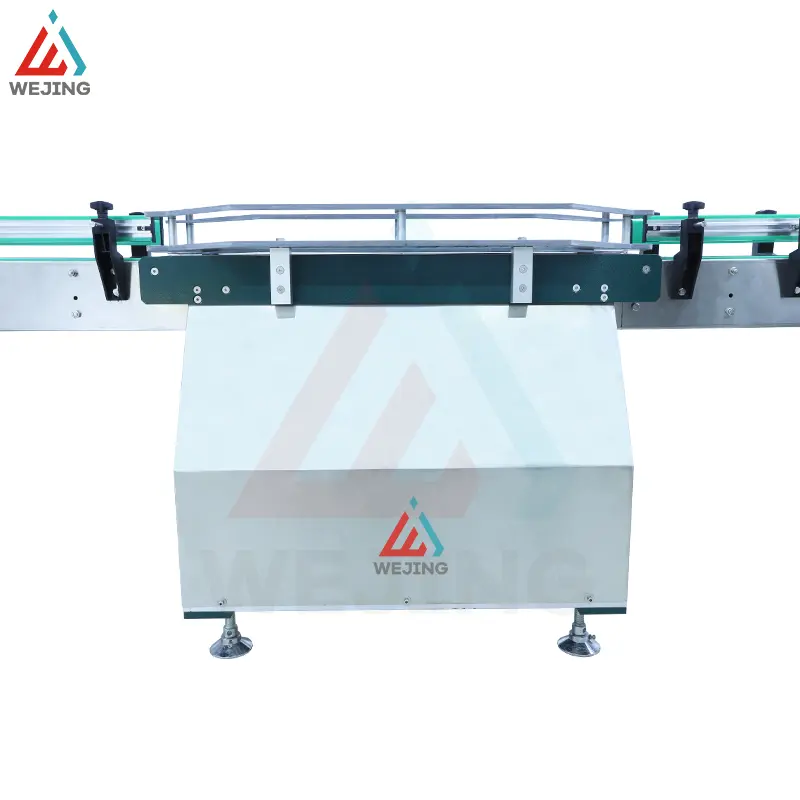

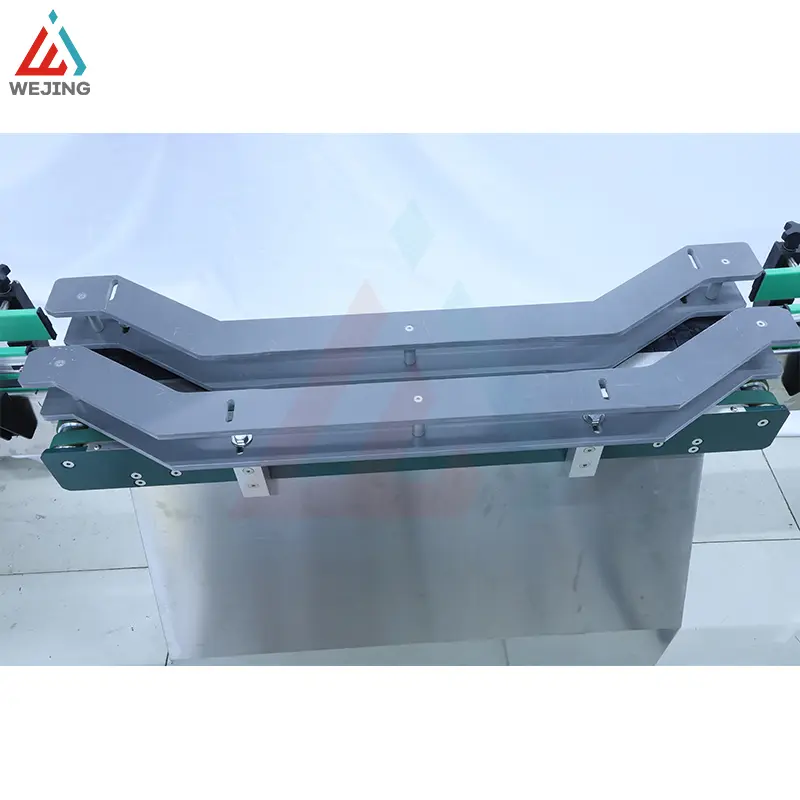

Bov Aerosol Inkjet Conveyor Belt

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

>120 bottles /min |

|

Thickness |

1000x360x850 mm aluminum profile frameside plate 10mm thick iron plate plasticsprayig treatment |

|

Power |

0.18kW/380VAC |

|

Applicable aerosolcan diameter |

35-70mm |

|

Applicable aerosol can height |

80-300 mm |

|

Coding width |

15mm |

|

Size |

1000*360*850mm |

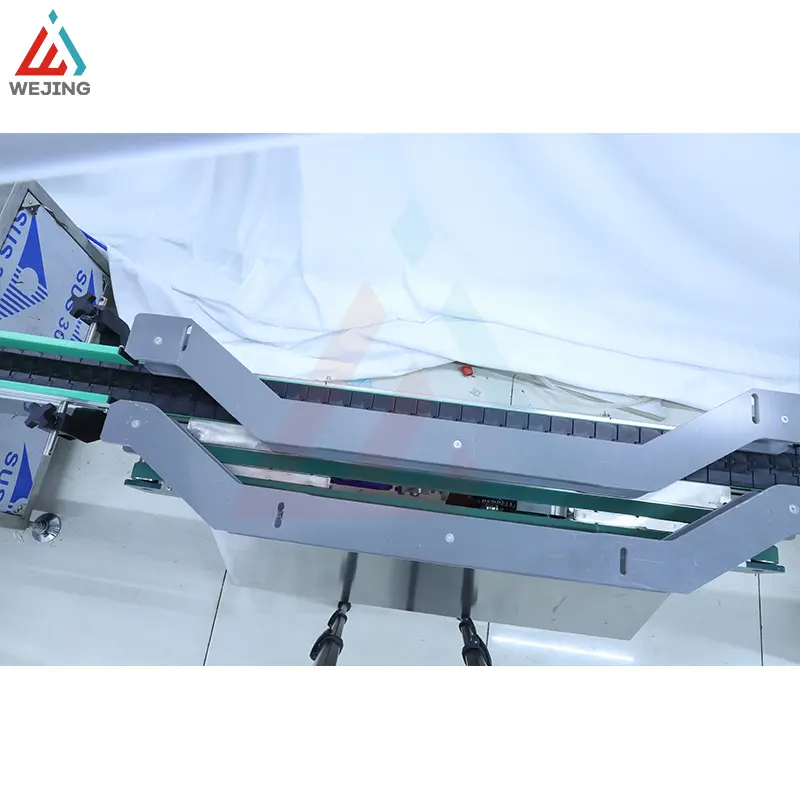

1. Improve productivity: The conveyor belt we designed for inkjet printing accelerates the aerosol filling process, shortens production time, and increases output rate, thereby improving overall operational efficiency

2. Accurate printing accuracy: By ensuring uniform and detailed inkjet application on each aerosol can, our conveyor ensures clear labels, supports product identification and effective tracking.

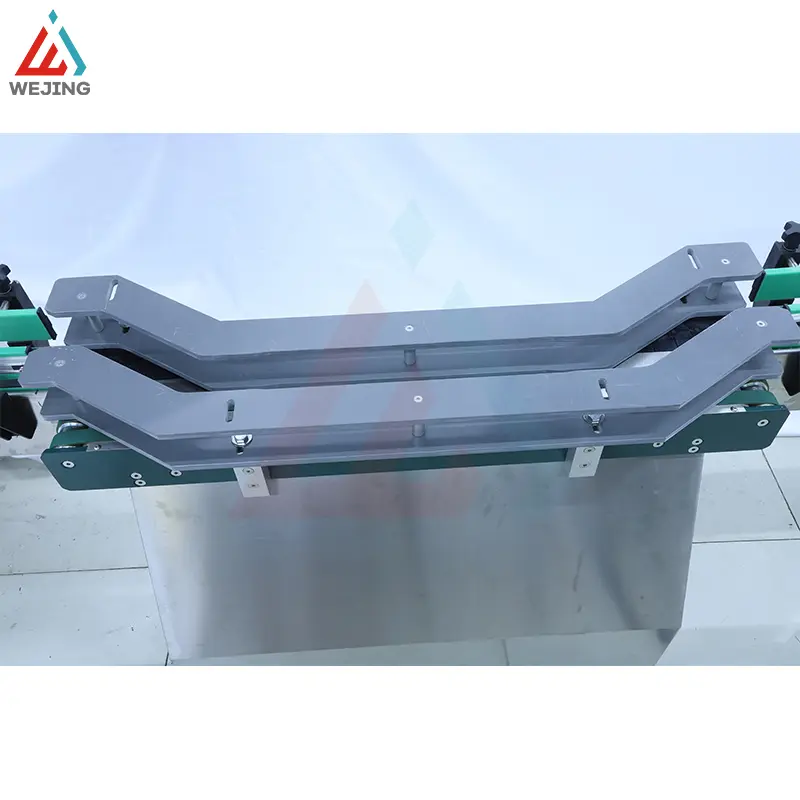

3. Strong mobility and adaptability: Considering portability, our conveyor belts can be easily repositioned and configured to adapt to various manufacturing configurations, providing the necessary flexibility for multifunctional industrial environments.

2. Accurate printing accuracy: By ensuring uniform and detailed inkjet application on each aerosol can, our conveyor ensures clear labels, supports product identification and effective tracking.

3. Strong mobility and adaptability: Considering portability, our conveyor belts can be easily repositioned and configured to adapt to various manufacturing configurations, providing the necessary flexibility for multifunctional industrial environments.

4. Space efficient design: With its compact footprint, our conveyor can be easily integrated into current production layouts, optimizing space utilization and minimizing interference.

5. Consistent and reliable operation: Made of high-quality materials and utilizing the most advanced technology, our inkjet conveyor belts are synonymous with reliability and sustained performance, reducing idle time and ensuring long-lasting productivity.

5. Consistent and reliable operation: Made of high-quality materials and utilizing the most advanced technology, our inkjet conveyor belts are synonymous with reliability and sustained performance, reducing idle time and ensuring long-lasting productivity.

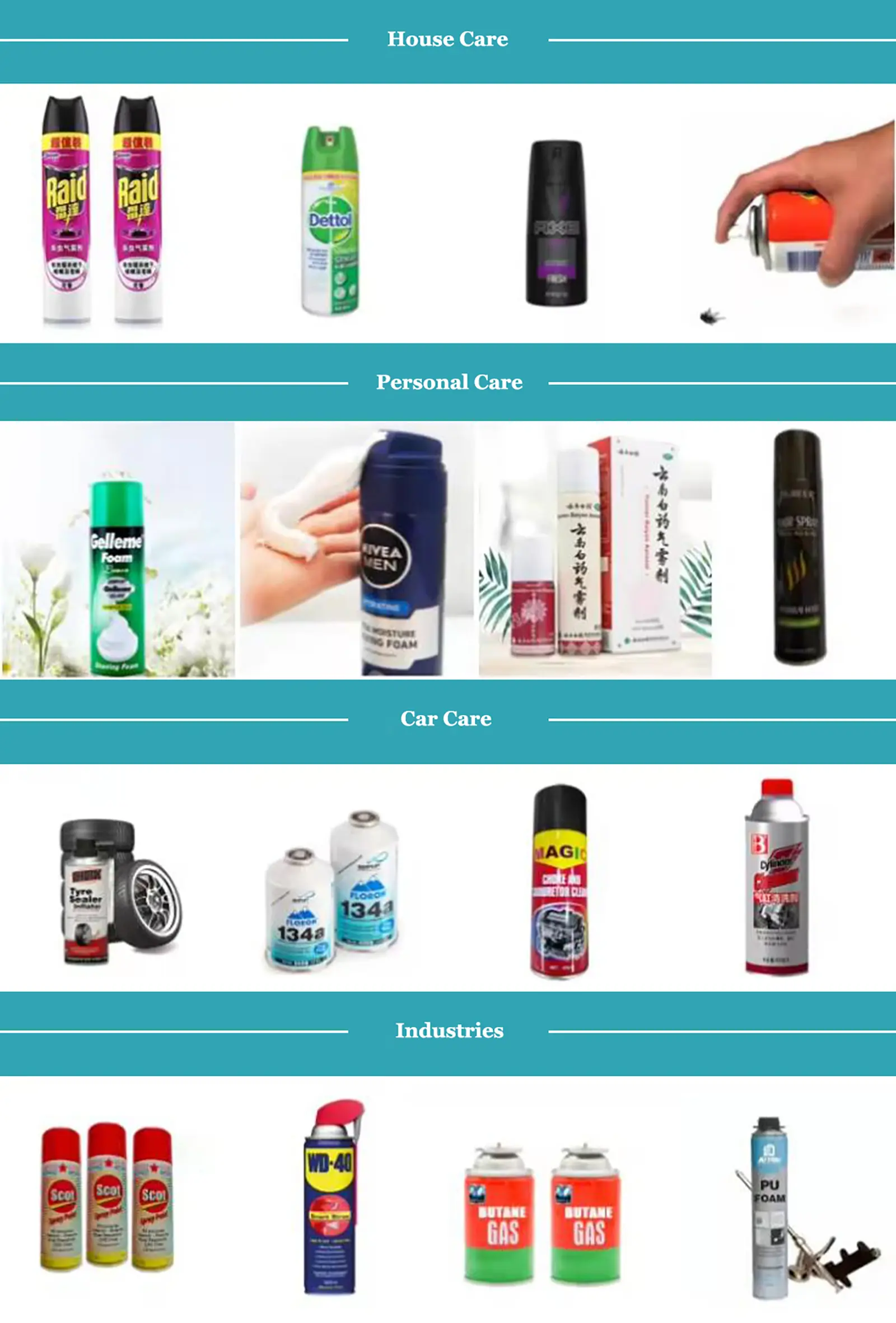

PRODUCT Applications

Suitable for various aerosol can products

Operation Guide

1. Follow the manufacturer's installation instructions and safety protocols, secure the inkjet conveyor belt and synchronize it with the aerosol filling machinery.

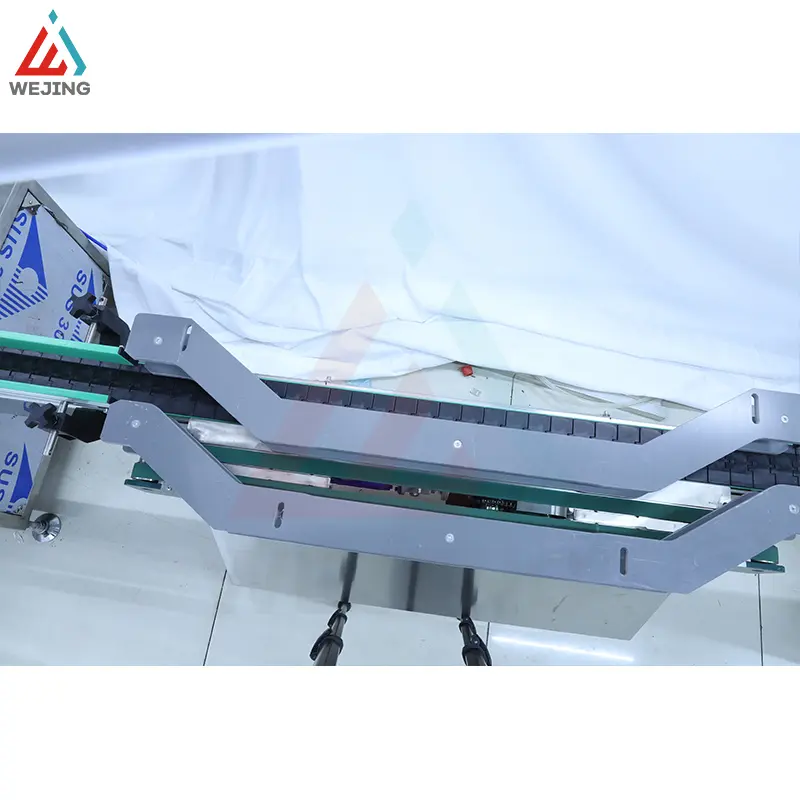

2. Adjust the conveyor speed to synchronize with the production flow requirements, ensuring smooth operation of aerosol containers and achieving optimal inkjet applications.

3. Configure inkjet printer settings according to printing standards, including font size, content composition, and position, to ensure clear and easy to read printing on aerosol bottles.

4. Arrange the aerosol bottles on the conveyor with uniform spacing and correct direction for efficient printing.

5. Maintain vigilance towards inkjet printing operations, regularly check print clarity and alignment, and make necessary modifications to improve printing results, ensuring the entire process is efficient and accurate.

2. Adjust the conveyor speed to synchronize with the production flow requirements, ensuring smooth operation of aerosol containers and achieving optimal inkjet applications.

3. Configure inkjet printer settings according to printing standards, including font size, content composition, and position, to ensure clear and easy to read printing on aerosol bottles.

4. Arrange the aerosol bottles on the conveyor with uniform spacing and correct direction for efficient printing.

5. Maintain vigilance towards inkjet printing operations, regularly check print clarity and alignment, and make necessary modifications to improve printing results, ensuring the entire process is efficient and accurate.