In the rapidly evolving landscape of industrial processing, the demand for advanced technologies that enhance product quality and efficiency has never been greater. High Shear Homogenizers have emerged as pivotal tools across various sectors, including food and beverage, pharmaceuticals, and cosmetics, thanks to their remarkable ability to create uniform particle sizes and stable emulsions. According to a recent market research report by MarketsandMarkets, the global high shear mixer market is projected to reach USD 1.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6% from 2020. This growth is driven by the increasing need for improved textures and efficacy in products, where High Shear Homogenizers play a critical role in ensuring consistency and quality. As industries continue to innovate, uncovering the unique applications of High Shear Homogenizers will be crucial for meeting the sophisticated demands of modern consumers.

High shear homogenizers have revolutionized multiple industries through their innovative technologies, providing unparalleled efficiency in material processing. According to a recent report from MarketsandMarkets, the global homogenizers market is projected to reach $1.9 billion by 2025, growing at a CAGR of 5.6%. This growth underscores the increasing demand for high shear homogenizers in sectors such as pharmaceuticals, food and beverage, and cosmetics, where achieving uniformity and stability in formulations is critical.

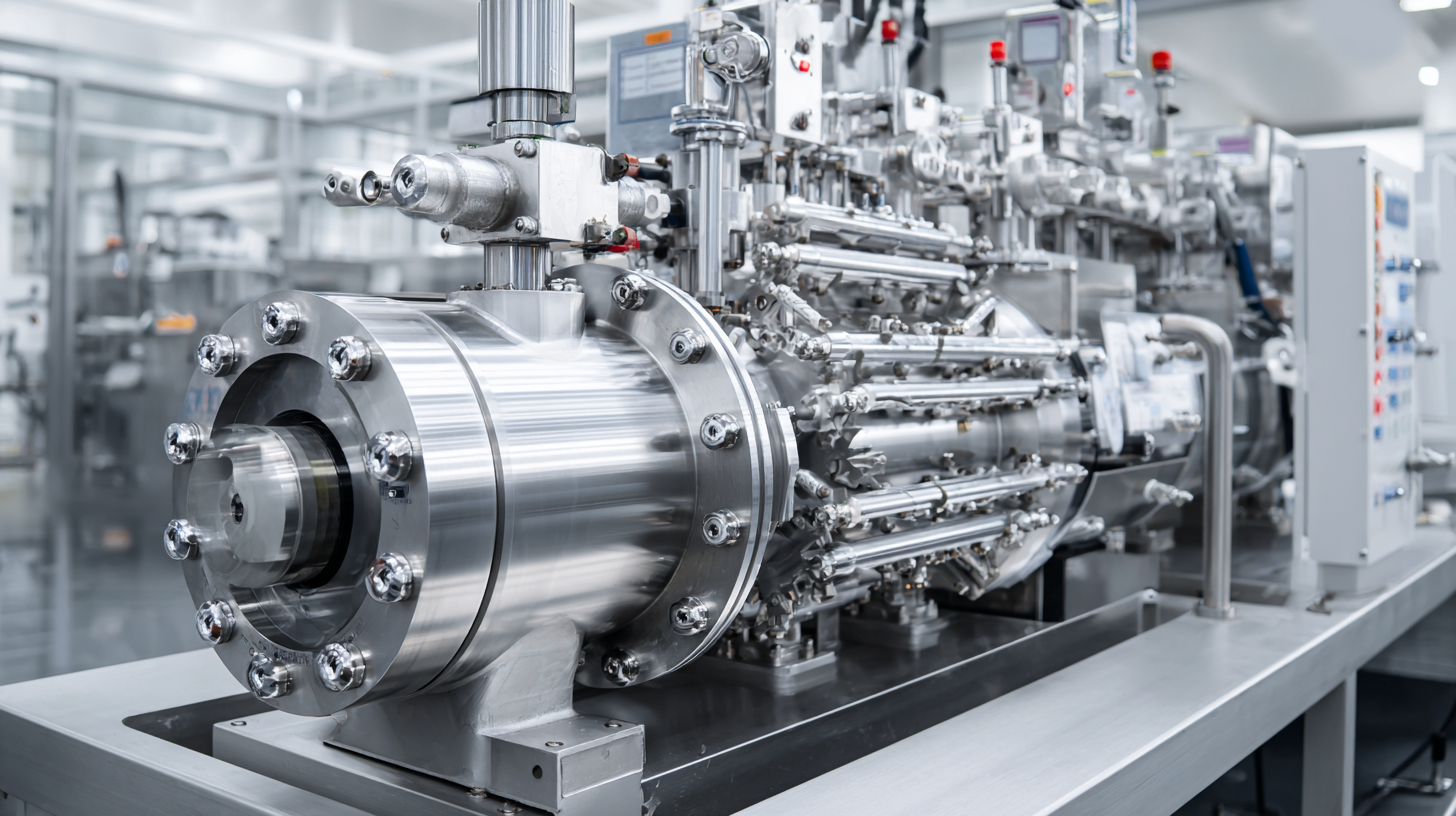

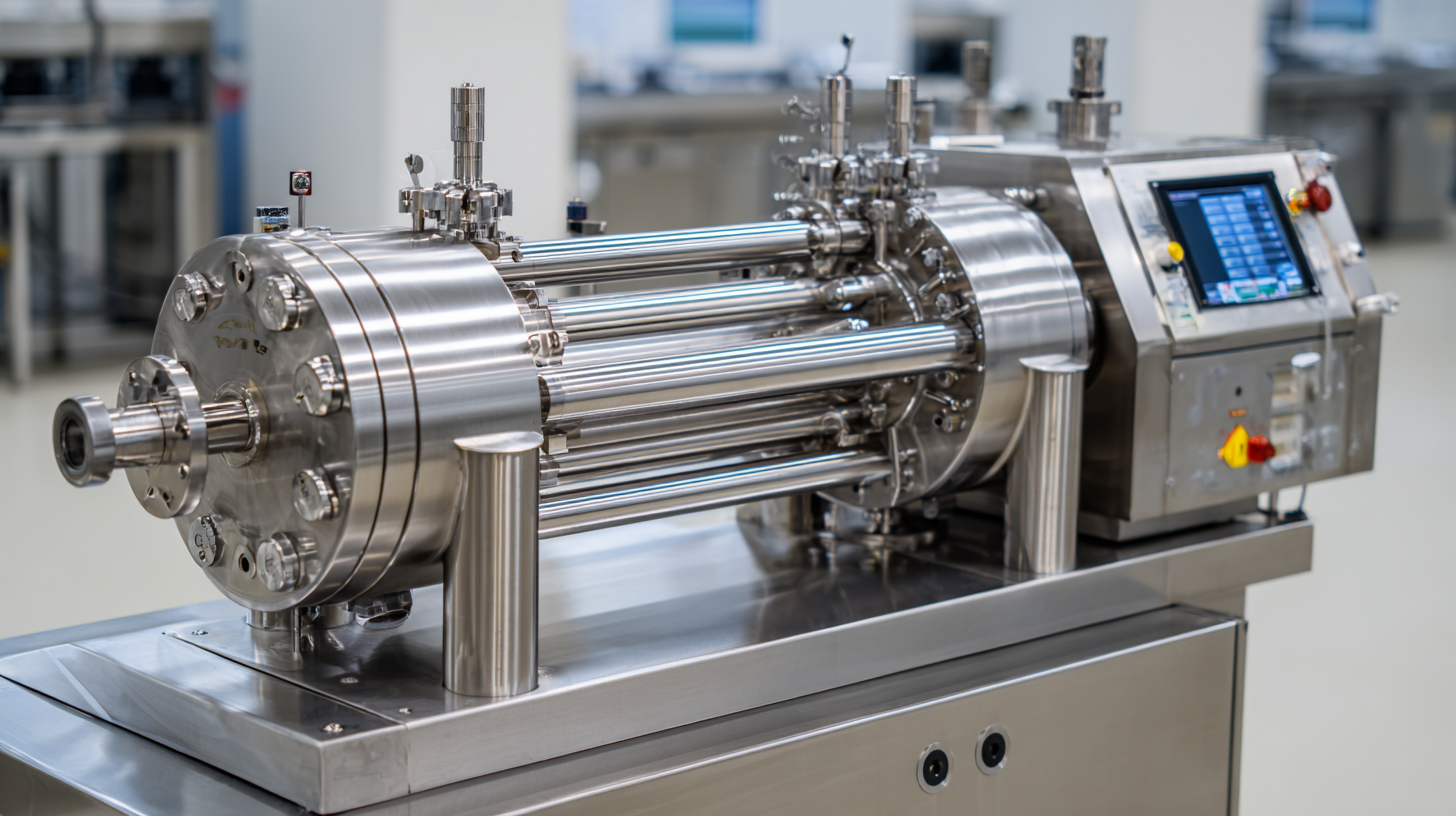

One of the key innovations driving this efficiency is the introduction of advanced rotor-stator designs, which enhance the shear force applied to materials. These designs, combined with automated control systems, allow for precise adjustments in processing conditions, resulting in improved product quality and production speed. A study published by ResearchAndMarkets highlights that in the pharmaceuticals industry, high shear homogenizers are pivotal in the manufacturing of potent drug formulations, particularly in creating nano-emulsions that increase bioavailability. Such advancements not only elevate the standard of product quality but also optimize resource utilization, making high shear homogenizers an indispensable tool in modern production lines.

One of the key innovations driving this efficiency is the introduction of advanced rotor-stator designs, which enhance the shear force applied to materials. These designs, combined with automated control systems, allow for precise adjustments in processing conditions, resulting in improved product quality and production speed. A study published by ResearchAndMarkets highlights that in the pharmaceuticals industry, high shear homogenizers are pivotal in the manufacturing of potent drug formulations, particularly in creating nano-emulsions that increase bioavailability. Such advancements not only elevate the standard of product quality but also optimize resource utilization, making high shear homogenizers an indispensable tool in modern production lines.

High shear homogenizers play a pivotal role in the food and beverage industry, particularly in enhancing the efficiency of emulsification processes. Recent insights into thermal processing and emulsification methods highlight their impact on flavor release and emulsion stability, specifically in spice oleoresin blending. Studies reveal that optimal heat treatments can significantly improve the pungency and aroma profiles of spice blends, leading to more robust flavor experiences for consumers.

Data indicates that utilizing high shear homogenizers can lead to improved emulsion stability by maintaining a uniform particle size distribution, which is crucial for preventing phase separation. A report from the Food Processing Industry suggests that products processed with high shear methods exhibit a 30% longer shelf life compared to those that do not use such techniques. Furthermore, this method enhances flavor release by creating more efficient emulsions, ensuring that consumers experience the intended taste and aroma in every bite or sip. The integration of high shear homogenization in food formulations not only elevates product quality but also aligns with consumer demand for fresh and flavorful experiences.

| Application | Industry | Process Type | Efficiency Improvement (%) | Cost Reduction (%) |

|---|---|---|---|---|

| Emulsification | Food & Beverage | Liquid Mixing | 30% | 15% |

| Particle Size Reduction | Dairy | Homogenization | 25% | 10% |

| Stabilization | Beverage | Mixing & Blending | 20% | 12% |

| Creaming Prevention | Sauce | Emulsification | 15% | 8% |

| Flavor Enhancements | Snack Foods | Flavoring | 18% | 9% |

High shear homogenizers have revolutionized the pharmaceutical industry, particularly in enhancing the bioavailability of drug formulations. In an era where patient compliance and treatment efficacy are paramount, these devices play a vital role in the production of uniform and stable pharmaceutical products. By applying mechanical forces to mixtures, high shear homogenizers effectively reduce particle size and improve the dispersion of active pharmaceutical ingredients (APIs) within a medium, promoting better absorption in the body.

One of the unique applications of these homogenizers is in the creation of emulsions and suspensions that are essential for delivering lipophilic drugs. Traditional methods often fall short in achieving the necessary particle size reduction; however, high shear homogenizers facilitate this process by generating high shear forces, which ensure that the particles remain suspended and evenly distributed. This results in formulations that not only enhance the solubility of drugs but also optimize their therapeutic efficacy. As the pharmaceutical industry continues to innovate, high shear homogenizers will undoubtedly remain a cornerstone technology in the development of advanced drug formulations that meet contemporary health care demands.

High shear homogenizers are revolutionizing the cosmetic manufacturing industry by fostering sustainable practices that significantly reduce waste. Recent studies indicate that the global nanocellulose market is projected to reach $1.5 billion by 2027, driven by advancements in material technology and eco-friendly formulations. These innovative machines not only enhance product quality through improved emulsification but also minimize the use of raw materials, resulting in less waste generation and a reduced environmental footprint.

Moreover, process intensification (PI) techniques are gaining traction in various sectors, particularly food processing. By optimizing the production processes, PI contributes to increased productivity and resource efficiency, allowing for a more sustainable approach to manufacturing. Implementing high shear homogenization alongside PI can lead to substantial cost savings and a more streamlined workflow.

**Tip:** To further enhance sustainability in cosmetic production, consider integrating high shear homogenizers with renewable and biodegradable ingredients. This combination not only heightens performance but also aligns with consumer demand for greener products. Additionally, routine maintenance of your high shear homogenizers ensures optimal efficiency and longevity, thus minimizing operational waste.

The market for high shear homogenizers is seeing significant projected growth across various sectors as industries increasingly recognize their versatility and efficiency. These advanced machines are pivotal in applications ranging from pharmaceuticals to food processing, enabling the precise mixing, emulsification, and homogenization of products. In the pharmaceutical sector, for instance, the ability to produce stable emulsions ensures the effectiveness of drug formulations, which is essential in developing new therapies. The continuous advancements in technology further amplify the demand for high shear homogenizers, creating opportunities for innovative solutions that meet evolving industry standards.

In the food and beverage industry, the trend towards clean-label products has spurred the need for high-quality emulsification and mixing processes. High shear homogenizers provide a means to create smooth textures and uniform distributions of ingredients without compromising product integrity. Coupled with the growing consumer preference for natural and organic food options, manufacturers are increasingly turning to these machines to enhance product quality while maintaining compliance with health regulations. As these trends continue to flourish, the applications of high shear homogenizers are expected to expand, solidifying their role as essential tools in the manufacturing processes across a wide array of industries.