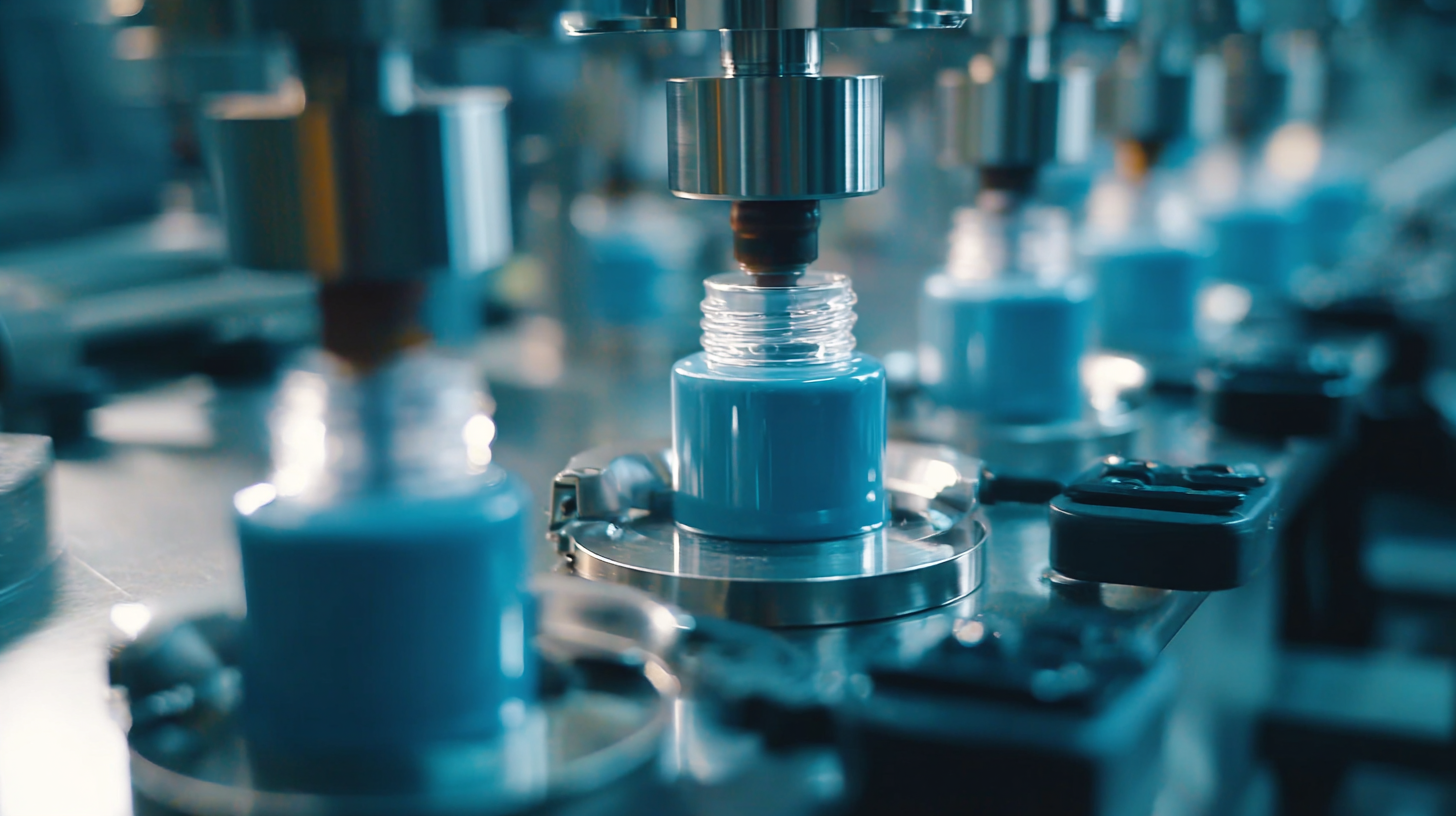

As the global market for aerosol products continues to expand, driven by increasing consumer demand in personal care, household goods, and industrial applications, the role of advanced Aerosol Filling Machines has become crucial. According to a recent industry report, the aerosol packaging market is projected to reach approximately $97 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 5.8%. This growth underscores the necessity for manufacturers to invest in high-quality filling machines that enhance efficiency, precision, and product integrity.

The best Aerosol Filling Machines not only improve production capabilities but also meet evolving regulatory standards and customer expectations. In this blog, we will explore the unique features and applications of these machines, offering insights into their design, technology, and impact on various industries to benefit global buyers seeking optimal solutions in their manufacturing processes.

When it comes to aerosol filling machines, adherence to key industry standards is crucial for manufacturers aiming to ensure product safety and efficiency. The global aerosol filling machine market is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by the increasing demand for aerosol-based products across multiple sectors. According to a recent report by Fortune Business Insights, quality compliance standards such as ISO 9001:2015 have become essential benchmarks for manufacturers. These standards facilitate the implementation of quality management systems that enhance operational efficiency, reduce waste, and ensure customer satisfaction.

Moreover, regulatory frameworks like the Occupational Safety and Health Administration (OSHA) standards and the Environmental Protection Agency (EPA) regulations play vital roles in shaping the operational landscape. As aerosol products often contain volatile organic compounds (VOCs), the EPA mandates strict guidelines to minimize environmental impact. Industry experts note that compliance with these guidelines not only helps in avoiding hefty fines but also builds brand reputation, crucial for global buyers seeking reliable partners in the aerosol filling ecosystem. Emphasizing these standards not only serves compliance needs but also aligns with the growing consumer consciousness toward sustainability and safety in product offerings.

The aerosol filling industry has undergone significant transformations driven by innovative technologies. Enhanced automation and precision engineering have made filling processes more efficient than ever. According to a recent market report, the global aerosol filling machines market is projected to grow at a CAGR of 5.2% over the next five years, indicating a rising demand for efficient and reliable filling solutions. Technologies such as smart sensors, real-time monitoring, and advanced robotics are at the forefront, ensuring that products not only meet stringent quality standards but also cater to the increasing consumer demand for eco-friendly packaging.

Tips for buyers looking to invest in aerosol filling machines include focusing on the machine's compatibility with various product formats and sizes. This adaptability can significantly impact production efficiency and versatility. Additionally, consider the energy consumption of the machinery, as advancements in energy-efficient technologies can lead to substantial cost savings over time. Furthermore, look for machines equipped with IoT capabilities, as they allow for remote operation and maintenance, ultimately reducing downtime and enhancing overall productivity in the manufacturing process.

In the world of aerosol filling machines, understanding the unique features and applications available on the global market is crucial for buyers looking to enhance their production capabilities. The comparative analysis of top aerosol filling machines reveals a growing trend in various industries, including pharmaceuticals, which is experiencing significant market growth. The global pharmaceutical packaging equipment market is expected to reach $10.5 billion by 2025, growing at a robust 6.3% CAGR. This increase highlights the need for advanced filling machines that ensure efficiency, precision, and compliance with stringent regulatory standards.

In the world of aerosol filling machines, understanding the unique features and applications available on the global market is crucial for buyers looking to enhance their production capabilities. The comparative analysis of top aerosol filling machines reveals a growing trend in various industries, including pharmaceuticals, which is experiencing significant market growth. The global pharmaceutical packaging equipment market is expected to reach $10.5 billion by 2025, growing at a robust 6.3% CAGR. This increase highlights the need for advanced filling machines that ensure efficiency, precision, and compliance with stringent regulatory standards.

In addition to pharmaceuticals, the spray dried food market is projected to experience significant growth from 2025 to 2035, further pushing the demand for innovative aerosol filling solutions. Choosing the right filling machine can dramatically impact production efficiency and product quality.

Tips: When selecting an aerosol filling machine, consider the machine's compatibility with various product viscosities and container types. Additionally, look for equipment that offers easy integration with existing production lines to maximize your investment. Regular maintenance and updates can also ensure long-term efficiency and compliance with industry standards.

In the aerosol production industry, compliance with safety standards is not just a regulatory requirement but a critical factor that influences operational efficiency and product quality. According to the "Global Aerosol Spray Market Report 2023," over 70% of companies identified compliance with safety regulations as a key challenge in enhancing their production processes. With strict guidelines set by organizations such as OSHA and EPA in the United States, manufacturers must ensure that their aerosol filling machines operate within defined limits for both environmental safety and worker protection.

Understanding these compliance standards equips industry players to make informed decisions when selecting aerosol filling machines. The European Aerosol Federation (FEA) emphasizes that utilizing machinery that meets CE marking standards can significantly reduce the risk of product recalls and safety incidents, which affect an estimated 15% of aerosol products annually. Moreover, adherence to these standards can open new markets, as many international buyers prioritize partnering with manufacturers that prioritize compliance, thereby ensuring consistent quality and safety in their product offerings.

The aerosol filling industry is undergoing significant transformations as technology advances and market demand evolves. One of the most notable trends is the increase in automation within filling processes. Automated aerosol filling machines not only enhance efficiency but also minimize human error, ensuring greater consistency in product quality. As manufacturers strive for higher output rates to meet global demand, the integration of Artificial Intelligence and machine learning into these systems is expected to rise, allowing for real-time monitoring and adjustments during production.

Sustainability is another key factor influencing future trends in aerosol filling technology. With growing concerns over environmental impact, manufacturers are prioritizing eco-friendly practices and materials. Innovations such as recyclable aerosol containers and using less propellant in formulations are gaining traction. The market demand for sustainable products is pushing companies to invest in research and development to create greener alternative solutions, catering to environmentally conscious consumers. As a result, the future of aerosol filling technology not only promises increased efficiency but also a commitment to sustainable practices that resonate with modern buyers.