will impact your choice of mixer size. A mixer that is too small will lead to inefficient mixing and potential damage.

Another important factor is the type of mixing process required. Different processes call for specific machines. For example, high viscosity materials require mixers with more torque. Consider the machine's design as well. Look for features like adjustable speeds and specialized blades. These enhance the mixing quality but can also complicate operation.

Material compatibility also plays a vital role. Ensure the mixer can handle the chemicals you plan to use. Some materials can be corrosive, leading to wear and tear. Maintenance needs should not be overlooked. A machine that is hard to clean may lead to contamination. Think about the long-term implications of your choice. Considering all these aspects is essential to avoid issues later on.

| Fact No. | Description | Considerations |

|---|---|---|

| 1 | Chemical mixers are essential for uniformity in mixing processes. | Assess the required mix quality. |

| 2 | They come in various types such as batch and continuous mixers. | Choose based on production requirements. |

| 3 | Materials of construction affect durability and chemical compatibility. | Evaluate the chemical nature of materials being mixed. |

| 4 | Efficiency can vary significantly based on design. | Consider the design specific to your application. |

| 5 | The power and speed of the mixer influence mixing time. | Measure your mixing time needs accurately. |

| 6 | Safety features are crucial in handling hazardous materials. | Check for compliance with safety regulations. |

| 7 | Maintenance requirements vary by mixer type. | Plan for regular maintenance check-ups. |

| 8 | Mixing volume capacity can impact production scales. | Ensure it matches your production volume. |

| 9 | Operational costs can vary based on energy consumption. | Calculate lifecycle costs before purchasing. |

| 10 | Advanced technology in mixers can enhance precision. | Research the latest innovations in mixer technology. |

Proper maintenance of chemical mixer machines is crucial for their longevity and efficiency. Regular inspections help identify wear and tear early. Check seals and gaskets for leaks. These small issues can lead to larger problems if ignored. Keeping your machine clean is equally important. Residue buildup can affect performance and safety.

Lubrication is vital. Use the right type of lubricant on moving parts. An inadequate amount can cause friction and overheating. It’s wise to maintain a schedule for lubrication. Training staff on proper operation can also reduce mistakes. Many issues arise from improper use, which can be preventable.

Finally, keep an eye on performance trends. Sudden changes in output may signal underlying issues. Consistent monitoring allows for timely repairs. While it's easy to overlook these tasks, neglecting them can lead to costly downtime. Investing time in maintenance ensures optimal functionality and saves money in the long run.