Card Furnace Gas Tank Filling Machine

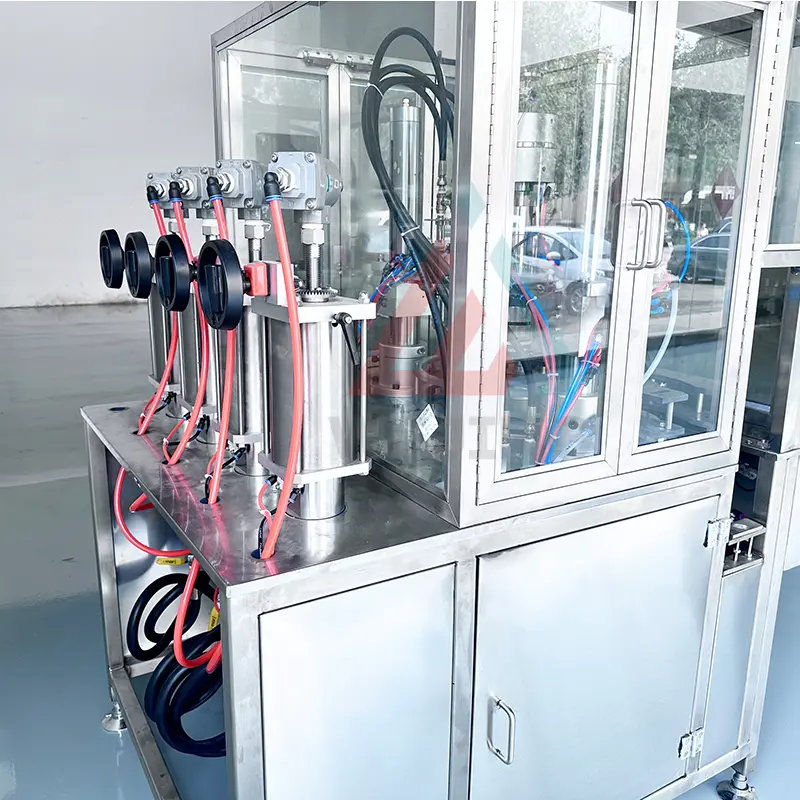

Exactitude in Gas Filling

Adaptability to Gas Types

Reinforced Safety Elements

Streamlined Workflow Incorporation

Hassle-free Operation and Upkeep

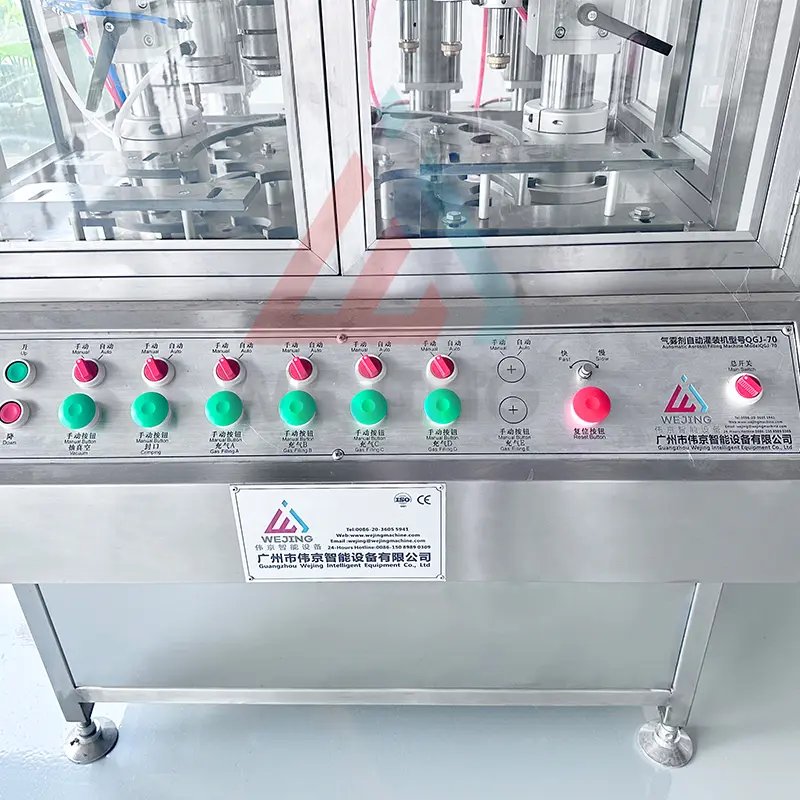

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

This equipment exhibits a production speed ranging from 100 to 120 bottles within a minute. Its filling volume can be adjusted between 30 and 750 milliliters. Notably, it achieves a highly precise repeat filling accuracy of ± 1%, which highlights its outstanding exactitude. It can effortlessly handle 1-inch valves and cans with diameters falling within 35 to 73.85 millimeters and widths not exceeding 310 millimeters. Operating at its best with a compressed air pressure from 0.7 to 0.85 megapascals and a gas consumption rate of 5 cubic meters per minute, it is driven by an AC380V 50HZ power supply. Alternative customization choices involve being suitable for 220V 60HZ or 450V 60HZ power sources.

|

Model Number |

QGJ70 |

|

Place of Origin |

Guangdong |

|

Certification |

CE&ISO9001 |

|

Supply Ability |

10sets per month |

|

Production speed |

60-70 cans / min |

|

Capacity |

30-750ml ( Can Be Customized) |

|

Speed |

High |

|

Gas consumption |

6.5m 3/ Min |

|

Dimension |

22000*3000*2000 mm |

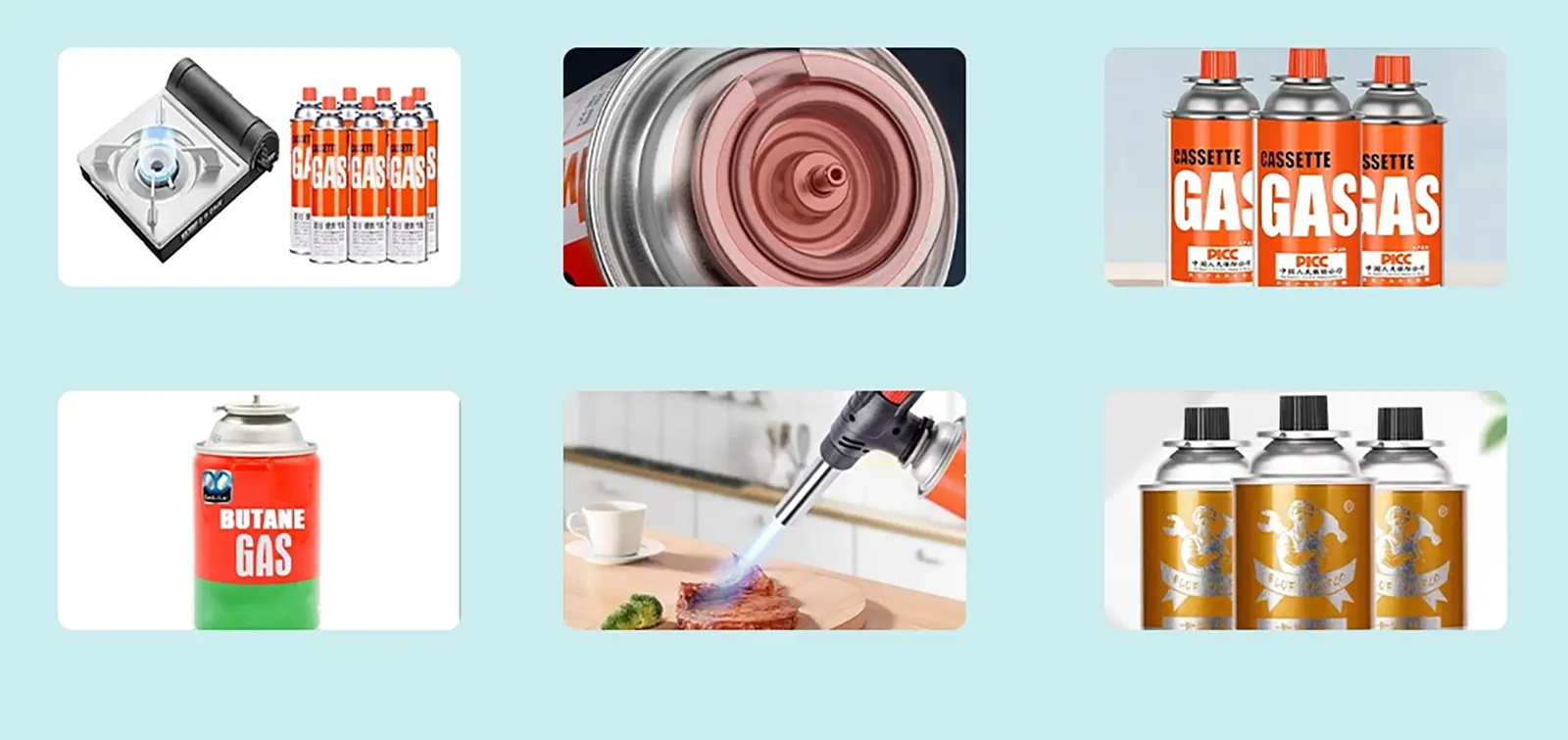

Product Applications

2. Culinary Industry Aid: Assists gas-powered card furnaces in food-related undertakings, guaranteeing a steady stream of gas for culinary tasks such as roasting, baking or dehydration procedures.

3. R&D Enabler: Eases experimental and prototype work in research and development labs where card furnaces are harnessed for substance assessment, thermal scrutiny or chemical combination.

4. Operational Continuity Support: Allows rapid and secure refilling of gas tanks for card furnaces during regular servicing, mending or enhancement, reducing idle time and upholding seamless operation.

5. Crisis Readiness Contribution: Holds a crucial position in emergency response blueprints by speedily refilling gas tanks of standby or emergency card furnaces, ensuring an unbroken heat supply during blackouts or crucial circumstances.