BOV Aerosol Liquid Forced Filling Machine

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Filling capacity |

20-200ml |

|

|

Filling speed |

200-300cans/ hour, depending on filing volume |

|

|

Applicable can |

height |

70-330mm, customization available |

|

diameter |

35-70mm |

|

|

Compressed air Working pressure |

0.7MPa |

|

|

Max. air consumption |

0.2m³/min |

|

Automatic Bag On Valve Aerosol Filling MachineWorking Process

1. Secure the measuring cup onto the spray valve.

2. Pour the prepared components in.

3. Push the measuring cup into the inflation station.

4. Turn on the switch of the pneumatic valve.

5. Fasten the spray tank in place.

2. Pour the prepared components in.

3. Push the measuring cup into the inflation station.

4. Turn on the switch of the pneumatic valve.

5. Fasten the spray tank in place.

Product Advantages

1. Flexible operation: It can adapt to small batch production and multi variety filling, and operators can flexibly adjust parameters.

2. High cost-effectiveness: The price is relatively low, reducing equipment investment costs, and maintenance is simple.

3. Precise filling: Accurately control the filling volume to ensure product quality consistency and adapt to liquids of different viscosities.

4. Strong reliability: simple structure, stable and reliable operation, low probability of failure, and improved production efficiency.

2. High cost-effectiveness: The price is relatively low, reducing equipment investment costs, and maintenance is simple.

3. Precise filling: Accurately control the filling volume to ensure product quality consistency and adapt to liquids of different viscosities.

4. Strong reliability: simple structure, stable and reliable operation, low probability of failure, and improved production efficiency.

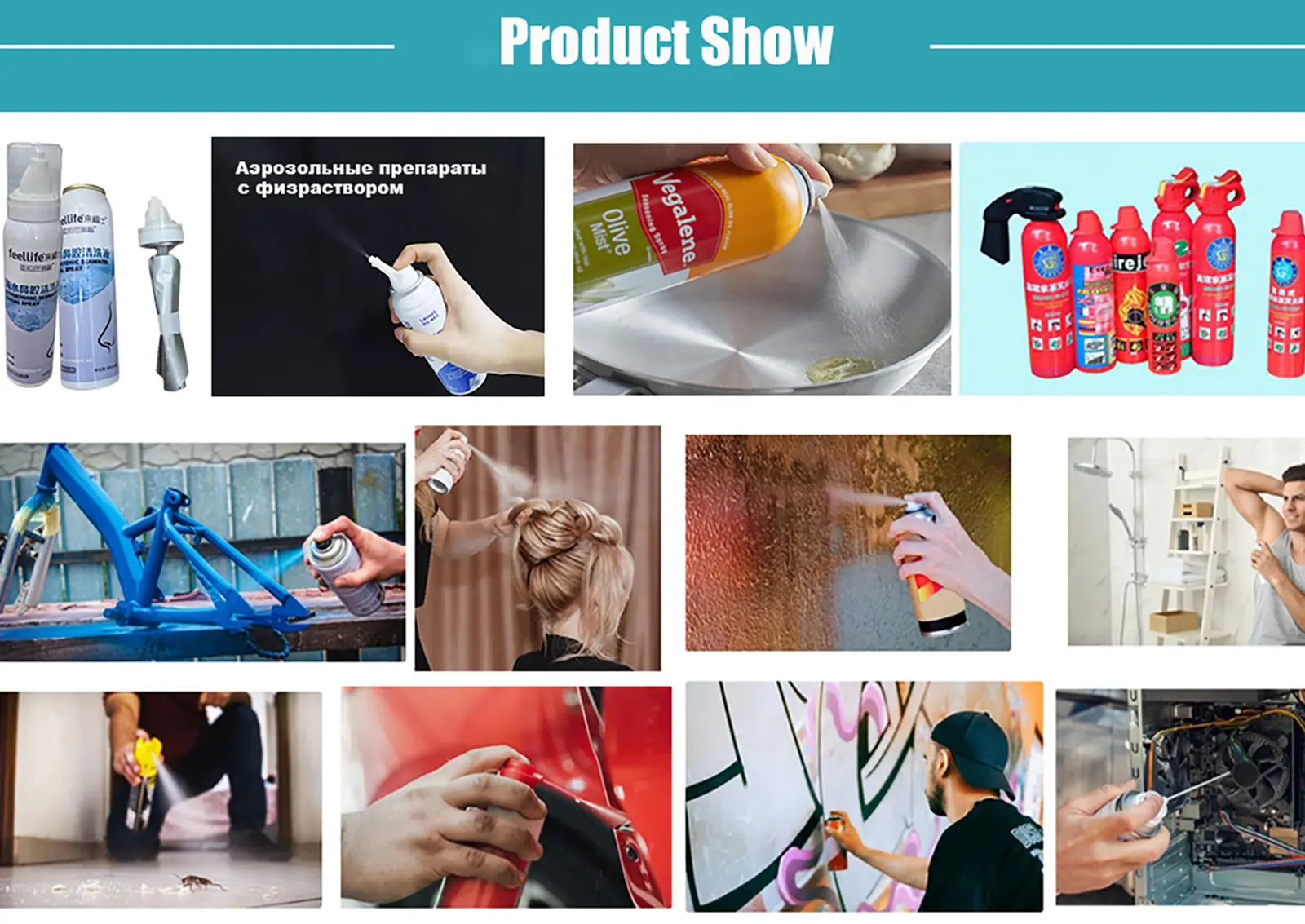

PRODUCT Applications

1. Personal care products encompass body fragrances, insect repellents, sunscreen, hair removal agents and more. These items are dedicated to taking care of your personal hygiene and appearance.

2. Household products include furniture polishing wax, household cleaner, air freshener, pet spray, plant spray, household fire extinguisher, etc. They play a vital role in maintaining a clean, comfortable, and safe household environment.

3. Sanitary products consist of toothpaste, cleaning agents, etc. Their main purpose is to keep our living environment and personal hygiene in good condition.

4. Food involves cream toppers, concentrated drinks, cooking seasonings, juices, sauces, etc. They are designed to meet our taste preferences and nutritional requirements.

5. Industrial supplies like sealing agents, grease and lubricants, industrial oils, etc. are essential for the normal operation of industrial production.

6. Automotive supplies such as adhesives, sealants, polishes, combustion injector cleaning agents, barrier creams, paints, etc. are crucial for the maintenance and performance improvement of vehicles.

7. Drugs including external analgesics, estrogen gel, sterile physiological saline for nasal irrigation, etc. are formulated to treat certain medical conditions and relieve symptoms.

2. Household products include furniture polishing wax, household cleaner, air freshener, pet spray, plant spray, household fire extinguisher, etc. They play a vital role in maintaining a clean, comfortable, and safe household environment.

3. Sanitary products consist of toothpaste, cleaning agents, etc. Their main purpose is to keep our living environment and personal hygiene in good condition.

4. Food involves cream toppers, concentrated drinks, cooking seasonings, juices, sauces, etc. They are designed to meet our taste preferences and nutritional requirements.

5. Industrial supplies like sealing agents, grease and lubricants, industrial oils, etc. are essential for the normal operation of industrial production.

6. Automotive supplies such as adhesives, sealants, polishes, combustion injector cleaning agents, barrier creams, paints, etc. are crucial for the maintenance and performance improvement of vehicles.

7. Drugs including external analgesics, estrogen gel, sterile physiological saline for nasal irrigation, etc. are formulated to treat certain medical conditions and relieve symptoms.